17

ENGLISH

A Valve stem

[Fully closed at the factory, when connecting the piping, when evacuating,

and when charging additional refrigerant. Open fully after the operations

above are completed.]

B Stopper pin [Prevents the valve stem from turning 90° or more.]

C Packing (accessory)

D Distributer (gas) (option)

Mount packing (accessory) securely to the valve flange so that gas does

not leak. (screw tightening torque is 43 N·m (430 kg·cm). Apply a coat of

refrigerating machine oil to both surfaces of the packing.

D’ Connecting pipe (accessory)

[Use packing and securely install this pipe to the valve flange so that gas

leakage will not occur. (tightening torque: 25 N·m (250 kg·cm)) Coat both

surfaces of the packing with refrigerator oil.]

E Open (operate slowly)

F Cap, copper packing

[Remove the cap and operate the valve stem. Always reinstall the cap after

operation is completed. (valve stem cap tightening torque: 25 N·m

(250 kg·cm) or more)]

G Service port

[Use this port to evacuate the refrigerant piping and add an additional charge

at the site.

Open and close the port using a double-ended wrench.

Always reinstall the cap after operation is completed. (service port cap

tightening torque: 14 N·m (140 kg·cm) or more)]

H Flare nut

[Tightening torque: 80 N·m (800 kg·cm) ··· liquid, 55 N·m (550 kg·cm) ··· oil

blance

Loosen and tighten this nut using a double-ended wrench.

Coat the flare contact surface with refrigerator oil.]

H’ Flare nut

Tightening torque is 55 N·m (550 kg·cm). Use a double spanner to open

and close. Apply a coat of refrigerating machine oil to the flare bonding

surface.

I ø38.1 (PUHY-600YSMC)

ø44.5 (PUHY-650/700/750YSMC)

J Field piping

[Braze to the connecting pipe. (when brazing, use unoxidized brazing.)]

Appropriate tightening torque by torque wrench

Copper pipe external dia. (mm) Tightening torque (N·m) / (kg·cm)

ø6.35 14 to 18 / 140 to 180

ø9.52 35 to 42 / 350 to 420

ø12.7 50 to 57.5 / 500 to 575

ø15.88 75 to 80 / 750 to 800

ø19.05 100 to 140 / 1000 to 1400

Tightening angle standard

Pipe diameter (mm) Tightening angle (°)

ø6.35, ø9.52 60 to 90

ø12.7, ø15.88 30 to 60

ø19.05 20 to 35

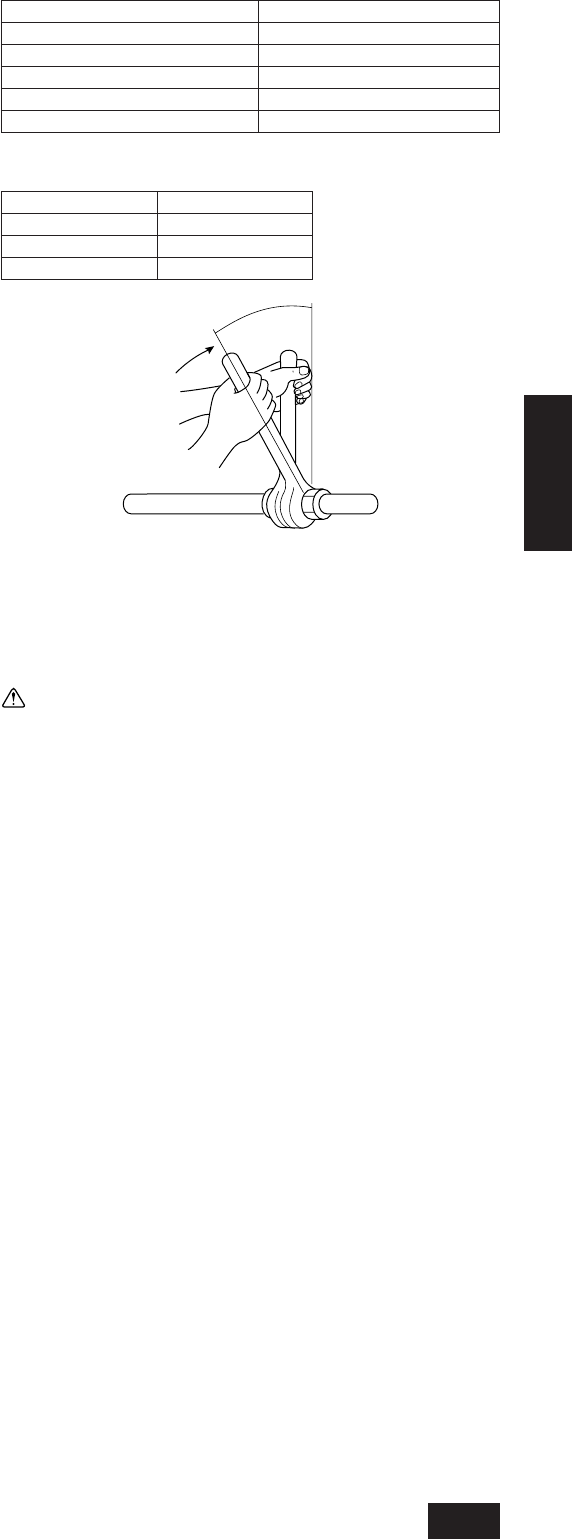

Note:

If a torque wrench is not available, use the following method as a

standard

When you tighten the flare nut with a wrench, you will reach a point

where the tightening torque will abrupt increase. Turn the flare nut

beyond this point by the angle shown in the table above.

Caution:

Always remove the connecting pipe from the ball valve and braze it

outside the unit.

- Brazing the connecting pipe while it is installed will heat the ball valve

and cause trouble or gas leakage. The piping, etc. inside the unit may

also be burned.