42

Preparation

Check Power Supply

With multi-meter at incoming power, check voltage

between:

Hot - Common (≈120 VAC)

Hot - Ground (≈120 VAC)

Common - Ground (< 1 VAC)

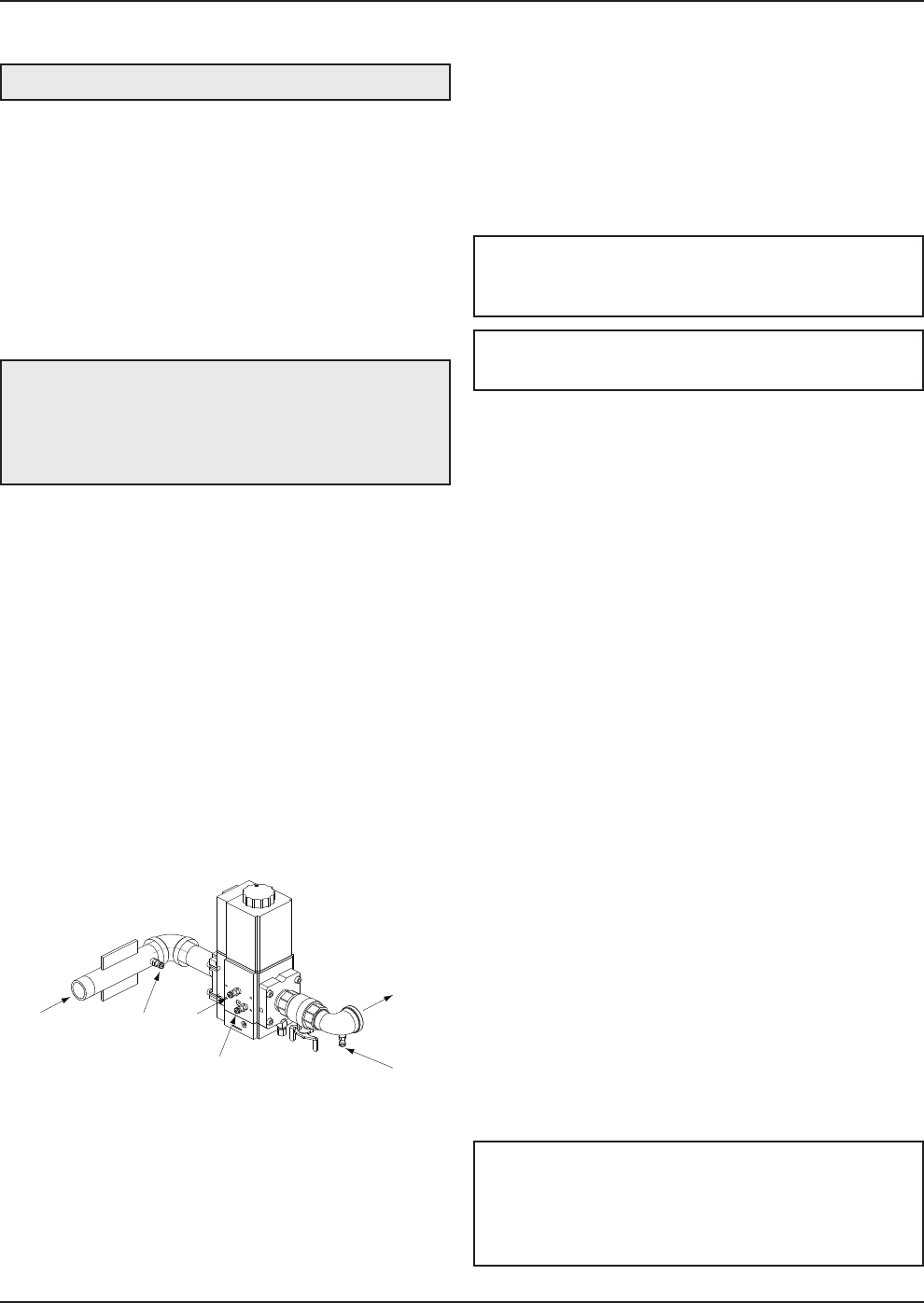

Attach Manometers to Measure Pressures

1. Turn off main gas valve.

2. Attach (1) 12” scale manometer to an upstream

bleedle valve on the gas supply pipe to the heater

(Measure point “A” in Fig. 47).

3. Attach (1) 24” scale manometer to the manifold

pressure tap located on the elbow downstream of

the valve (Measure point “D” in Fig. 47).

4. Attach (1) 12” scale manometer near the fan-prov-

ing switch. Pull black cap from air pressure switch

tee and connect the manometer. NOTE: Retain

caps for reinstallation later.

Check Gas Supply Pressure

1. Slowly turn on main gas shut-off valve.

2. Read the gas supply pressure from the manome-

ter; minimum supply pressure for natural gas is 4.0

in. WC, recommended supply is 7.0 in. WC, mini-

WARNING: If Common - Ground is > 1 VAC,

STOP: Contact electrician to correct ground failure.

Failure to do this may burn out 120V-24V

transformer, or may cause other safety control

damage or failure.

Start-Up

1. Turn power on.

2. Turn on the heater, wait approximately 15 seconds

after the blower starts, the igniter should start to

glow (observable through the observation port

located at the front, bottom of the heater). Look

into the sight glass located at the bottom of the

front panel to check igniter operation. Gas valve

should open in 45-60 seconds.

3. The heater ignites at 50% of full rate (as indicated

on the LCD display of the temperature control

located in the upper right of the front panel).

4. If the burner fails to light on the first trial, it will try

for ignition up to three times before going into lock-

out with the standard ignition module. If the heater

is equipped with the optional single-try ignition

module, it will go into lockout.

5. Wait until the controller indicates 100% on the fir-

ing rate display screen (approximately 30

seconds).

Blower Check

1. Check blower suction using the manometer

attached to the fan pressure switch tee, with the

heater firing at 100% input. The reading should be

as noted in Table T for both natural and propane

gas.

GAS

TO BURNER

A

B

C

D

Fig. 47: Gas Pressure Measurement Locations

m

um supply pressure for propane gas is 4.0 in.

WC, recommended supply is 11.0 in. WC (dynam-

ic readings, full fire input).

3

. If the gas pressure is greater than 14.0 in. WC,

turn off the main gas shut-off valve, upstream of

t

he heater.

NOTE: The values in Tables T, U and V represent

the conditions when the heater is at full firing rate at

sea level.

NOTE: Most commercially available amp probes

are not accurate enough and/or are not shielded well

enough to read accurately in the heater

environment. Blower amp draw readings are for

reference only.

WARNING: Do not turn on gas at this time.

NOTE: Pressure and combustion data are provided

with the heater.