76 Ceiling & Floor, Ceiling Suspended (50Hz, R22)

15. Installation

Check

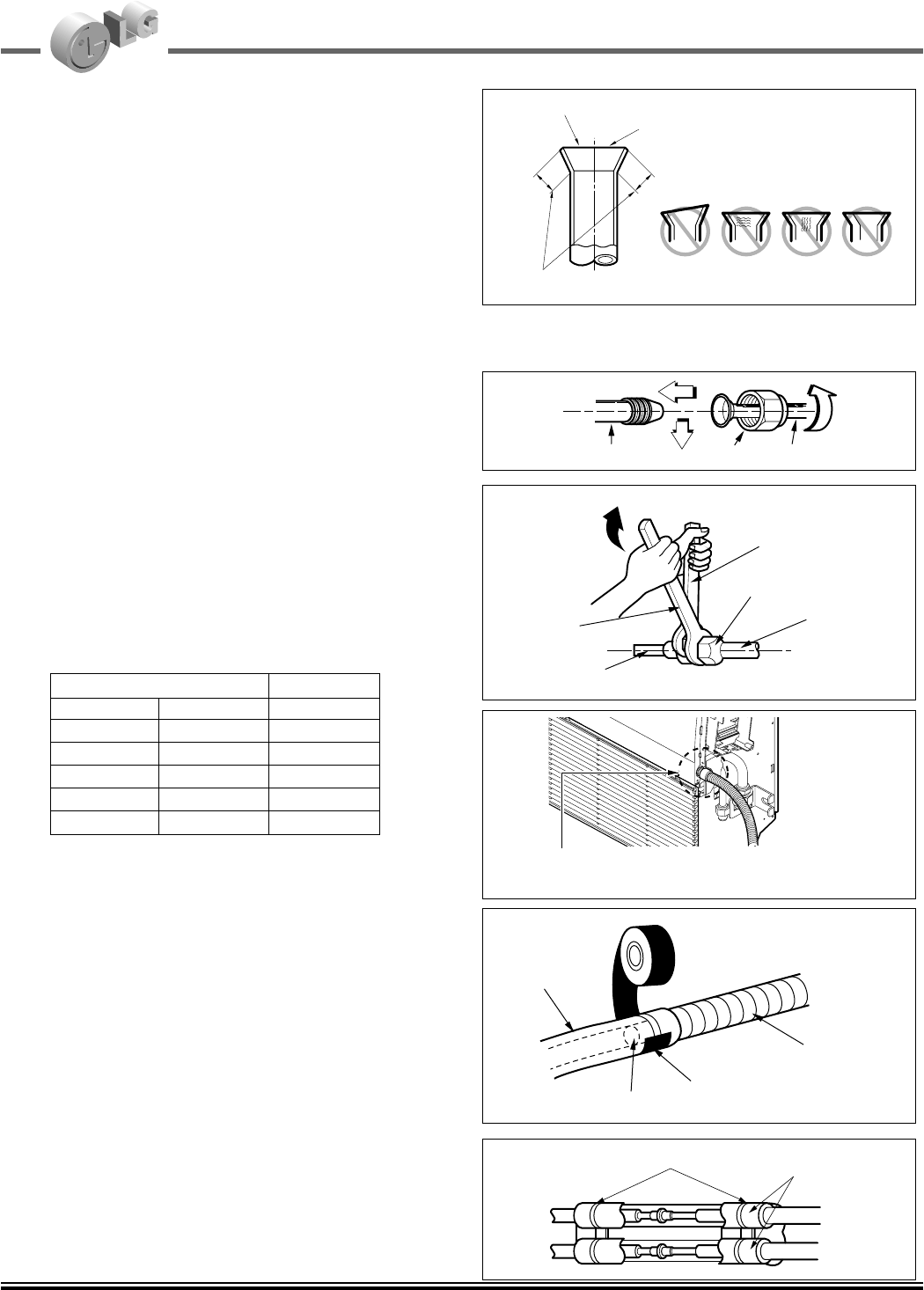

1. Compare the flared work with the figure by.

2. If a flared section is defective, cut it off and do flaring

work again.

4) Connecting of Piping - Indoor

1. Prepare the indoor unit piping and drain hose for

installation thought the wall.

2. Align the center of the liquid side pipe.

3. Sufficiently tight the flare nut of the liquid side pipe

with hands.

4. Tight the flare nut with two spanner, as shown.

5. Align the center of gas side pipes.

6. Sufficiently tight the flare nut of the gas side pipe with

hands.

7. Tight the flare nut with two spanner as shown.

8. If drain pipe need to be extended at the indoor side

attach the drain pipe with indoor unit drain hose as

shown in fig.

Wrap the insulation material around con-

nection portion

9. Overlap the connection connecting pipe insulation

material and the indoor pipe insulation martial. Bind

them together with the vinyl tape. So that here may

not be any gap.

Inclined

Inside is shiny without scratches

Smooth all round

Even length

all round

Surface

damaged

Cracked Uneven

thickness

= Improper flaring =

mm inch kg

.

m

Ø6.35 1/4 1.8

Ø9.52 3/8 4.2

Ø12.7 1/2 5.5

Ø15.88 5/8 6.6

Ø19.05 3/4 6.6

Outside diameter Torque

Indoor unit tubing Flare nut Pipes

Wrench

Indoor unit tubing

Connection pipe

Flare nut

Open-end wrench (fixed)

Vinyl tape

Adhesive

Drain hose

Indoor unit drain hose

(narrow)

Plastic bands

Insulation material

❈ Seal properly the joint of drain hole and drain pipe with

adhesive tape to prevent leakage of water drops.