CSA (A.G.A. and C.G.A.) listed gas conversion kit is required

to convert furnace for use with propane gas.

11. See Fig. 2 for required clearances to combustibles.

12. Maintain a 1-in. clearance from combustible materials to

supply air ductwork for a distance of 36 inches horizontally

from the furnace. See NFPA 90B or local code for further

requirements.

13. These furnaces SHALL NOT be installed directly on carpet-

ing, tile, or any other combustible material other than wood

flooring. In downflow installations, factory accessory floor

base MUST be used when installed on combustible materials

and wood flooring. Special base is not required when this

furnace is installed on manufacturer’s Coil Assembly Part No.

CD5 or CK5, or when Coil Box Part No. KCAKC is used.

INTRODUCTION

This 4–way multipoise Category I fan-assisted furnace is CSA

(A.G.A. and C.G.A.) design-certified for natural and propane gas

and for installation in alcoves, attics, basements, closets, utility

rooms, crawlspaces, and garages. A fan-assisted furnace is an

appliance equipped with an integral mechanical means to either

draw or force products of combustion through the combustion

chamber and/or heat exchanger. The furnace is factory-shipped for

use with natural gas. A CSA (A.G.A. and C.G.A.) listed gas

conversion kit is required to convert furnace for use with propane

gas. This furnace is not approved for installation in mobile homes,

recreational vehicles, or outdoors.

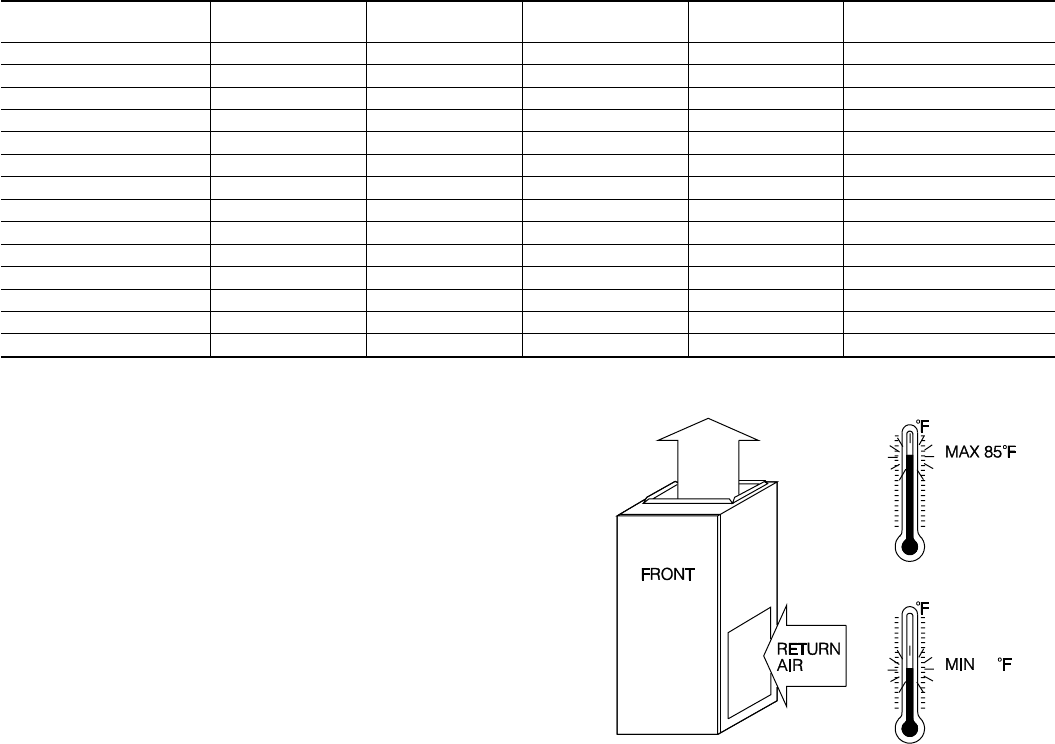

This furnace is designed for minimum continuous return-air

temperature of 60°F db or intermittent operation down to 55°Fdb

such as when used with a night setback thermostat. Return-air

temperature must not exceed 85°F db. Failure to follow these

return-air limits may affect reliability of heat exchangers, motors,

and controls. (See Fig. 3.)

For accessory installation details, refer to the applicable instruction

literature.

NOTE: Remove all shipping brackets and materials before oper-

ating the furnace.

CODES AND STANDARDS

Follow all national and local codes and standards in addition to

these instructions. The installation must comply with regulations

of the serving gas supplier, local building, heating, plumbing, and

other codes. In absence of local codes, the installation must

comply with the national codes listed below and all authorities

having jurisdiction.

In the United States and Canada, follow all codes and standards for

the following:

Step 1—Safety

• US: National Fuel Gas Code (NFGC) NFPA 54–2002/ANSI

Z223.1–2002 and the Installation Standards, Warm Air Heating

and Air Conditioning Systems ANSI/NFPA 90B

• CANADA: CAN/CGA-B149.1–and .2–M00 National Standard

of Canada. Natural Gas and Propane Installation Codes (NSC-

NGPIC)

Step 2—General Installation

• US: Current edition of the NFGC and the NFPA 90B. For

copies, contact the National Fire Protection Association Inc.,

Batterymarch Park, Quincy, MA 02269; or for only the NFGC,

contact the American Gas Association, 400 N. Capitol, N.W.,

Washington DC 20001 or www.NFPA.org.

• CANADA: NSCNGPIC. For a copy, contact Standard Sales,

CSA International, 178 Rexdale Boulevard, Etobicoke (Tor-

onto), Ontario, M9W 1R3 Canada

Step 3—Combustion and Ventilation Air

• US: Section 5.3 of the NFGC, Air for Combustion and

Ventilation

Table 1—Dimensions (IN.)

UNIT SIZE A B C

VENT

CONN*

SHIP WT. (LB)

045-08/024045 14-3/16 12-9/16 12-11/16 4 104

045-12/036045 14-3/16 12-9/16 12-11/16 4 107

070-08/024070 14-3/16 12-9/16 12-11/16 4 111

070-12/036070 14-3/16 12-9/16 12-11/16 4 115

070-16/048070 17-1/2 15-7/8 16 4 123

090-14/042090 17-1/2 15-7/8 16 4 126

090-16/048090 21 19-3/8 19-1/2 4 139

090-20/060090 21 19-3/8 19-1/2 4 145

110-12/036110 17-1/2 15-7/8 16 4 134

110-16/048110 21 19-3/8 19-1/2 4 145

110-22/066110 21 19-3/8 19-1/2 4 151

135-16/048135 21 19-3/8 19-1/2 4 148

135-22/066135 24-1/2 22-7/8 23 4 163

155-20/060155 24-1/2 22-7/8 23 4 170

*5” or 6” vent connector may be required in some cases.

Fig. 3—Return Air Temperature

A02055

60

4

→

→

→

→