GT INSTALLATION AND OPERATION INSTRUCTIONS Page 5

The GT condensing gas boiler is a high efficiency

boiler utilizing induced power venting. It is designed

to be vented directly to the outdoors using the venting

methods and materials detailed in this section. The

vent system must be both gas tight and watertight. All

horizontal vent piping must be sloped back to the boiler

a minimum of 1/4 in/ft, 21mm/m of vent.

NOTE: Steps must be taken to ensure that condensate

does not collect in the venting system or the boiler

will not operate properly.

This boiler may be vented using the following materials,

but local codes must be followed:

• GT150 & 200: 3 in, 76 mm, PVC Sch.40 solid core

pipe, CPVC Sch.40 pipe, AL29-4C Flex Stainless Vent

or AL29-4C Rigid Stainless Vent.

• GT-400: 4 in, 102 mm or 6 in, 152 mm, PVC Sch.40

solid core pipe, CPVC Sch.40 pipe, AL29-4C Flex

Stainless Vent or AL29-4C Rigid Stainless Vent.

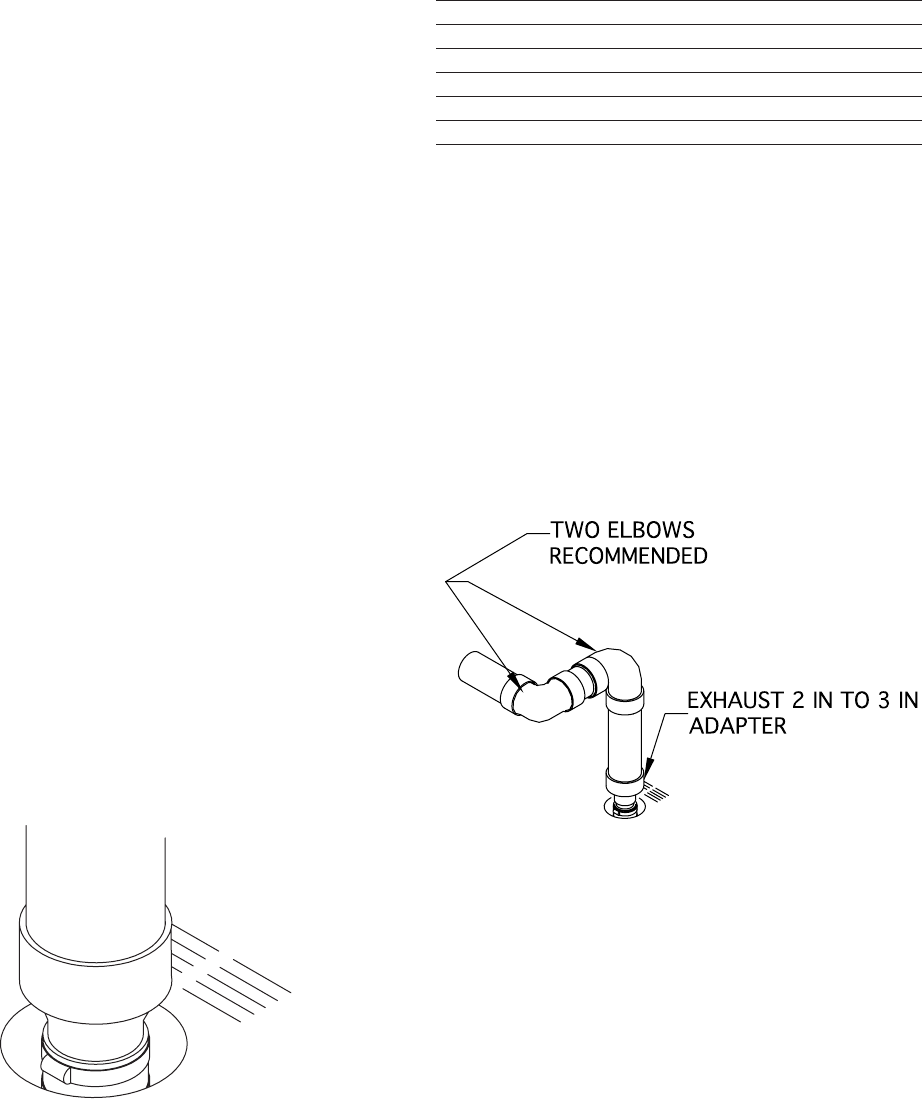

CAUTION: All vent systems must be fully supported

by the building structure. The vent connection and

vent piping MUST be perfectly aligned to the boiler

connection, Figure 3. It MUST NOT APPLY ANY

WEIGHT OR LATERAL FORCE TO THE FLUE BOX or

the fl ue box will be damaged voiding the warranty!

Appropriate adapters must be used to increase the

2 in, 51 mm vent collar to 3 in, 76 mm at the boiler,

GT-150 & 200, Figure 3. On the GT-400 the 4 in,

102 mm long 4 inch diameter ABS pipe provided with

the boiler must be inserted into the exhaust connection

on the top of the boiler and tightened in place with the

supplied clamp.

Figure 3- Vent Pipe To Boiler Attachment

The maximum combined equivalent vent and intake

pipe lengths are listed in Table 2. The length specifi ed

is the equivalent vent length added to the equivalent

intake length.

Table 2 - Vent & Air Intake System Sizing

Model Equivalent Combined Vent & Air Intake

Number System Length (see note)

GT-150 105 ft, 32 m

GT-200 105 ft, 32 m

GT-400 4" - 30 ft, 9 m 6" - 65 ft, 20 m

PGT-150 50 ft, 15 m

PGT-200 50 ft, 15 m

PGT-400 4" - 30 ft, 9 m 6" - 65 ft, 20 m

Note: Subtract 5 ft, 1.5 m, for each 90° elbow except for the vent and

air intake elbows. These don’t need to be considered. The length of

the air inlet system must never exceed the length of the vent system.

The vent system length may exceed the air inlet system length by no

more than 20 equivalent ft, 6.1 equivalent m.

HORIZONTAL

DIRECT VENT SYSTEMS

Read the information in the GENERAL VENTING

GUIDELINES section. It is recommended that two

elbows be used, so that the 1/4 in/ft, 21mm/m slope of

the horizontal vent system does not affect the vertical

plumb of the pipe connected to the boiler, Figure 4.

Figure 4 - Vent System Attachment

When horizontal vent runs exceed 5 ft, 1.5m, they must

be supported at 3 ft, 0.9 m, intervals with overhead

hangers, 4 ft, 1.2 m for 6" pipe. The vent system must

be pitched down, toward the boiler, 1/4 in/ft, 21mm/m.

of vent. Structural penetrations must be made using

approved thimbles.