Features with sensor control of unit with computer access

are:

• 365 day timeclock with backup (supports minute, hour,

day of week, date, month, and year)

• daylight savings time function

• occupancy control with 8 periods for unit operation

• holiday table containing up to 18 holiday schedules

• ability to initiate timed override from T-55 or T-56 sensors

• ability to use multiple space temperature sensors to aver-

age the space temperature

• supply air temperature reset for the supply air temperature

set point

• temperature compensated start to calculate early start times

before occupancy

• access to the Display, Maintenance, Configuration, Serv-

ice, and Set Point data table through network software

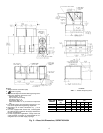

When the unit is equipped with a field-supplied space tem-

perature sensor and a remote contact closure (remote start/

stop) on the base control board, the occupied default set points

will monitor unit operation. The occupied default set points

are 78 F cooling and 68 F heating (if electric heat is in-

stalled). See Fig. 11 for remote start/stop wiring.

NOTE: For units which have not had the base unit control

board accessed via software to set an occupancy schedule,

the remote start/stop closure will allow the unit to operate in

the pre-configured occupied default set points (based on return-

air temperature) of 78 F cooling and 68 F heating. Without

this feature, the unit will control to the unoccupied default

set points of 90 F cooling and 55 F heating (if electric heat

is installed).

An electronic expansion board may be field-installed to

provide the following features:

• control of modulating economizer damper to maintain

indoor air quality (IAQ) when outdoor conditions are

suitable

• provide discrete inputs for fan status, filter status, field-

applied status, and demand limit

• provide an output for the external alarm light indicator

When the unit is connected to the CCN (Carrier Comfort

Network), the following expansion board features can be

utilized.

• perform Demand Limit functions based on CCN loadshed

commands or the state of the discrete input

• alarm monitoring of all key parameters

• CCN protocol

• provides power exhaust fire outputs for direct control of

modulated power exhaust stages during fire or smoke modes

• smoke control modes including evacuation, smoke purge,

pressurization, and fire shutdown (modulating power ex-

haust required)

• provides CCN IAQ participation

See Carrier TEMP or VVT (Variable Volume and Tem-

perature) literature for complete TEMP (single zone) or VVT

(multi-zone) application information.

Features with Sensor Control of Unit (Network Applica-

tions) — The base control board provides, as standard, a con-

nection for use with a Carrier VVT system and can also be

integrated into a Carrier Comfort Network.

When the unit is accessed via a PC equipped with Com-

fort Works, Building Supervisor, or Service Tool, the fol-

lowing features can be accessed:

• on-board timeclock can be programmed

• occupancy schedules can be programmed

• unit set points can be changed

• alarms can be monitored

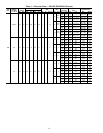

This access is available on the base control board via a

RJ-11 phone jack or a 3-wire connection to the communi-

cation bus. See Fig. 12. The timeclock has a 10-hour minimum

back-up time to provide for unit power off for servicing unit

or during unexpected power outages. For complete Carrier

Comfort System (CCS) or Carrier Comfort Network (CCN)

features and benefits, refer to the product literature.

VARIABLE AIR VOLUME (VAV) APPLICATIONS

Features with Stand-Alone Applications — A VAV unit is

capable of providing unoccupied cooling controlling to a

90 F return-air temperature utilizing the factory-supplied return-

air thermistor located below the return-air damper in the return-

air section for unit control. The unit will provide unoccupied

heating (if electric heat is installed) controlling to a 55 F

return-air temperature. Also provided is a morning warm-up

which is initiated by the Occupied mode (if electric heat is

installed) and continues until the return-air temperature rises

to 68 F. The unit will provide occupied cooling with a de-

fault temperature of 55 F for the supply air. The supply-air

temperature is measured by the supply-air thermistor, lo-

cated in the indoor fan compartment.

Standard features of a VAV unit with a remote start/stop

switch are:

• control of an outdoor condenser fan based upon outdoor

air temperature

• control of modulating economizer to provide free cooling

when outdoor conditions are suitable, using supply air tem-

perature as a set point

• support of remote occupied/unoccupied input to start or

stop the unit

• provide power exhaust output to an external power ex-

haust controller

• support supply air temperature reset to offset supply air

set point

• support a field test for field check out

• support linkage to DAV systems

• cooling capacity control of 6 stages plus economizer with

compressors and unloaders to maintain supply air tem-

perature set point during occupied periods

• control of one stage of heat to maintain supply air tem-

perature at supply air set point during occupied periods

• provide a variable frequency drive high voltage relay out-

put to enable VFD

• control of heat interlock relay

With the addition of a remote start/stop switch heating or

cooling is enabled during unoccupied periods as required to

maintain space temperature to within unoccupied set points.

NOTE: On units running Version 1.0 of the Unit Control Software, the remote

start/stop switch is connected to R andY1. On units running Version 2.0 of the

Unit Control Software, the remote start/stop switch is connected to R and W1.

Fig. 11 — Field Control Remote Start/Stop

13