REMOTE INTELLIGENT SENSOR - AREA MONITOR

Instruction 2772-0803 Page 4-5

NOTE: If it is not possible to achieve a

satisfactory average tape step length, please

refer to additional information in

Section 4.21.2.

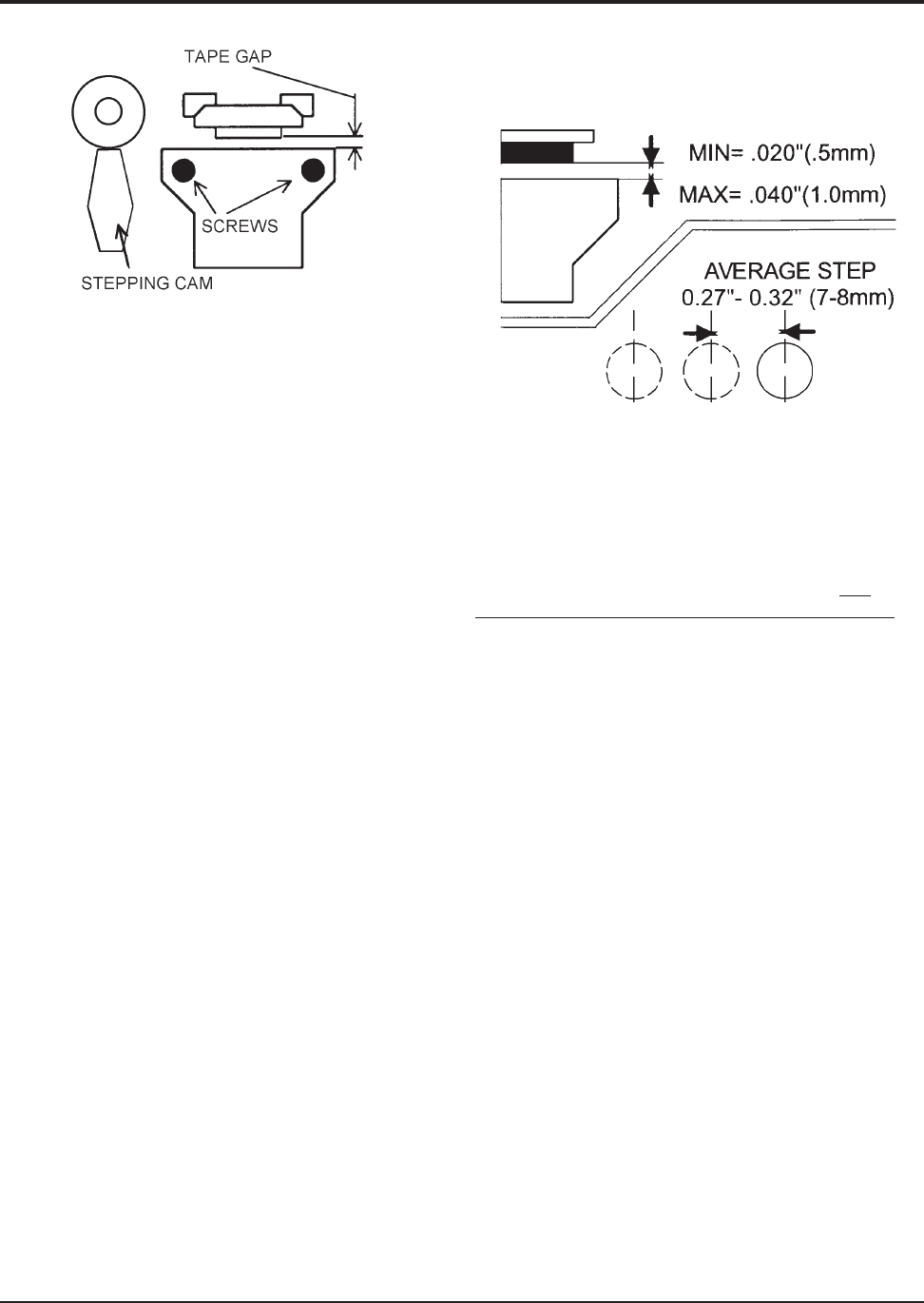

Figure 4-7. Summary of Gate & Step Values

4.10.7 WHAT TO DO IF CLEANING DOES NOT

RECTIFY THE PROBLEM. If performance cannot

be improved, or if the change is marginal, it will be

necessary to replace the optics block. A new optics

block can be ordered from your distributor. When

ordering the replacement block, specify the

RIS

system gas type and range, also the serial number.

This information will ensure that the correct item is

supplied.

It should be appreciated that if the block is

replaced the original calibration of the instrument is

no longer valid. It may be assumed that, because of

manufacturing methods and testing, performance

with a replacement block will be within 10% of the

original. Factory re-calibration against gas is recom-

mended as soon as is practicable.

A replacement block carried as a spare against

future need is a wise precaution for those applica-

tions where contamination of the input tube and

optics block is a problem.

4.11 CHANGING A PUMP

Providing that care is taken, this is not a

difficult procedure.

4.11.1 PREPARATION. Have available a replace-

ment pump of the correct type. RIS systems with a

Flow Rate of 200 mL/min. or less are fitted with the

low flow pump and RIS’s with a Flow Rate higher

than 200 mL/min. are fitted with the high flow

pump. These catalog numbers specify the pump

complete with mounting bracket ready to fit.

Warn that the system is being taken out of

operation and that alarms may be activated during

the work. Remove external power from the RIS, open

the door and turn off SW1.

Figure 4-6. Stepping Clamp Vertical

With the stepping cam vertical, and gate

opening lever in the gate closed position, the optics

block can be replaced and the two screws put in

loosely. Position the optics block so that there is a

gap of 0.020" to 0.040" (0.5mm to 1.0mm) between

the two halves of the gate.

Ensure that the gap is parallel when it is

measured. Note that the plastic tubes connecting

the moving part can cause it to twist a little in its

pivot. This can make the gap closer at the top or the

bottom.

After initially setting the gap, tighten the block

fixing screws to lock the optics block in position.

Replace the connector (with the switch ‘off ’),

then, verify that the tape steps correctly as follows.

Place a length of tape in the gate. This can be

done by pulling a length out of a cassette which can

be placed on top of the unit, or held in one hand.

Avoid touching tape with bare fingers.

Switch ‘on’, and press the tape reset button to

step on the tape. Mark the edge of the block on the

tape with a pencil. Repeat the process until 4 or 5

steps are marked on the tape. Measure the length

of the tape steps and take an average. The average

step should be between 0.27" and 0.32", (7 to 8 mm).

If the steps are much longer, the cassette life

will be less than the quoted 30-day maximum. In

this case, the position of the optics block may be

adjusted by repeating the above process, but

reducing the gap gradually. Continue until a tape

step of approximately 0.32"(8 mm) is achieved. Do

not reduce the gap to less than 0.020" (0.5 mm) or

tape drag in the gate may occur. This condition may

be aggravated if the tape gets damp. Tape breakage

can occur under these conditions.

NOTE: In some cases it may not be

possible to reduce the tape gap below about

0.030" (0.75 mm), in this case leave it set

at that value.