32

To check the heat anticipator setting either:

1. Add the current draw of the system compo-

nents; or

2. Measure the current fl ow on the thermostat

R-W circuit after the circulating blower motor

has started.

Set the heat anticipator according to the ther-

mostat manufacturer’s instructions for heat

anticipator settings.

START-UP AND ADJUSTMENTS

Prior to start-up, verify that:

1. The line voltage power leads are securely

connected, that the polarity of the con-

nections is correct, and that the furnace is

properly grounded.

2. The thermostat wires (R, W, Y, and G) are

securely connected to the correct leads on

the terminal strip of the circuit board.

3. The gas line service pressure does not

exceed 10.0 in. water column (0.36 psig),

and is not less than 4.5 in. water column

(0.16 psig) for natural gas. For LP gas the

line service pressure must not exceed 14

in. water column (0.51 psig), and must not

be less than 11.0 in. W.C. (0.40 psig).

4. The roll-out and vent safety manual reset

switches are closed. If necessary, press the

red button to reset a switch. See Figure 30

for location. DO NOT install a jumper wire

across a switch to defeat its function. If a

switch reopens on start-up, DO NOT reset

the switch without identifying and correcting

the fault condition which caused the switch

to trip.

5. The blower door is in place, closing the door

switch in the line voltage circuit.

6. The gas line has been purged and all con-

nections are leak tight.

Start-Up Procedure

1. Set the thermostat to the lowest setting.

2. Close the disconnect(s) to provide line volt-

age to the furnace.

3. Follow the procedures given on the operating

instructions label attached to the furnace.

4. Set the thermostat above room temperature

and verify the sequence of operation. (See

the SEQUENCE OF OPERATION.)

5. After the furnace has run for approximately

fi ve minutes, set the thermostat below room

temperature and verify steps (9) through

(11) of the SEQUENCE OF OPERATION.

Verifying and Adjusting

Firing Rate

The fi ring rate must be verifi ed for each installa-

tion to prevent over-fi ring the furnace.

NOTE: The fi ring rate must not exceed the rate

shown on the furnace rating plate. At altitudes

above 2000 ft. the fi ring rate must be adjusted

as described in the high altitude section.

Use the following procedure to determine the

fi ring rate:

1. Shut off all other gas fi red appliances.

2. Start the furnace and allow it to run for at

least three minutes.

3. Measure the time (in seconds) required for

the gas meter to complete one revolution.

4. Convert the time per revolution to cubic feet

of gas per hour using Table 13.

5. Multiply the gas fl ow rate in cubic feet per

hour by the heating value of the gas in Btu

per cubic foot to obtain the fi ring rate in Btuh.

Example:

• Time for 1 revolution of a gas meter with

a 1 cubic foot dial = 40 seconds.

• From Table 9 read 90 cubic feet per hour

of gas.

• Heating value of the gas (obtained

from gas supplier) = 1040 Btu per cubic

foot.

• Firing rate = 1040 x 90 = 93,600 Btuh.

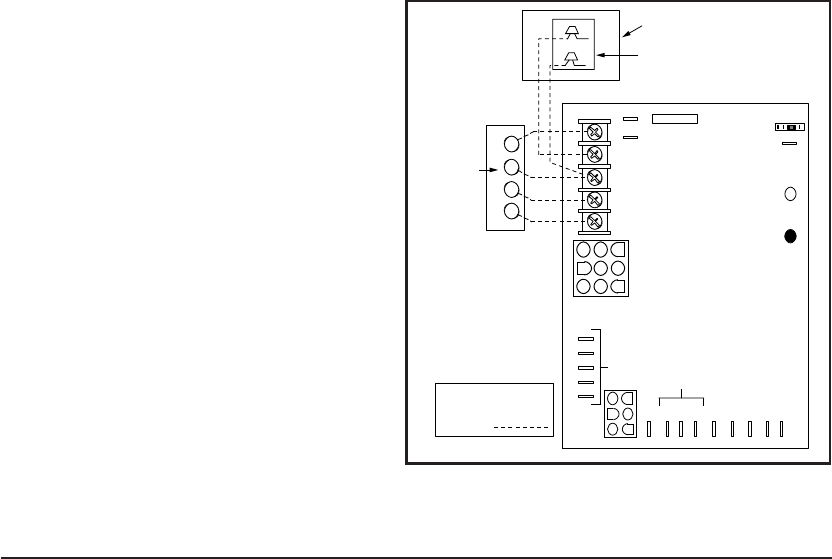

Figure 27. Low Voltage Field,

Four-wire Heating/Cooling Applications

R C Y G W

A/C Condensing Unit

Condensing Unit

Control Box

Room

Thermostat

Flame Signal Light

(Yellow)

Status Light

(Red)

60

90

120

180

Blower Off

Timing

TWIN

3 Amp

Fuse

COM

24 V

HUM

Neutrals

Low Voltage

Connections

41

52

63

7

8

9

4

5

6

1

2

3

EAC

HUM

M1

M2

M3

HEAT

L1

XFMR

Unused Motor Leads

EAC

R Y G W

Connect

R & W

For

Heating

Only

FIELD WIRING

NOTE: The "Y"

terminal on the

UTEC control board

must be connected

to the thermostat

for proper cooling

mode operation.

COOL