Application – All Motors

Franklin submersible motors are designed primarily for

operation in the vertical, shaft-up position.

During acceleration, the pump thrust increases as its

output head increases. In cases where the pump head

stays below its normal operating range during startup and

full speed condition, the pump may create upward thrust.

This creates upward thrust on the motor upthrust bearing.

This is an acceptable operation for short periods at each

start, but running continuously with upthrust will cause

excessive wear on the upthrust bearing.

With certain additional restrictions as listed in this section

and the Inline Booster Pump Systems sections of this

manual, motors are also suitable for operation in positions

Franklin Electric submersible motors are a water-

lubricated design. The fi ll solution consists of a mixture

of deionized water and Propylene Glycol (a non-toxic

antifreeze). The solution will prevent damage from

freezing in temperatures to -40 °F (-40 °C); motors should

be stored in areas that do not go below this temperature.

The solution will partially freeze below 27 °F (-3 °C),

but no damage occurs. Repeated freezing and thawing

should be avoided to prevent possible loss of fi ll solution.

There may be an interchange of fi ll solution with well

water during operation. Care must be taken with motors

removed from wells during freezing conditions to

prevent damage.

When the storage temperature does not exceed

100 °F (37 °C), storage time should be limited to two

years. Where temperatures reach 100° to 130 °F, storage

time should be limited to one year.

Loss of a few drops of liquid will not damage the motor

as an excess amount is provided, and the fi lter check

valve will allow lost liquid to be replaced by fi ltered well

water upon installation. If there is reason to believe there

has been a considerable amount of leakage, consult the

factory for checking procedures.

The average number of starts per day over a period

of months or years infl uences the life of a submersible

pumping system. Excessive cycling affects the life of

control components such as pressure switches, starters,

relays and capacitors. Rapid cycling can also cause

motor spline damage, bearing damage, and motor

overheating. All these conditions can lead to reduced

motor life.

The pump size, tank size and other controls should be

selected to keep the starts per day as low as practical for

longest life. The maximum number of starts per 24-hour

period is shown in table 3.

Motors should run a minimum of one minute to dissipate

heat build up from starting current. 6" and larger motors

should have a minimum of 15 minutes between starts or

starting attempts.

from shaft-up to shaft-horizontal. As the mounting position

becomes further from vertical and closer to horizontal, the

probability of shortened thrust bearing life increases. For

normal motor life expectancy with motor positions other

than shaft-up, follow these recommendations:

1. Minimize the frequency of starts, preferably to fewer

than 10 per 24-hour period. 6” and 8” motors should

have a minimum of 20 minutes between starts or

starting attempts

2. Do not use in systems which can run even for short

periods at full speed without thrust toward the motor.

Storage

Frequency of Starts

Mounting Position

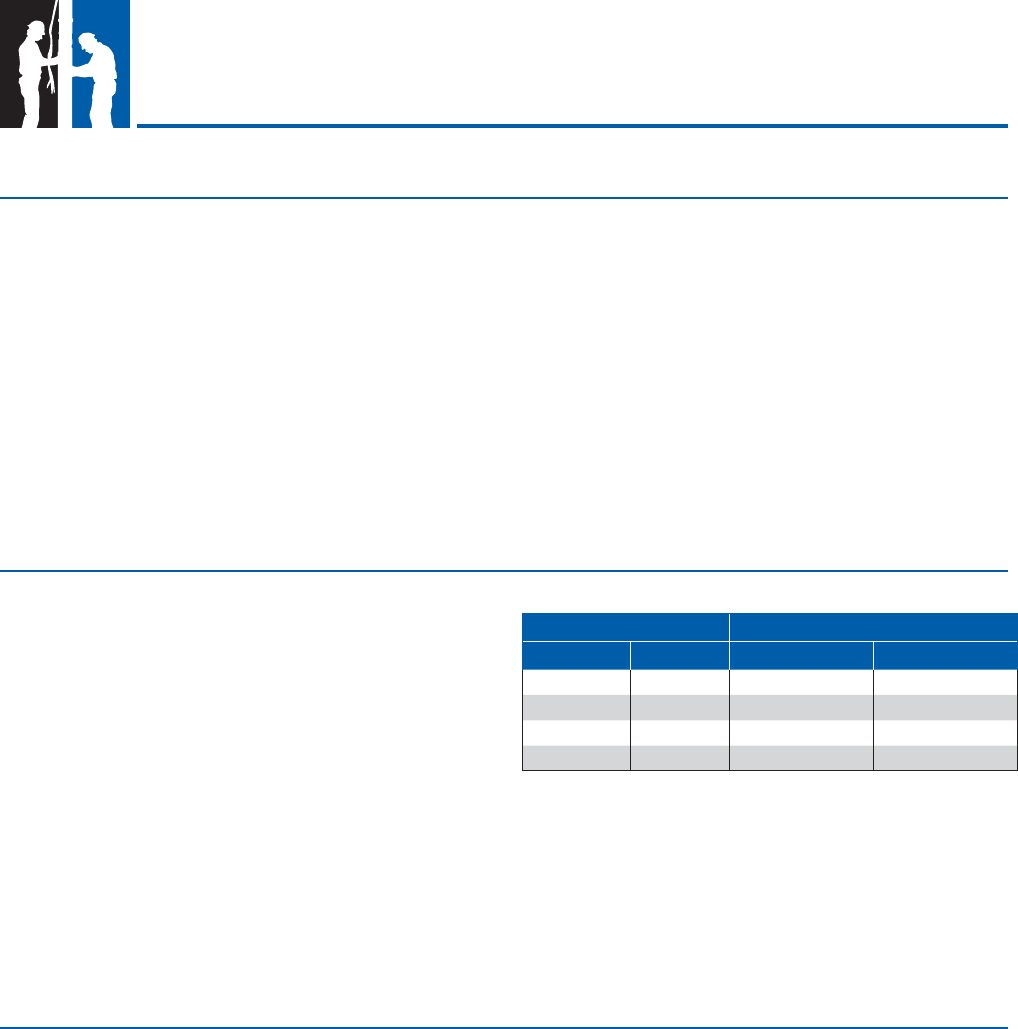

MOTOR RATING MAXIMUM STARTS PER 24 HR PERIOD

HP KW SINGLE-PHASE THREE-PHASE

Up to 0.75 Up to 0.55 300 300

1 thru 5.5 0.75 thru 4 100 300

7.5 thru 30 5.5 thru 22 50 100

40 and over 30 and over - 100

Table 3 Number of Starts

3