15

THERMAL EXPANSION

As water is heated, it expands (thermal expansion). In a closed system

the volume of water will grow when it is heated. As the volume of water

grows there will be a corresponding increase in water pressure due to

thermal expansion. Thermal expansion can cause premature tank failure

(leakage). This type of failure is not covered under the limited warranty.

Thermal expansion can also cause intermittent Temperature-Pressure

Relief Valve operation: water discharged from valve due to excessive

pressure build up. This condition is not covered under the limited warranty.

The Temperature-Pressure Relief Valve is not intended for constant relief

of thermal expansion.

A properly sized thermal expansion tank must be installed on all

closed systems to control the harmful effects of thermal expansion.

Contact a local plumbing service agency to have a thermal expansion

tank installed.

NOTE: To protect against untimely corrosion of hot and cold

water ttings, it is strongly recommended that di-electric unions

or couplings be installed on this water heater when connected

to copper pipe.

All gas piping must comply with local codes and ordinances or with

the Natural Gas and Propane Installation Code (CAN/CSA B149.1).

Copperandbrasstubingandttings(excepttinlinedcoppertubing)

should not be used.

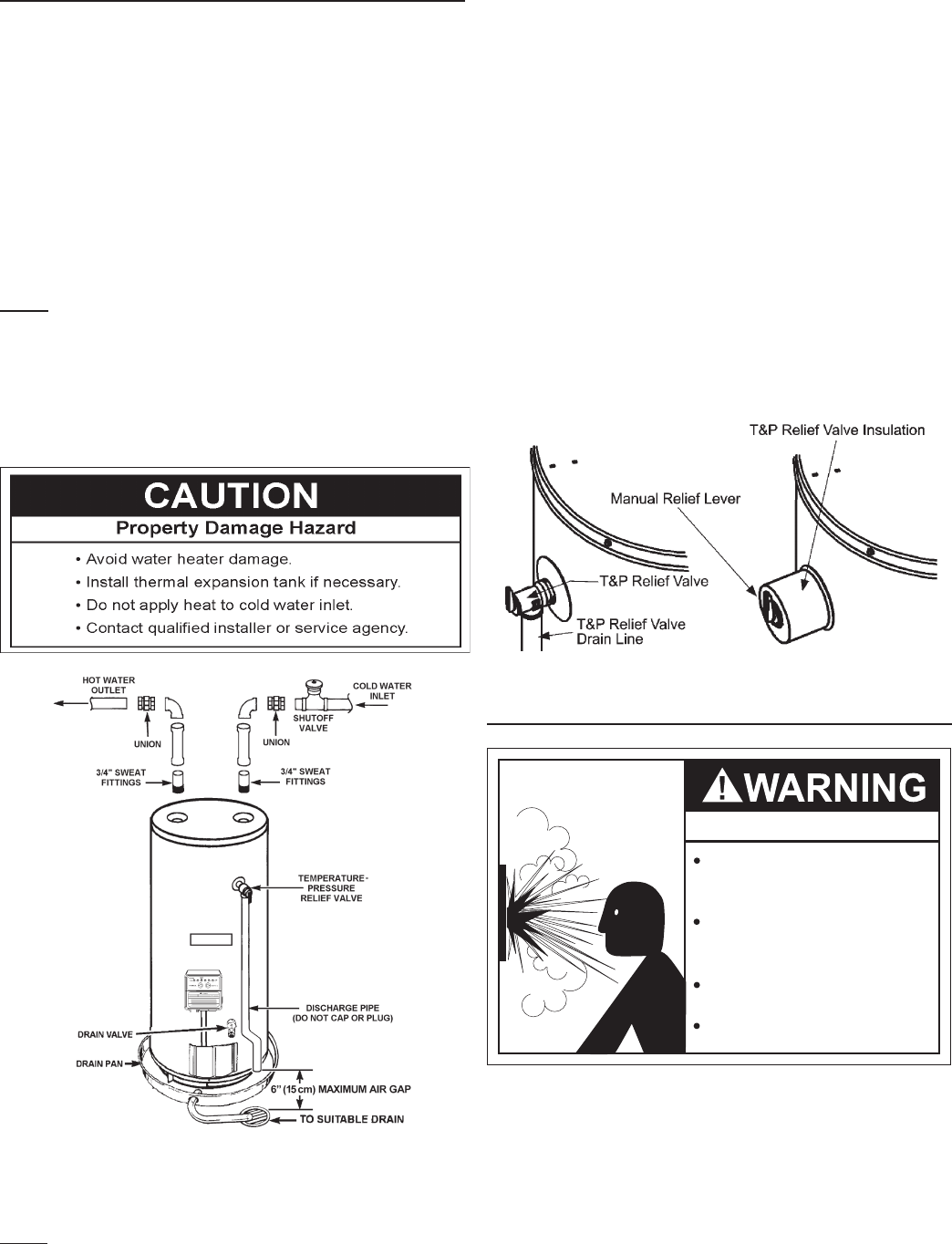

FIGURE 10.

Figure 10 shows typical attachment of water piping to the water heater.

The water heater is equipped with 3/4 inch NPT water connections.

NOTE: If using copper tubing, solder tubing to an adapter before

attaching the adapter to the water heater connections. Do not

solder the water lines directly to the water heater connections.

It will harm the dip tube and damage the tank.

T & P Valve and Pipe Insulation

1. Locate the temperature and pressure relief valve on the water

heater (also known as a T&P relief valve). See Figure 11.

2. Locate the slit running the length of the T&P relief valve insulation.

3.Spread the slit open and t the insulation over the T&P relief

valve. See Figure 11. Apply gentle pressure to the insulation to

ensure that it is fully seated on the T&P Relief Valve. Once seated,

secure the insulation with duct tape, electrical tape, or equivalent.

IMPORTANT: The insulation and tape must not block the discharge

opening or hinder access to the manual relief lever (Figure 11).

Ensure a discharge pipe is installed into the T&P valve discharge

opening per the instructions in this manual.

4. Locate the hot water (outlet) & cold water (inlet) pipes to the water

heater.

5. Locate the slit running the length of a section of pipe insulation.

6. Spread the slit open and slip the insulation over the cold water

(inlet) pipe. Apply gentle pressure along the length of the insulation

to ensure that it is fully seated around the pipe. Also, ensure that the

baseoftheinsulationisushwiththewaterheater.Onceseated,

secure the insulation with duct tape, electrical tape, or equivalent.

7. Repeat steps 5 and 6 for the hot water (outlet) pipe.

8. Add additional sections of pipe insulation as needed.

FIGURE 11.

TEMPERATURE-PRESSURE RELIEF VALVE

Explosion Hazard

Temperature-Pressure Relief Valve

must comply with ANSI Z21.22-

CSA 4.4 and ASME code.

Properly sized Temperature-Pressure

Relief Valve must be installed in

opening provided.

Can result in overheating and

excessive tank pressure.

Can cause serious injury or death.

Thiswaterheaterisprovidedwithaproperlyrated/sizedandcertied

combination Temperature-Pressure Relief Valve (T&P valve) by the

manufacturer.Thevalveiscertiedbyanationallyrecognizedtesting

laboratory that maintains periodic inspection of production of listed

equipment of materials as meeting the requirements for Relief Valves

forHotWaterSupplySystems,ANSIZ21.22•CSA4.4,andthecode

requirements of ASME.

If replaced, the new T&P valve must meet the requirements of local

codes, but not less than a combination Temperature-Pressure Relief

Valverated/sizedandcertiedasindicatedintheaboveparagraph.

The new valve must be marked with a maximum set pressure not to