INSTALLATION, GENERAL

The Bayvue DV installation must ensure adequate combustion air and ventilation air is available for proper

stove operation. Refer to the venting section for further combustion air requirements. Installation must

conform to local codes and gas supplier restrictions. In the absence of local codes, an installation must

conform to the current National Fuel Gas Code which at the writing of this manual is ANSI Z223.1

(reference NFPA-54 for natural gas or reference NFPA-58 for propane products). In Canada, an

installation must conform to CAN/CGA-B149 code.

This appliance must be electrically connected and grounded in accordance with local codes, or in the

absence of local codes, with the current NFPA 70 National Electric Code or in Canada, with CSA C22.1

Canadian Electrical Code.

IT IS IMPERATIVE THAT THIS APPLICANCE’S CONTROL COMPARTMENT, BURNER, AND

CIRCULATING AIR PASSAGE WAYS ARE KEPT CLEAN AND CLEAR OF OBSTRUCTIONS.

ALWAYS PROVIDE FOR ADEQUATE COMBUSTION AIR AND ENSURE PROPER OPERATION

AT ALL TIMES. PROVIDE ADEQUATE CLEARANCES AROUND AIR OPENINGS AND

NECESSARY ACCESSIBILITY FOR ROUTINE OPERATION AND SERVICE. NEVER OBSTRUCT

ANY OPENINGS ON THIS APPLIANCE OR NEVER OBSTRUCT THE DIRECT VENT

TERMINATION ON THE EXTERIOR OF THE BUILDING.

MINIMUM CLEARANCES TO COMBUSTIBLES MUST BE MAINTAINED DURING

INSTALLATION. THE HEATER MUST HAVE ADEQUATE SPACE FOR PROPER OPERATION

AND SERVICING. MAINTAIN MINIMUM CLEARANCES AND VENT/AIR INTAKE PIPE

CLEARANCES.

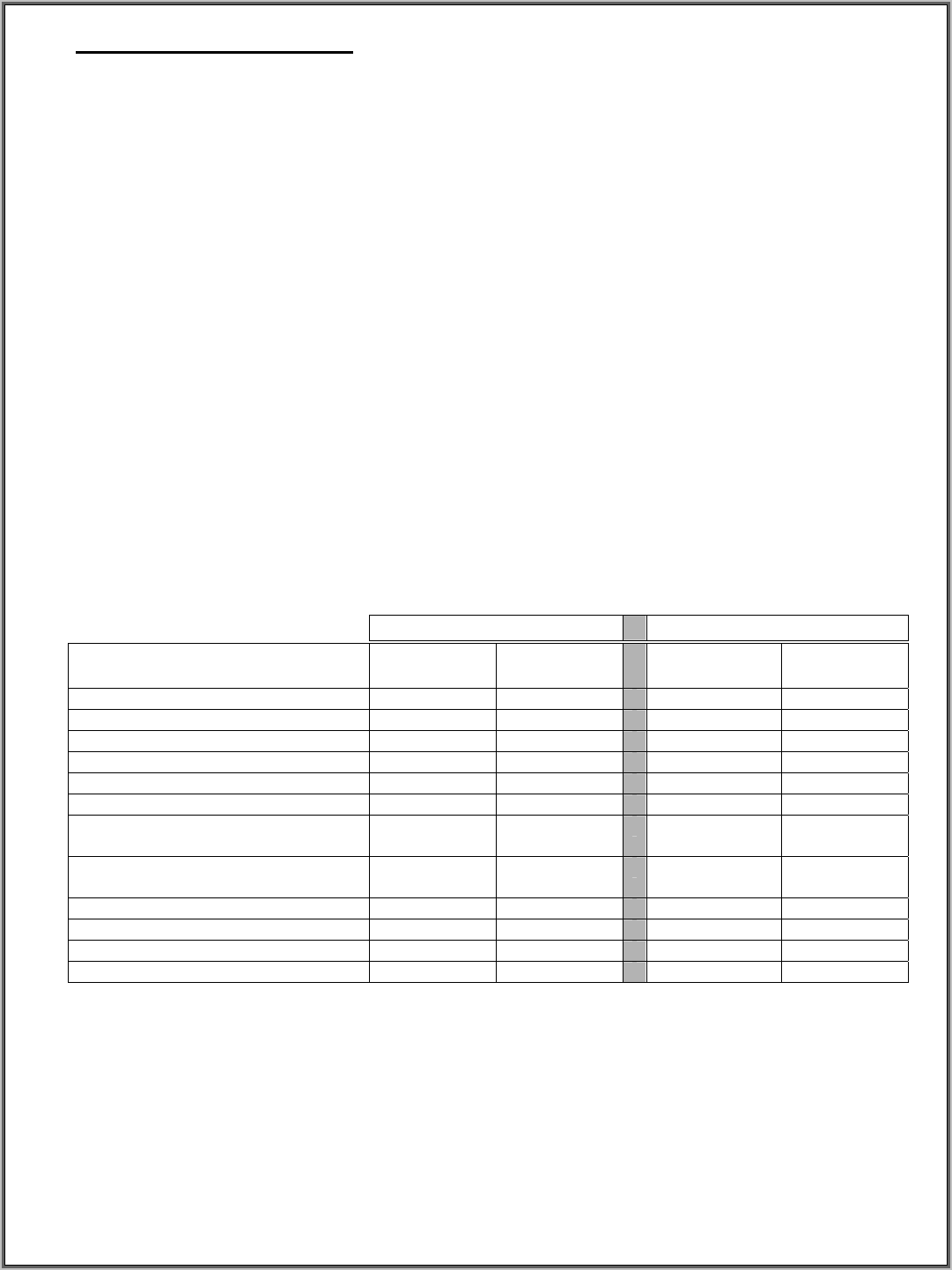

TABLE 1: BAYVUE DV SPECIFICATIONS

BAYVUE DV-46

BAYVUE DV-30

NATURAL

GAS

PROPANE

NATURAL

GAS

PROPANE

Altitude 0 - 4500’ 0 - 4500’ 0 - 4500’ 0 - 4500’

Manifold pressure 3.5” W.C. 10” W.C. 3.5” W.C. 10” W.C.

Minimum Inlet Gas Pressure 4.5” W.C. 11” W.C. 4.5” W.C. 11” W.C.

Maximum. Inlet Gas Pressure 7.0” W.C. 14.0” W.C. 7.0” W.C. 14.0” W.C.

BTU Input Rating (High) 46,000 46,000 BTUH 32,000 30,000 BTUH

BTU Input Rating (Low) 29,000 34,500 BTUH 21,000 21,500 BTUH

*Efficiency with fan (steady

state)

35,700 36,800 BTUH 24,000 23,100 BTUH

*Efficiency no fan (steady

state)

37,200 39,100 BTUH 22,800 22,000 BTUH

*A.F.U.E. 68.77% 70.67% 60.19% 62.22%

Front Burner Orifice 55 DMS 69 DMS 57 DMS 70 DMS

Middle Burner Orifice 45 DMS 55 DMS 50 DMS 59 DMS

Rear Burner Orifice 40 DMS 53 DMS 45 DMS 55 DMS

*ANSI standards are SAFETY STANDARDS not PERFORMANCE STANDARDS. A.F.U.E.

(efficiency standards) and efficiency test protocol are established by the U. S. Department of Energy.

PRESSURE TESTING

Version 1.0h

5

This appliance MUST BE isolated from the gas supply piping system during any pressure testing of the

gas supply piping system at test pressures equal to or less than ½ pounds per square inch gauge (psig) (3.5

kPa or 14” W.C.) Isolate the appliance by closing the manual shutoff valve during pressure testing.

Failure to isolate the appliance will cause damage and can require replacement of the SIT 820 NOVA mV

gas control valve. If test pressures will be in excess of ½ psig, then the SIT 820 NOVA mV gas control

valve must be disconnected from the gas supply line. Refer to FIGURE 27 for SIT 820 NOVA mV valve

information.