REMOTE INTELLIGENT SENSOR - AREA MONITOR

Page 4-4 Instruction 2772-0803

Repeat several times, also with the gate open.

If a can of pressurized air is available, carefully

position tube at the tape side of the gate and blow

again several times. Suitable cans of air are usually

available from photographic suppliers. A mechani-

cal pump or bellows can be used but it may not be

possible to blow from the tape side.

NOTE: Take care to ensure that any dirt,

not trapped by the tape in the open gate, is

removed. Clean both holes in twin hole

blocks.

Carefully clean holes in block using a small

amount of cotton wool twisted onto a sliver of wood.

A normal sized cotton ‘bud’ or swab may be too

large. If necessary, use a little residue free solvent

spray on cotton wool as well. Afterwards, make sure

that no debris has been left during cleaning process

by blowing through again.

At this stage check the light levels to see if the

cleaning has effected an adequate improvement. If

it has, carefully reassemble the input tubes and,

after replacing a serviceable cassette, recheck the

light levels and put the system back into service.

CAUTION

Make sure that the input tubes are properly

engaged in the block or the instrument will

not monitor accurately (Figures 2-4 & 2-5).

4.10.5 DIRECT CLEANING OF THE LED’S

AND PHOTO DIODES. If the limited cleaning

detailed above does not effect an adequate improve-

ment in the light levels perform the following.

NOTE: This procedure requires removal of

the optics block and should not be done

without good reason.

Remove the cassette. If the input tubes have

not already been removed, do so now. Take out the

two slot-head screws securing the optics block to

the mechanical chassis.

Carefully lift block without disconnecting the

leads or putting them under undue strain. It is now

possible to insert a small swab into the two holes in

the block. This should be done from the tape side.

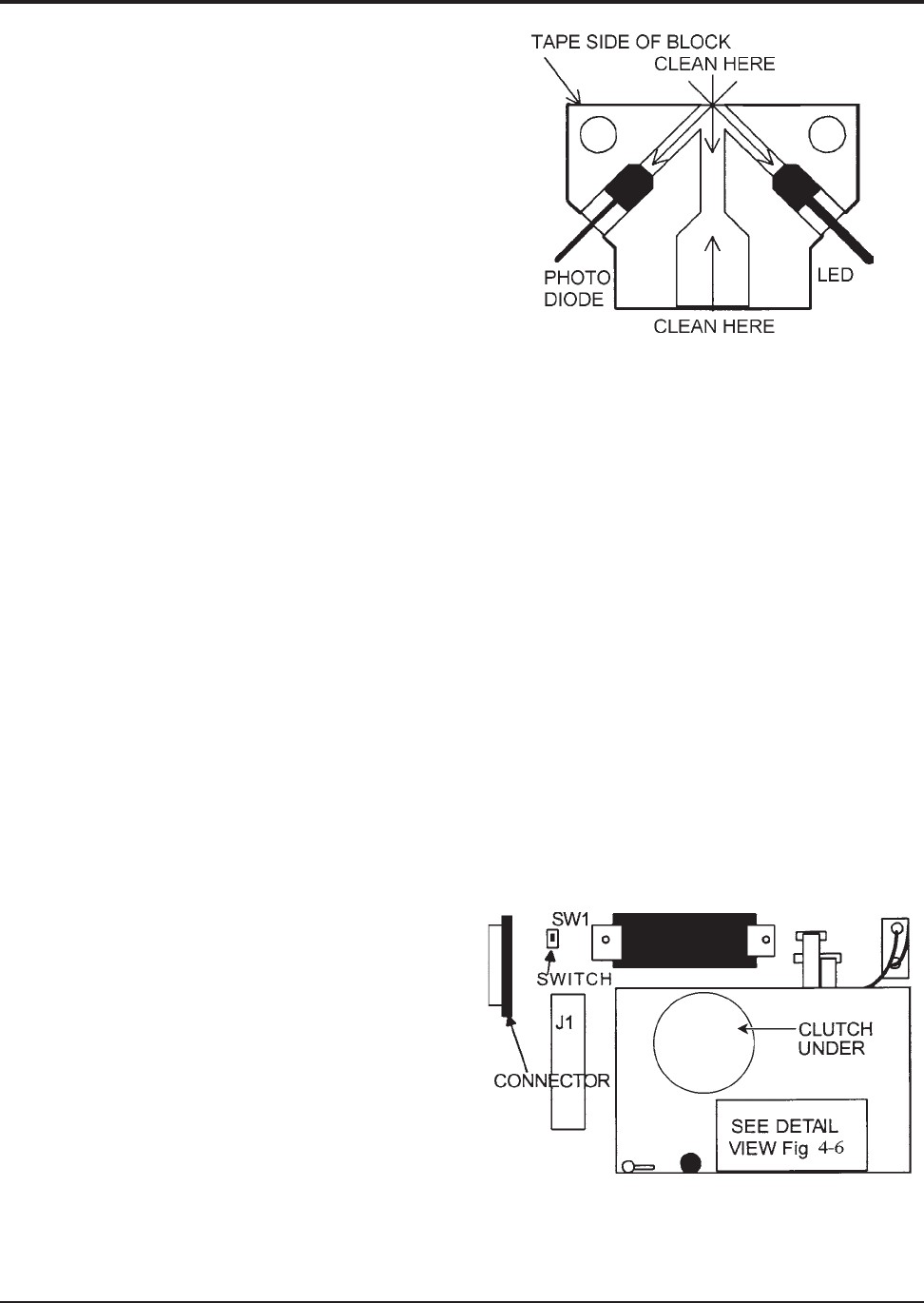

Gently find the angled cavities at the end of

which are mounted the optic devices (Figure 4-4),

clean both sides. Make sure that no lint or other

particles are left behind, blow out if necessary.

Figure 4-4. Cleaning Optics block

4.10.6 REPLACING THE OPTICS BLOCK.

Care is required when replacing the Optics block so

that it is correctly positioned relative to the other

half. It is first necessary to position the tape ad-

vance cam (on the left of the gate) so that it is

vertical. This can be achieved in one of two ways:

With switch SW1 turned off, find the take up

clutch on the mechanical chassis beneath the top

plate as shown in Figure 4-5. Turn the clutch by

moving the light colored gear at the bottom of the

clutch assembly (this is furthest away from the top

plate and it can be seen without taking the me-

chanical chassis out of the RIS).

The clutch must be turned until stepping cam is

vertical as shown in Figure 4-6. The gear is a little

difficult to start turning because of the ratio.

The cam may also be positioned by turning switch

SW1 ‘off ’, remove the connector at the top left of the

unit as shown in Figure 4-5 and switch ‘on’ again, the

stepping cam will turn continuously. By turning SW1

‘off ’ at the appropriate point in the cam’s rotation, it

may be positioned vertically as shown.

Figure 4-5. Finding Take Up Clutch