REMOTE INTELLIGENT SENSOR - AREA MONITOR

Instruction 2772-0803 Page 3-1

Effective purging requires the enclosure to be

properly sealed. Ensure that the cable glands and

the door are air tight. Unused cable glands can be

tightened onto a short piece of cable.

Purge inlet and exhaust ports can be piped to a

remote location, where this is necessary.

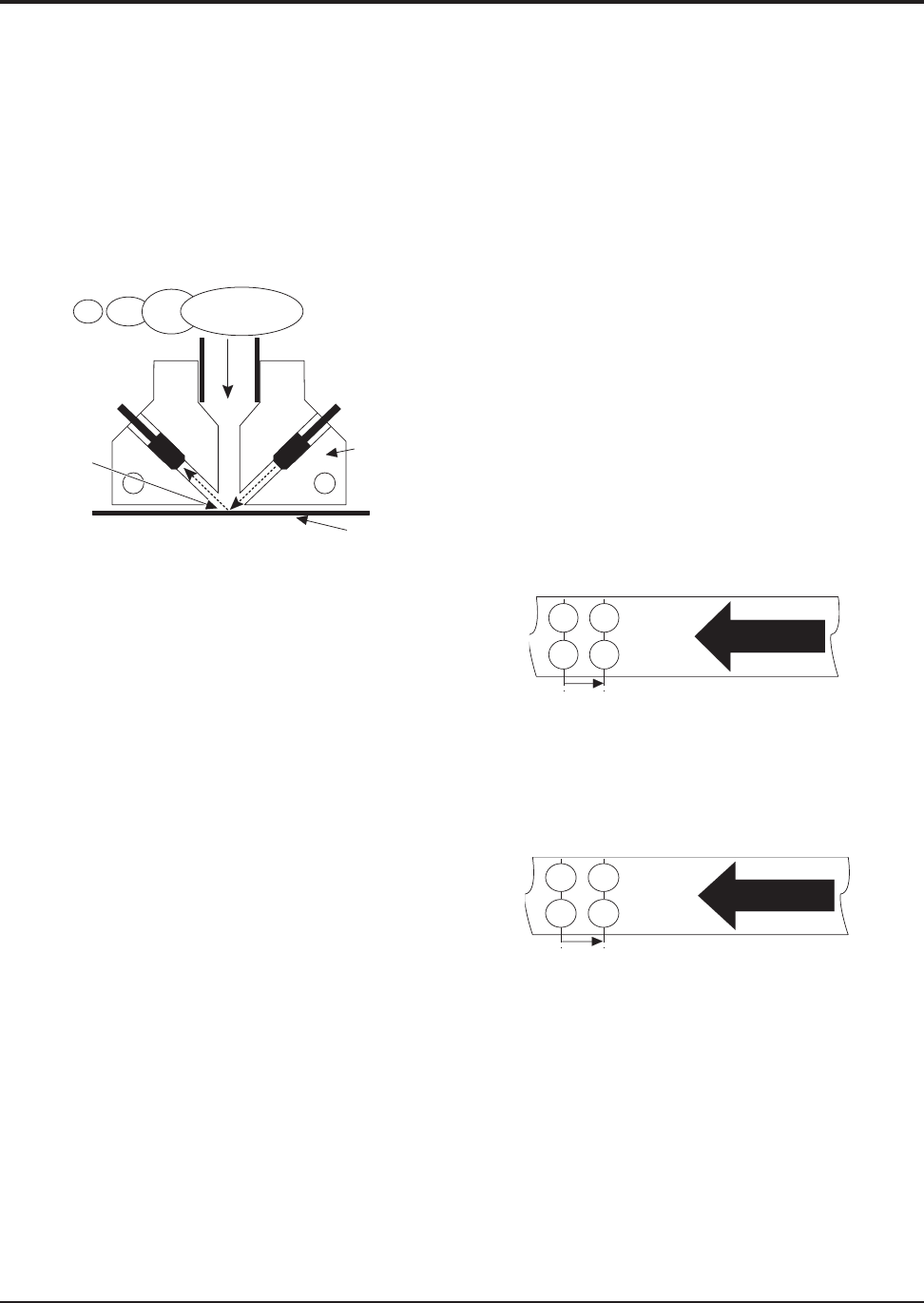

3.1.2 TWIN TRACK TAPE SAMPLING. At

start-up the incoming sample is passed through the

lower tape half (track 1). When that sampling period

is complete, the microprocessor decides if a stain has

formed on the tape. If not, the next sample is again

passed through the same spot on track 1. Conversely

if a stain was formed, the second sample is switched

to pass through the upper half (track 2). The same

sequence occurs at the end of that sample period and

track 2 is reused if no stain is detected.

At this point the tape is stepped on and the next

sample passed through the next track 1 spot. Figure

3-2 shows the sequence where no stain develops and

the maximum of four sample periods occurs before

the tape is stepped.

Figure 3-2. No Stain, Both Tracks Used Twice

Figure 3-3 shows that only two sample periods

per tape step occur if significant stains develop on

the tape.

Figure 3-3. Stain On Tape, Both Tracks Used Once

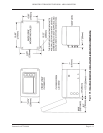

3.1.3 TAPE REFERENCE MEASUREMENT. At

the start of each sample period, the tape spot being

used is scanned by the light pulse (generated by the

optics system), see Figure 3-1. The value of the

reflected light is measured and stored as the refer-

ence against which the light value, during and at the

end of the sample period, is assessed..

3 SYSTEM OPERATION

AND FEATURES

3.1 COMPLETE SAMPLING

SEQUENCE

The sequence starts with system and cassette being

purged before gas sampling starts. In addition, a

reference light level reading is taken from the fresh

tape spot under the optics block.

Figure 3-1. Sampling Sequence

During the sampling period the tape spot is

scanned every two seconds. This frequent scanning

detects the change in the reflected light value that

occurs if a stain develops.

If no stain, or a low density stain, is detected,

sampling continues for a fixed four minutes. At the

end of this time calculated concentration for that

cycle is displayed and the next cycle starts.

The development of a significant stain shortens

the sampling cycle and the concentration value is

displayed immediately, as described in more detail

below.

When a concentration above alarm set point is

detected, the gas alarm relay/s opens to initiate

external alarm systems and warning devices. This

is in addition to the visual warning display.

3.1.1 AUTOMATIC PURGE CYCLE. A purge

sequence occurs after every tape step. The pump

runs at a higher Flow Rate for 10 seconds; air

inside the tape cassette, and the enclosure, is

exchanged for filtered air. The incoming air is

filtered as it passes through a ‘scrubber’ filter in

the cassette. This is shown in the diagram in

Figure 2-8.

Purging prevents the build up of gas in the

system, and in the cassette where it could pre-

expose the tape. The ‘scrubber’ filter is automati-

cally renewed at each cassette change.

TAPE

3/4 7/8

1/2 5/6

STEP

4 SAMPLE PERIODS OF 4 MINUTES EACH

= 16 MINUTES PER TAPE STEP

TRACK 2

TRACK 1

TAPE

2 4

1 3

STEP

2 SAMPLE PERIODS PER STEP. EACH SAMPLE

PERIOD IS A MAX OF 4 MINUTES, OR LESS IF

THE STAIN IS SIGNIFICANT = 8 MINUTES PER

TAPE STEP

TRACK 2

TRACK 1

PHOTO

DIODE

LIGHT

REFLECTED

OFF TAPE

SURFACE

INCOMING

SAMPLE

LIGHT

EMITTING

DIODE

OPTIC

BLOC

K

TAPE