HEAT ANTICIPATOR SETTING — The room thermostat

heat anticipator must be properly adjusted to ensure proper

heating performance. Set the heat anticipator, using an am-

meter between the W and R terminals to determine the

exact required setting.

NOTE: For thermostat selection purposes, use 0.18 amp for

the approximate required setting.

Failure to make a proper heat anticipator adjustment will

result in improper operation, discomfort to the occupants of

the conditioned space, and inefficient energy utilization; how-

ever, the required setting may be changed slightly to provide

a greater degree of comfort for a particular installation.

TRANSFORMER PROTECTION — The unit transformer

protection may be one of 2 types.

The first transformer type may contain an auto. reset over-

current protector for control circuit protection. If this device

trips, it may reset without warning, starting the heating or

cooling section of this product. Use caution when servicing;

if overcurrent protector continues to trip, there is a problem

in the low-voltage electrical circuit, such as an electrical short,

ground, or transformer overload. Disconnect power, correct

the condition, and check for normal unit operation.

The second transformer type is of the energy-limiting type.

It is set to withstand a 30-second overload or shorted

secondary condition.

PRE-START-UP

Failure to observe the following warnings could result

in serious personal injury:

1. Follow recognized safety practices and wear protec-

tive goggles when checking or servicing refrigerant

system.

2. Do not operate compressor or provide any electric

power to unit unless compressor terminal cover is in

place and secured.

3. Do not remove compressor terminal cover until all

electrical sources are disconnected.

4. Relieve and reclaim all refrigerant from system be-

fore touching or disturbing anything inside terminal

box if refrigerant leak is suspected around compres-

sor terminals.

5. Never attempt to repair soldered connection while re-

frigerant system is under pressure.

6. Do not use torch to remove any component. System

contains oil and refrigerant under pressure. To re-

move a component, wear protective goggles and pro-

ceed as follows:

a. Shut off gas supply and then electrical power to

unit.

b. Relieve and reclaim all refrigerant from system

using both high- and low-pressure ports.

c. Cut component connecting tubing with tubing cut-

ter and remove component from unit.

d. Carefully unsweat remaining tubing stubs when

necessary. Oil can ignite when exposed to torch

flame.

Proceed as follows to inspect and prepare the unit for ini-

tial start-up:

1. Remove all access panels.

2. Read and follow instructions on all WARNING, CAU-

TION, and INFORMATION labels attached to, or shipped

with, unit.

3. Make the following inspections:

a. Inspect for shipping and handling damages such as bro-

ken lines, loose parts, disconnected wires, etc.

b. Inspect for oil at all refrigerant tubing connections and

on unit base. Detecting oil generally indicates a re-

frigerant leak. Leak-test all refrigerant tubing connec-

tions using electronic leak detector, halide torch, or

liquid-soap solution. If a refrigerant leak is detected,

see Check for Refrigerant Leaks section on page 23.

c. Inspect all field- and factory-wiring connections. Be

sure that connections are completed and tight.

d. Inspect coil fins. If damaged during shipping and han-

dling, carefully straighten fins with a fin comb.

4. Verify the following conditions:

Do not purge gas supply into the combustion cham-

ber. Do not use a match or other open flame to check

for gas leaks. Failure to follow this warning could

result in an explosion causing personal injury or death.

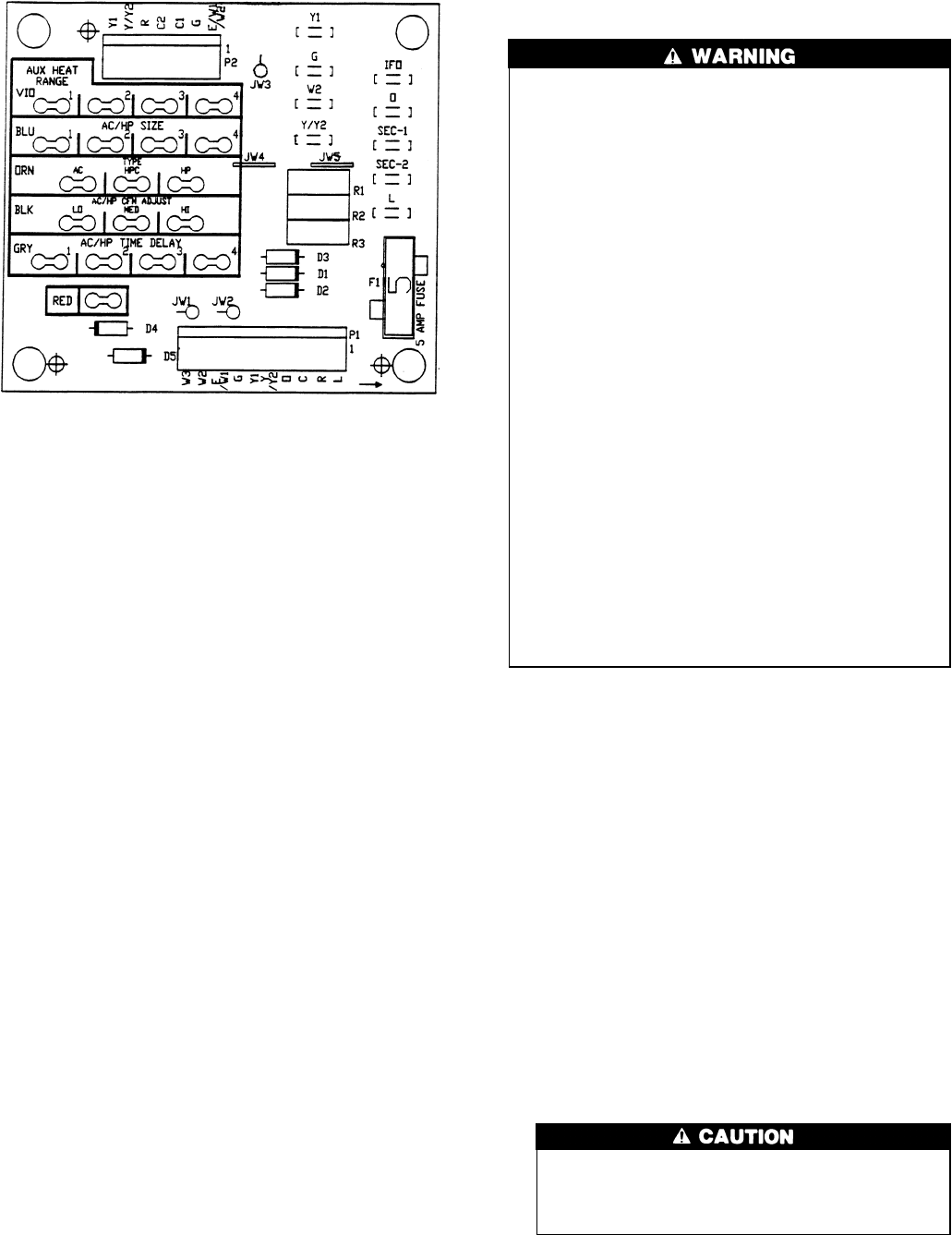

LEGEND

IFO — Indoor (Evaporator) Fan On

JW — Jumper Wire

Fig. 22 — Easy Select Interface Board

22