52C,P

SERIES

14

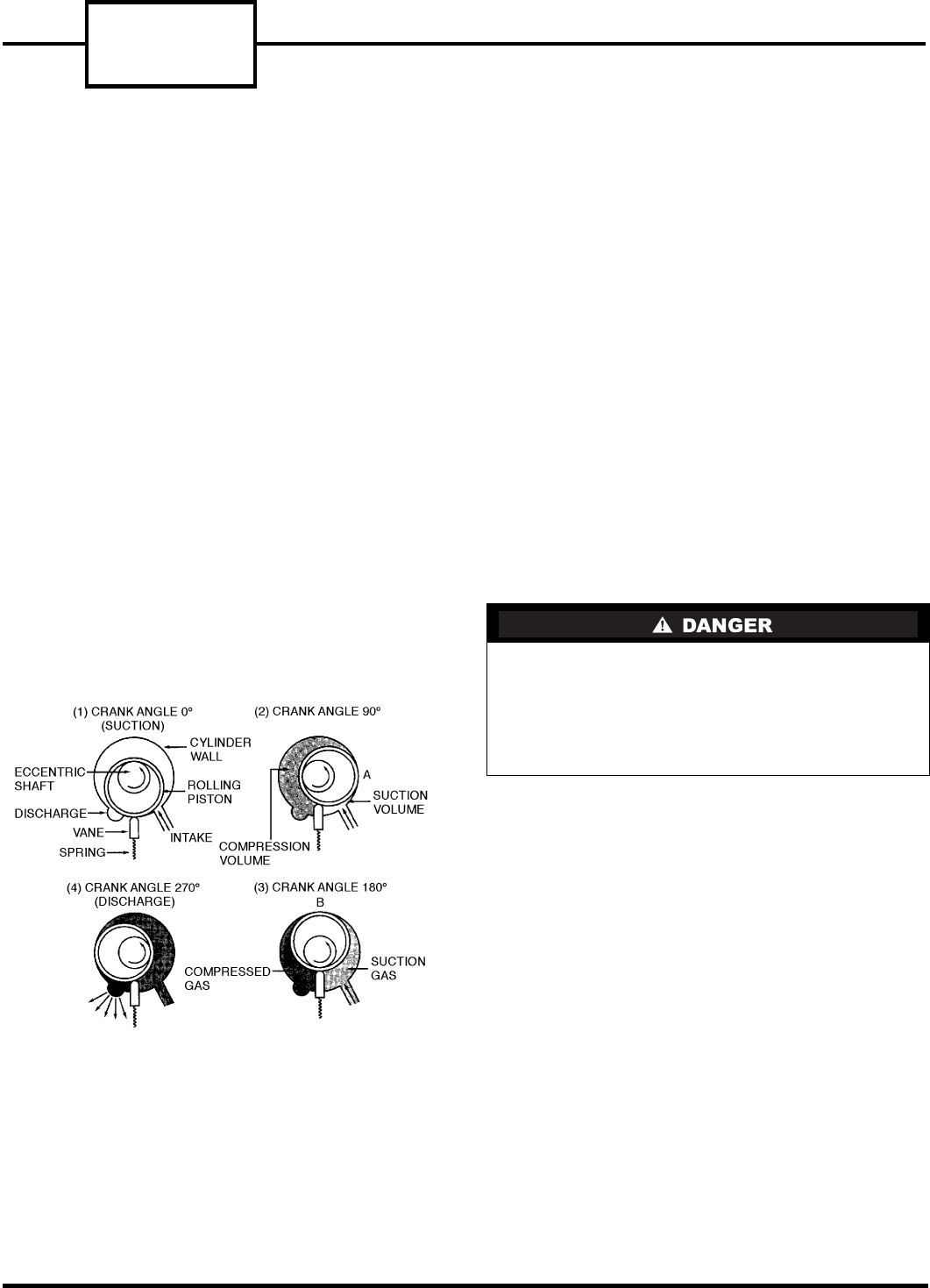

The rotary compression process (Figure 28), starts at

top dead center as shown in (1). Suction gas flows

through the suction inlet and into the cylinder area.

As the shaft rotates through 90 degrees, the rolling

piston moves to position A as shown in (2). The suction

volume is now the area defined by point A and the tip

of the vane. Gas in the remaining volume has been

compressed above suction pressure. After another

90 degrees of shaft rotation, the rolling piston has

moved to position B as shown in (3). Both the com-

pressed gas and suction gas volumes are now equal.

Another 90 degrees of shaft rotation is shown in (4).

Compressed gas has reached a pressure sufficient to

open the discharge valve, and flows from the cylinder

into the compressor shell. After another 90 degrees of

shaft rotation, the entire process begins again. Contin-

uous suction and discharge allows for a smooth com-

pression process.

The rolling piston is not in actual contact with the cyl-

inder wall, vane, or bearing faces. Hydrodynamic seal-

ing prevents leakage from the compressed gas volume

to the suction volume via these paths. Precise control

of machining tolerances, surfaces, finishes, and assem-

bly clearances is critical to achieve high efficiency per-

formance. In addition, the line contact between the

vane tip and the rolling piston requires careful selec-

tion and control of materials to provide wear resis-

tance and reliable long-term operation.

COMPRESSOR TROUBLESHOOTING

Refer to Figure 29 for a basic compressor troubleshoot-

ing chart.

BASIC HERMETIC COMPRESSOR

ELECTRICAL MEASUREMENTS

There are 2 basic electrical tests for hermetic compres-

sors that will determine the electrical state of the

motor. The first test requires checking the electrical

resistance of each of the electrical motor windings. The

second test requires checking the electrical resistance

of each of the electrical motor windings to ground.

These tests may be accomplished by performing the

following steps:

1. DISCONNECT ALL POWER TO THE UNIT.

2. Remove the unit chassis from the sleeve as

detailed in the UNIT DISASSEMBLY section.

3. Open the control box as detailed in the UNIT

DISASSEMBLY section, then locate, label, and

remove the 3 compressor wires from the following

locations: the RUN wire (BLACK) from the capac-

itor, the START wire (BLUE) from the capacitor.

The third wire, COMMON wire (YELLOW) may

be connected to one of the following locations: for

PC units the wire is on the indoor thermostat,

for CE, PE Remote Control Units the wire is

on the RC Control Board, for all other CE, PE

Units the wire is located on the rotary selector

switch. For ALL CQ, PQ Units the wire is on the

outdoor frost thermostat.

4. Perform a shorted/open windings test to measure

the resistance between the windings of the com-

pressor motor. Use a volt-ohmmeter set to the

lowest ohm reading level then read and record the

resistance between the RUN and START, START

and COMMON, and RUN and COMMON wires.

See Figure 30. The typical resistance readings will

be about 4, 3, and 1 ohms respectively. The

smaller values should add to equal the larger

value. If this is not true then the compressor is

likely shorted winding to winding.

NOTE: The rotary compressor has the compressor

overload located under the terminal cover. If the over-

load is open it can show ohm readings that are infinite.

The unit should be off for at least an hour to give this

overload time to reset if it is open.

For compressors that are known to be dam-

aged: Remove refrigerant prior to disconnecting

compressor wires. Damaged hermetic compressor

terminals may become loose and eject from the com-

pressor. Wear safety glasses and keep your face

away from the area above the terminals when

removing compressor wires.

FIGURE 28 — ROTARY COMPRESSOR

COMPRESSION PROCESS