28

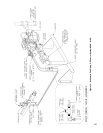

a. A boiler by-pass is recommended for any

installation for improved system temperature

balance, while serving to protect the boiler from

sustained condensing operation. The by-pass

also provides some measure of low return water

temperature protection by reducing ow through

the boiler. See Figure 23.

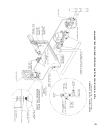

b. A blend pump is recommended to divert hot

supply water into the return when system return

temperatures can periodically dip below 135°F

or when delta T’s rise beyond 40°F because of

control schemes that shut off zone pumps for

extended periods. See Figure 23, Detail “A”.

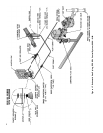

c. Primary/secondary piping with a by-pass is

recommended to provide two points of mixing

when dual temperature systems are used (i.e.

baseboard and radiant heat, outdoor reset

and domestic hot water production, systems

incorporating night setback or multiple zone

pumps on clock schedules). See Figure 23,

Detail “B”.

d. If system three-way valves are used for

temperature modulation, or if the system will

continuously run below 135°F for extended

periods (due to low temperature applications

like snowmelt, heat pump systems or others),

primary/secondary boiler piping with a three-

way valve and return temperature sensor is

recommended. Refer to Burnham RTC Return

Temperature Control Manual and Tekmar Essay

#021 “Mixing Methods and Sizing of Variable

Speed Injection Pumps” for more information on

mixing devices and boiler protection from low

return water temperature.

4. A hot water boiler installed above radiation level

must be provided with a low water cutoff device as

part of installation.

5. A start-up strainer is recommended for all

installations (new and replacement alike) to prevent

system debris and sediment from ending up in the

boilers where it will inhibit heat transfer and may

eventually cause a cast iron section to crack from

overheating.

G. Alliance SL™ Water Heater (if used). Refer to

Alliance SL™ Installation, Operating and Service

Instructions for additional information. Install in same

manner as space heating zone.

WARNING

Burnham Commercial recommends maintaining temperature differential (drop) across the system at

40°F or less and return water temperature at minimum of 135°F.

Continued boiler operation for prolonged periods of time under conditions when temperature differential

across the system exceeds 40°F and/or return water temperature stays below 135°F, may result in premature

boiler failure due to ue gas condensation and/or thermal shock.

If the above conditions exist, to protect a boiler from sustained ue gas condensation and/or thermal

shock, the above-recommended temperatures may be maintained by employing common industry-accepted

mixing methods to provide boiler protection.

Some common methods are boiler by-pass piping, blend pumps, primary secondary piping with a by-

pass, mixing valves and/or variable speed injection pumps.