GT INSTALLATION AND OPERATION INSTRUCTIONSPage 30

The gas supply pressure to the boiler while running

at maximum rate must be between 4 to 9 in, 102 to

229 mm, W.C. for natural gas installations; 9 to 12 in, 229

to 305 mm, W.C. for propane installations. This pressure

can be measured on the gas valve using a manometer,

Figure 41 or 42. Ensure that the regulator is capable of

maintaining this pressure under all operating conditions.

The gas valve is also equipped with a manifold pressure

port, Figure 41 or 42.

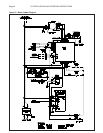

Figure 41 - Gas Valve Layout, GT-150 & 200

Figure 42 - Gas Valve Layout, GT-400

Ignition System

A. Connect a manometer to the line pressure port

shown in Figure 41 or 42. Make sure that the gas

supply piping has been purged of air and that all

gas joints up to the gas valve have been thoroughly

checked for leaks. Wait at least fi ve minutes for any

gas to dissipate before turning on the electrical

power.

B. Read, understand and follow the operating

instructions below.

C. Raise the thermostat at least 5 degrees above the

room temperature. The boiler should enter the pre-

purge mode before energizing the silicon carbide

igniter. Once the igniter is hot, the main gas valve

will open and the burner should light. If the burner

fails to light the system will make three more ignition

attempts. If the burner has not lit after the last

ignition try, the gas valve will close and the system

will go into lock out. DO NOT attempt to reset the

system until the ignition system has been inspected

and the problem resolved. Once the problem has

been resolved and 5 minutes have passed since

the last ignition attempt, reset the system by turning

the thermostat to it’s lowest setting and then back

to where it was or by momentarily interrupting the

electrical power to the boiler.

D. With the burner in operation close the manual shutoff

valve in the gas supply line. As soon as the burner

fl ame goes out, open the manual shutoff valve. A

normal ignition sequence should take place.

E. With the burner in operation, interrupt the power to the

control circuit by lowering and raising the thermostat.

A normal ignition sequence should follow.

F. To test the ignition safety shutoff device, close the

manual shutoff valve in the gas supply line. Within 6

seconds of main burner fl ame extinction, the main

gas valve solenoid should close with an audible noise.

The igniter should glow and make three attempts at

ignition. After unsuccessfully attempting to light the

burner the ignition module should lock out.

Input Screw

Manifold Pressure

Line Pressure