Maintenance – Electronic Products

Subtrol-Plus (Obsolete - See SubMonitor)

Subtrol-Plus - Troubleshooting After Installation

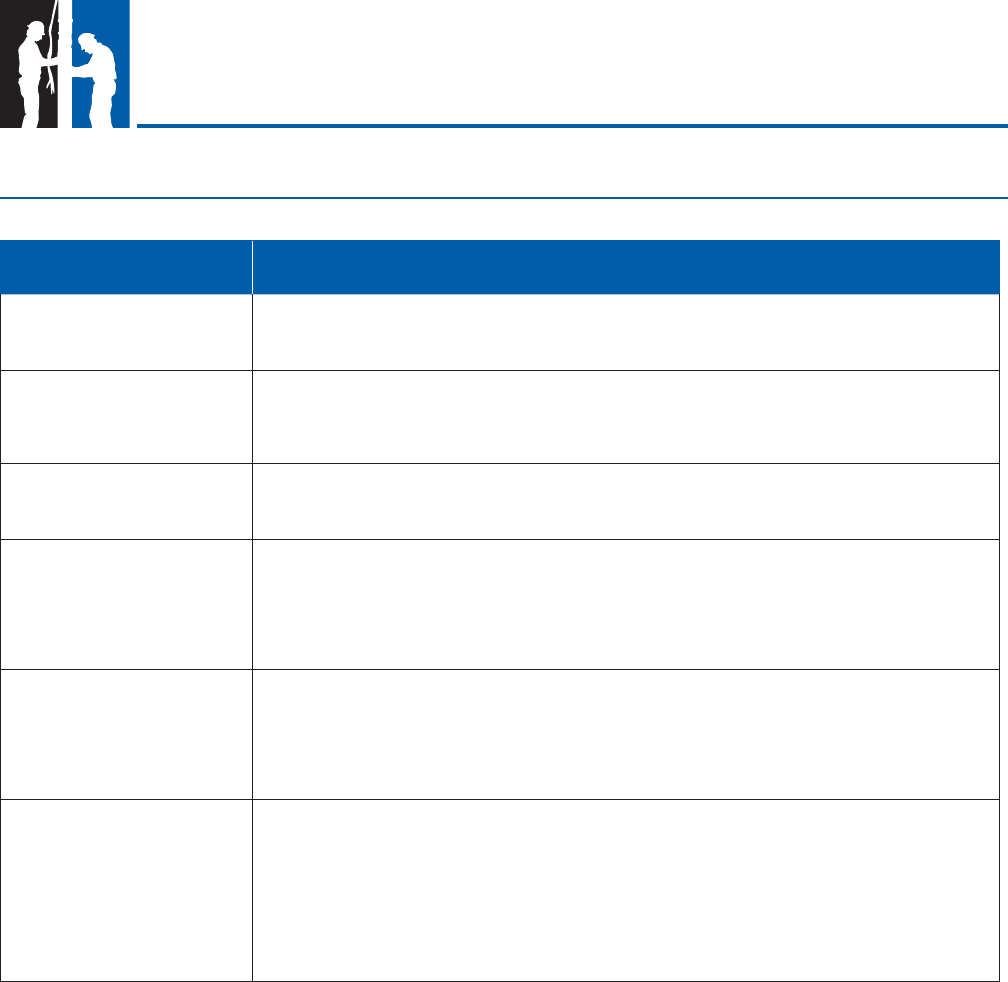

SYMPTOM POSSIBLE CAUSE OR SOLUTION

Subtrol-Plus Dead

When the Subtrol-Plus reset button is depressed and released, all indicator lights should fl ash. If line voltage is

correct at the Subtrol-Plus L1, L2, L3 terminals and the reset button does not cause lights to fl ash, Subtrol-Plus

receiver is malfunctioning.

Green Off Time

Light Flashes

The green light will fl ash and not allow operation unless both sensor coils are plugged into the receiver. If both are

properly connected and it still fl ashes, the sensor coil or the receiver is faulty. An Ohmmeter check between the two

center terminals of each sensor coil connected should read less than 1 ohm, or coil is faulty. If both coils check good,

receiver is faulty.

Green Off Time

Light On

The green light is on and the Subtrol-Plus requires the specifi ed off time before the pump can be restarted after

having been turned off. If the green light is on except as described, the receiver is faulty. Note that a power

interruption when the motor is running will initiate the delay function.

Overheat Light On

This is a normal protective function which turns off the pump when the motor reaches maximum safe temperatures.

Check that amps are within the nameplate maximum on all three lines, and that the motor has proper water fl ow past

it. If overheat trip occurs without apparent motor overheating, it may be the result of an arcing connection somewhere

in the circuit or extreme noise interference on the power lines. Check with the power company or Franklin Electric.

A true motor overheat trip will require at least fi ve minutes for a motor started cold. If trips do not conform to this

characteristic, suspect arcing connections, power line noise, ground fault, or SCR variable speed control equipment.

Overload Light On

This is a normal protective function, protecting against an overload or locked pump. Check the amps in all lines

through a complete pumping cycle, and monitor whether low or unbalanced voltage may be causing high amps at

particular times. If overload trip occurs without high amps, it may be caused by a faulty rating insert, receiver, or

sensor coil. Recheck that the insert rating matches the motor. If it is correct, carefully remove it from the receiver by

alternately lifting sides with a knife blade or thin screwdriver, and make sure it has no pins bent over. If the insert is

correct and its pins are okay, replace receiver and/or sensor coils.

Underload Light On

This is a normal protective function.

A. Make sure the rating insert is correct for the motor.

B. Adjusting the underload setting as described to allow the desired range of operating conditions. Note that a

DECREASE in underload setting is required to allow loading without trip.

C. Check for drop in amps and delivery just before trip, indicating pump breaking suction, and for unbalanced

line current.

D. With the power turned off, recheck motor lead resistance to ground. A grounded lead can cause underload trip.

60