c. If combustion air is taken from the outdoors through a

single opening or duct (horizontal or vertical) commencing

within 12 in. of the top of the confined space, the opening

and duct must have at least 1 sq in. of free area per 3000

Btuh of the total input for all equipment within the confined

space and not less than the sum of the areas of all vent

connectors in the confined space. Equipment clearances to

the structure shall be at least 1 in. from the sides and back

and 6 in. from the front of the appliances. See Table 2 and

Fig. 8.

When ducts are used, they must be of the same cross sectional area

as the free area of the openings to which they connect. The

minimum dimension of ducts must not be less than 3 in.

INSTALLATION

Step 1—Upflow Installation

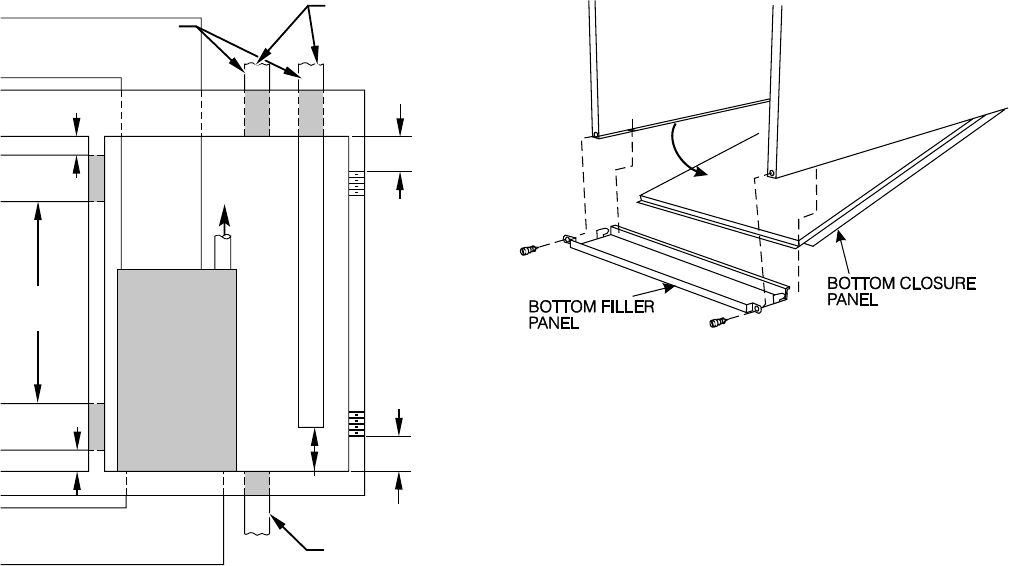

BOTTOM RETURN AIR INLET

These furnaces are shipped with bottom closure panel installed in

bottom return-air opening. Remove and discard this panel when

bottom return air is used. To remove bottom closure panel,

perform the following:

1. Tilt or raise furnace and remove 2 screws holding bottom filler

panel. (See Fig. 9.)

2. Rotate bottom filler panel downward to release holding tabs.

3. Remove bottom closure panel.

4. Reinstall bottom filler panel and screws.

SIDE RETURN AIR INLET

These furnaces are shipped with bottom closure panel installed in

bottom return-air opening. This panel MUST be in place when

only side return air is used.

NOTE: Side return-air openings can be used in UPFLOW and

most HORIZONTAL configurations. Do not use side return-air

openings in DOWNFLOW configuration.

LEVELING LEGS (IF DESIRED)

In upflow position with side return inlet(s), leveling legs may be

used. (See Fig. 10.) Install field-supplied, 5/16 X 1 1/2 in. (max)

corrosion-resistant machine bolts, washers and nuts.

NOTE: Bottom closure must be used when leveling legs are used.

It may be necessary to remove and reinstall bottom closure panel

to install leveling legs. To remove bottom closure panel, see Fig.

9.

To install leveling legs:

1. Position furnace on its back. Locate and drill a hole in each

bottom corner of furnace. (See Fig. 10.)

2. For each leg, install nut on bolt and then install bolt and nut in

hole. (Install flat washer if desired.)

3. Install another nut on other side of furnace base. (Install flat

washer if desired.)

4. Adjust outside nut to provide desired height, and tighten inside

nut to secure arrangement.

5. Reinstall bottom closure panel if removed.

Step 2—Downflow Installation

NOTE: For downflow applications, this furnace is approved for

use on combustible flooring when any one of the 3 accessories are

used:

• Special Base, KGASB

• Cased Coil Assembly Part No. CD5 or CK5

• Coil Box Part No. KCAKC

1. Determine application being installed from Table 3.

2. Construct hole in floor per Table 3 and Fig. 11.

3. Construct plenum to dimensions specified in Table 3 and Fig.

11.

4. If downflow subbase, KGASB is used, install as shown in Fig.

12. If Coil Assembly Part No. CD5 or CK5 or Coil Box Part

No. KCAKC is used, install as shown in Fig. 13.

Fig. 8—Confined Space: Air for Combustion and

Ventilation from Outdoors

A02165

1 SQ IN.

PER

4000

BTUH*

DUCTS

TO

OUTDOORS

1 SQ IN.

PER 4000

BTUH

*

AIR

DUCTS

VENT

THROUGH

ROOF

D

B

A

C

E

1 SQ IN.

PER 4000

BTUH

*

DUCT

TO

OUTDOORS

AIR DUCTS

1 SQ IN.

PER 2000

BTUH

*

1 SQ IN.

PER 2000

BTUH

*

DUCTS

TO

OUTDOORS

12″ MAX

12

″ MAX

12″ MAX

Use any of the following

combinations of openings:

A & B C & D D & E F & G

NOTE:

*Minimum dimensions of 3 in.

CONFINED

SPACE

12″

MAX

12″

MAX

OUTDOORS

1 SQ IN.

PER

4000

BTUH*

F

G

Fig. 9—Removing Bottom Closure Panel

A02098

8

→