22

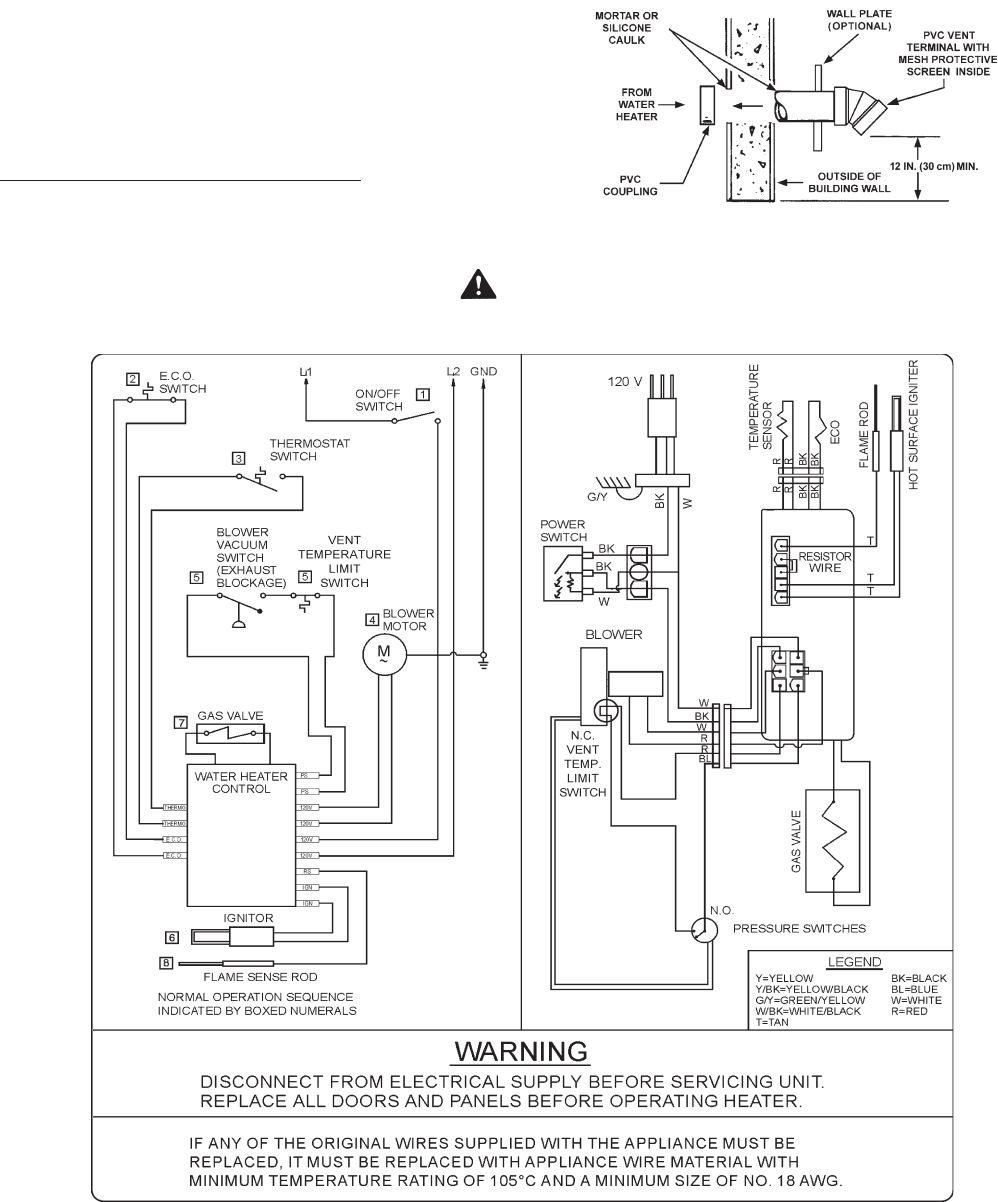

CAUTION

LABEL ALL WIRES PRIOR TO DISCONNECTION WHEN SERVICING CONTROLS. WIRING ERRORS CAN CAUSE IMPROPER AND

DANGEROUS OPERATION. VERIFY PROPER OPERATION AFTER SERVICING.

POWER VENT WIRING SCHEMATIC - FIGURE 19.

Align holes by drilling a hole through center of the template

from the inside through to the outside. The template can now

be positioned on the outside wall using the drilled hole as a

centering point for the template.

3. A) MASONRY SIDE WALLS

Chisel an opening approximately one half inch (1.3 cm) larger

than the marked circle.

B) WOODEN SIDE WALLS

Drill a pilot hole approximately one quarter inch (0.64 cm) outside

of the marked circle. This pilot hole is used as a starting point

for a saws-all or sabre saw blade. Cut around the marked circle

staying approximately one quarter inch (0.64 cm) outside of the

line. (This will allow the vent to easily slide through the opening.

The resulting gap will be covered up by the Vent Terminal cover

plate.) Repeat this step on inside wall if necessary.

SEQUENCE OF INSTALLATIONS, FIGURE 18

Cut a length of PVC pipe about 3.5 inches (8.9 cm) longer than wall

thickness at the opening. Glue vent terminal to this section of pipe.

Slide the wall plate over the pipe to stop against the vent terminal.

Place a bead of caulking (not supplied) around the gap between the

pipeandcoverplate.Applyenoughtollsomeofthegapbetween

the pipe and wall. Place some of the caulking on the back of the plate

to hold it against the wall after installation. If the vent pipe is installed

up to the wall, with a coupling on the end against the wall opening,

the pipe with the vent terminal can be prepared for gluing before

inserting through the wall. Slide the pipe through the wall and insert

into the coupling on the other side of the wall, making sure that the

vent terminal ends up pointed in the correct position, see Figure 18.

VENT TERMINATION - FIGURE 18.