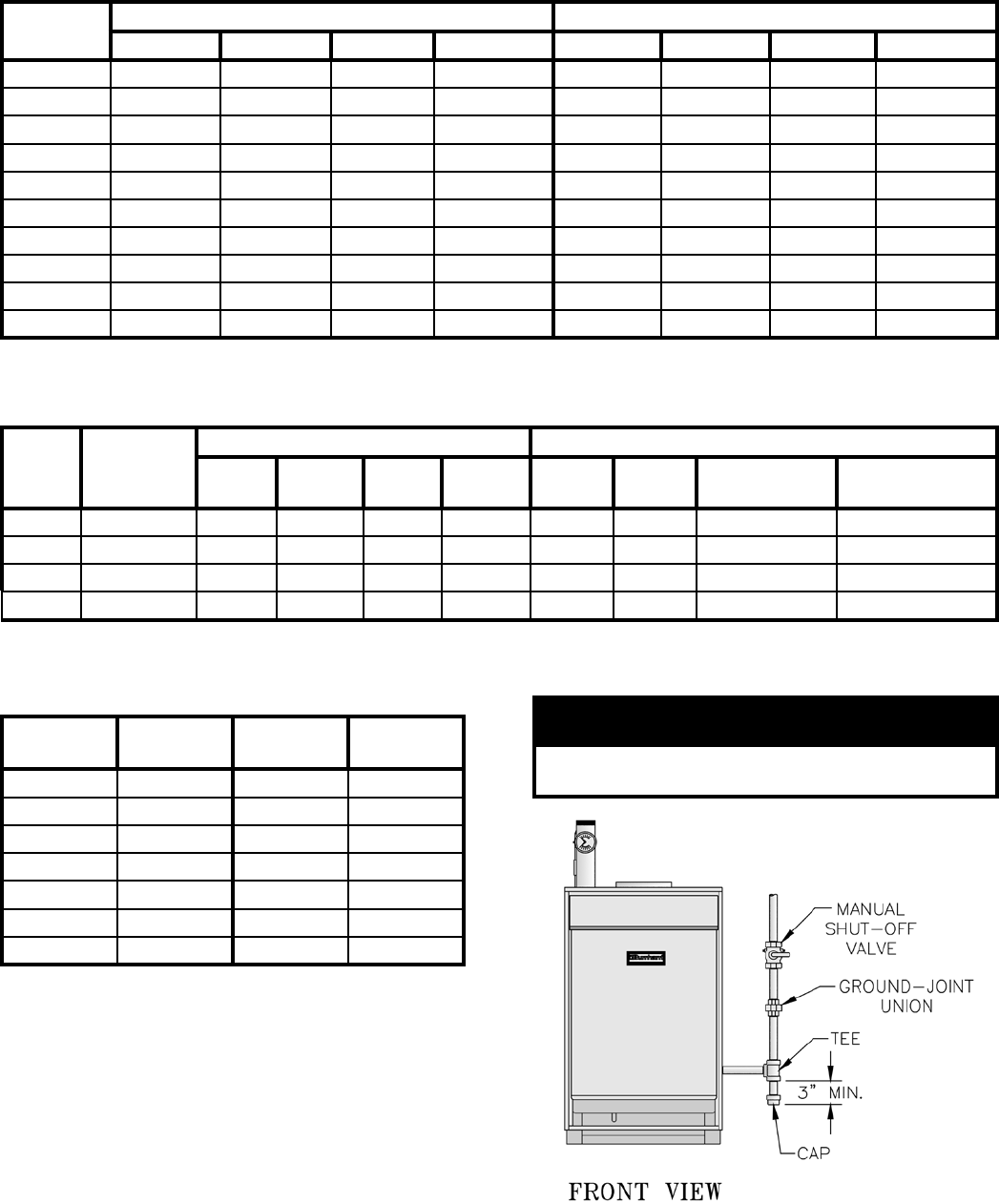

30

Length

(Feet)

0.3 Inch w.c. Pressure Drop 0.5 Inch w.c. Pressure Drop

½ ¾ 1 1¼ ½ ¾ 1 1¼

10 132 278 520 1,050 175 360 680 1,400

20 92 190 350 730 120 250 465 950

30 73 152 285 590 97 200 375 770

40 63 130 245 500 82 170 320 660

50 56 115 215 440 73 151 285 580

60 50 105 195 400 66 138 260 530

70 46 96 180 370 61 125 240 490

80 43 90 170 350 57 118 220 460

90 40 84 160 320 53 110 205 430

100 38 79 150 305 50 103 195 400

Table 6: Maximum Capacity of Schedule 40 Pipe in CFH for Gas Pressures of 0.5 psig or Less

Table 7: Equivalent Lengths of Standard Pipe Fittings & Valves

Pipe

Size

I.D.

(Inches)

Valves (Fully Open) Threaded Fittings

Gate Globe Angle

Swing

Check

90°

Elbow

45°

Elbow

90° Tee, Flow

Through Run

90° Tee, Flow

Through Branch

½” 0.622 0.35 18.6 9.3 4.3 1.6 0.78 1.0 3.1

¾” 0.824 0.44 23.1 11.5 5.3 2.1 0.97 1.4 4.1

1” 1.049 0.56 29.4 14.7 6.8 2.6 1.23 1.8 5.3

1¼” 1.380 0.74 38.6 19.3 8.9 3.5 1.6 2.3 6.9

Specic

Gravity

Correction

Factor

Specic

Gravity

Correction

Factor

0.50 1.10 1.30 1.07

0.55 1.04 1.40 1.04

0.60 1.00 1.50 1.00

0.65 0.96 1.60 0.97

0.70 0.93 1.70 0.94

0.75 0.90 --- ---

0.80 0.87 --- ---

Table 8: Specic Gravity Correction Factors

WARNING

Do not use matches, candles, open ames, or

other ignition source.

Figure 24: Recommended Gas Piping

C. Pressure Test. The boiler and its gas connection must

be leak tested before placing boiler in operation.

1. Protect boiler gas valve. For all testing over ½ psig,

boiler and its individual shut-off valve must be

disconnected from gas supply piping. For testing at

½ psig or less, isolate boiler from gas supply piping

by closing boiler’s individual manual shut-off valve.

2. Locate leaks using approved combustible gas

detector, soap and water, or similar nonammable

solution.