8

Please Do Not Return This Product To The Store. Contact your local Wayne-Dalton dealer. To find your local Wayne-Dalton dealer, refer to your local

yellow pages business listings or go to the Find a Dealer section online at www.Wayne-Dalton.com

Tools Needed:

1

#1 End and center hinge

2

Hinges

Power Drill

7/16” Socket Driver

NOTE: Refer to the door section identification on page

5 to determine your lock (second), intermediate I

(third), intermediate II (fourth), intermediate III (fifth),

intermediate IV (sixth), intermediate V (seventh) and

top sections. Measure your sections to make sure

they are the correct height as indicated on the chart.

Locate the bottom section, using #1 hinges for the

end stiles and depending on the width of your door,

enough #1 hinge(s) for each of the center stile(s)

location.

NOTE: The #1 hinges serve as end hinges and center

hinges on the bottom section. The #1 hinges also

serve as center hinges at all center hinge locations.

Place the hinges on the section so that the lower (#)

leaf of the hinge is over the pre-punched holes in

the #1 and #4 of the end stiles and the pre-punched

holes of the center stile(s) at the top of the section.

Secure the hinges to the section using (2) 1/4” - 14

x 7/8” self tapping screws for each, then insert the

roller into the appropriate end hinge tube.

Repeat for all other sections using #2 end hinges

second section (lock section), or the #3 end hinges

third section (intermediate section), or the #4 end

hinges fourth section (intermediate section II), or

the #5 end hinges fifth section (intermediate section

III), or the #6 end hinges sixth section (intermediate

section IV), or the #7 seventh section (intermediate

section V) of the door.

NOTE: If you have windload option codes 1124, 1125,

1142, or 1144: Double end hinges and long shaft

roller are required on each end of each section.

IMPORTANT: WHEN PLACING ROLLERS INTO END

HINGES NUMBER 2 AND HIGHER, THE ROLLER GOES

INTO TUBE FURTHEST AWAY FROM SECTION.

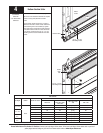

1

Roller

placement

Typical hinge

stamping location

Single end hinge

(2) 1/4”- 14 x 7/8”

Self drilling screws

End hinge

Short shaft

roller

End stile

#1

#4

1

2

3

4

5

6

7

7

6

5

4

3

2

1

END STILE HOLE

PATTERN (LEFT SIDE

IS SHOWN. RIGHT

SIDE IS OPPOSITE.)

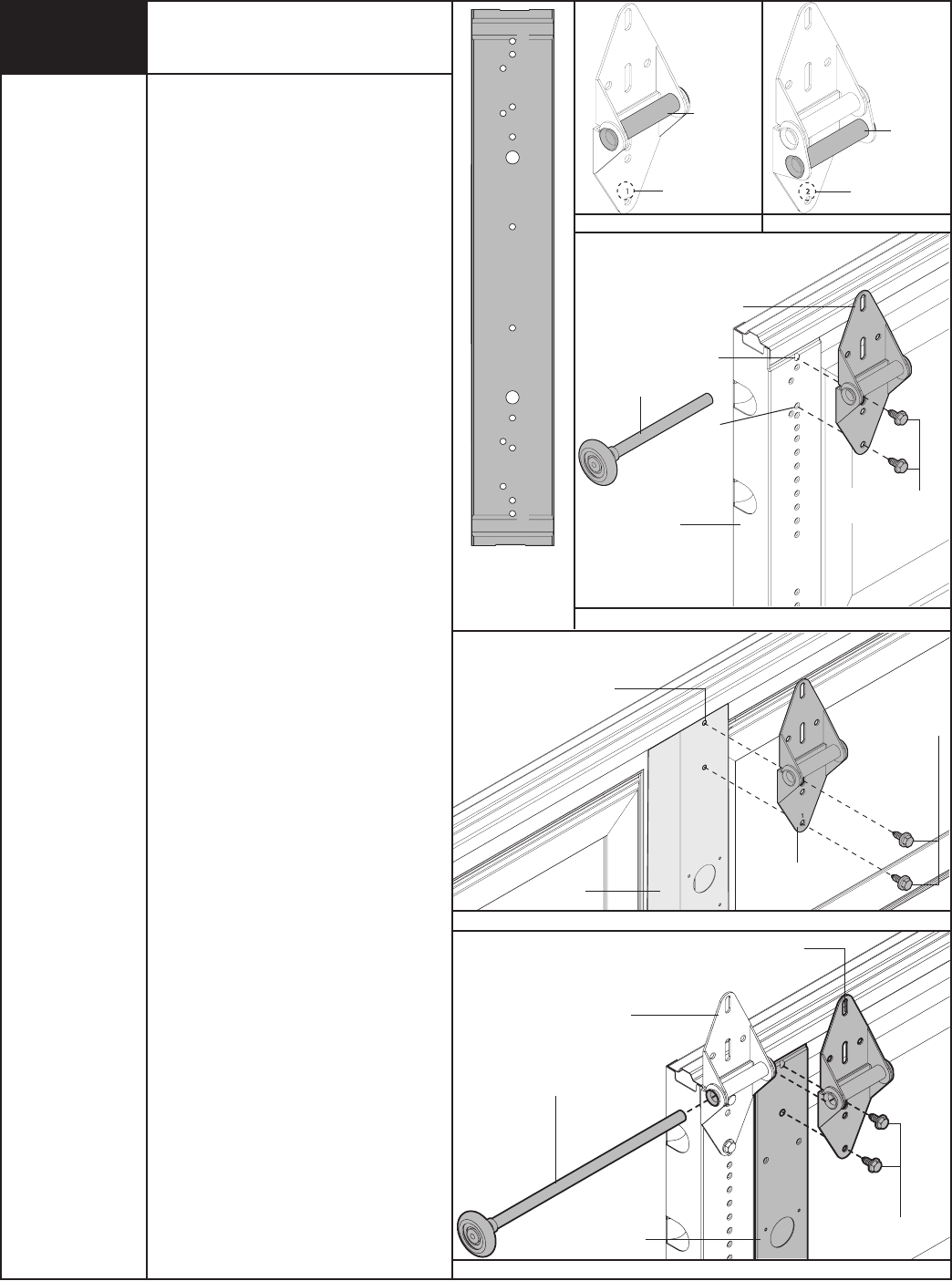

2

#2 Thru #7 End hinges

Roller

placement

Typical hinge

stamping location

Center

hinge

(2) 1/4”- 14 x 7/8”

Self drilling screws

Center

stile

1

1

Previously installed

end hinge

Long shaft roller

End hinge

(2) 1/4”- 14 X 7/8”

Self drilling screws

Stile

Double end hinge

Center hinge

Pre-punched holes

in center stile