28

The vent must be installed to prevent flue gas leakage.

Care must be taken during assembly to ensure that all

joints are sealed properly and are airtight. The vent

must be installed to prevent the potential accumulation

of condensate in the vent pipes. It is required that:

1. The vent must be installed with a condensate

drain located in proximity to the heater as directed

by the vent manufacturer.

2. The vent must be installed with a slight upward

slope of not less than 1/4 inch per foot of horizon-

tal run to the vent terminal.

3. The vent must be insulated through the length of

the horizontal run.

Termination

The flue direct vent cap MUST be mounted on the ex-

terior of the building. The direct vent cap cannot be

installed in a well or below grade. The direct vent cap

must be installed at least 1 ft above ground level and

above normal snow levels. The Raypak-approved

stainless steel flue direct vent cap must be used (sales

order option D-15). The vent terminal must be located

NO CLOSER than 12” off the wall.

** Subtract 10 ft per elbow. Max. 4 elbows.

t

Adapters supplied by others.

Table N: Category IV Horizontal Vent & Horizontal Direct Vent

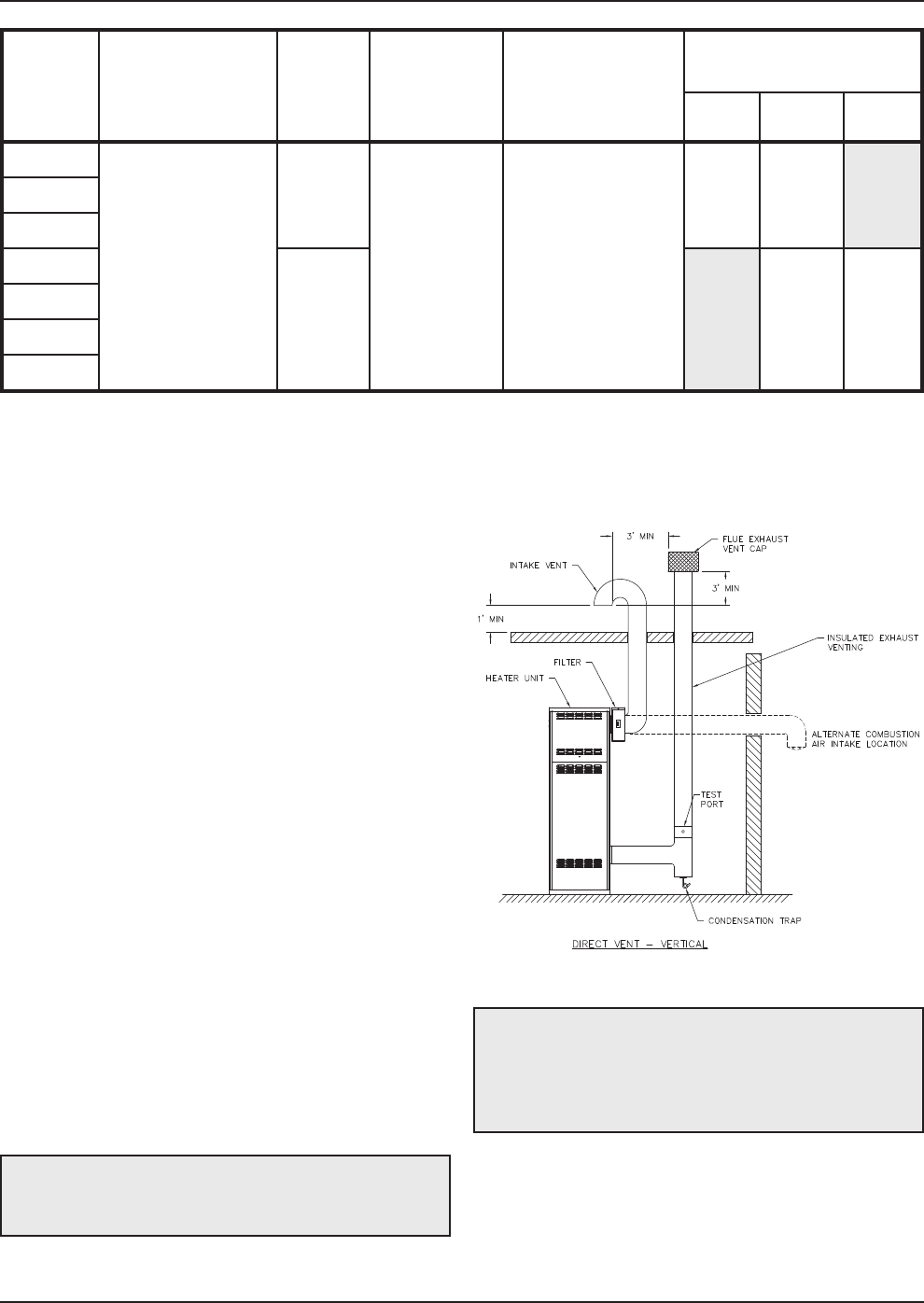

Direct Vent—Vertical

Installation

These installations utilize the heater-mounted blower

to draw combustion air from outdoors and vent com-

bustion products to the outdoors.

WARNING: No substitutions of flue pipe or vent

cap material are allowed. Such substitutions would

jeopardize the safety and health of inhabitants.

CAUTION: This venting system requires the

installation of a condensate drain in the vent piping

per the vent manufacturer’s instructions. Failure to

install a condensate drain in the venting system will

void all warranties on this heater.

Fig. 28: Direct Vent - Vertical

Model

No.

C

ertified

Vent

M

aterial

V

ent

Size

(

in.)

Maximum

Horizontal

Vent Length

(ft)

C

ombustion Air

Intake Pipe

M

aterial

Air Inlet

Max. Length** (ft)

6

” Ø

8

” Ø

1

0” Ø

503

Category IV

(AL29-4C)

6

75

Galvanized Steel,

PVC,

ABS,

CPVC

45

1

00

t

753

1003

1253

8 45

85

t

1503

1753

2003