6

Please Do Not Return This Product To The Store. Contact your local Wayne-Dalton dealer. To find your local Wayne-Dalton dealer, refer to your local

yellow pages business listings or go to the Find a Dealer section online at www.Wayne-Dalton.com

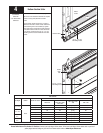

Preparing the Opening

Weather

seal

Headroom

Backroom

Header

Jamb

Jamb

Door

height

Level

header

Plumb

jambs

Header board

2” x 6” lumber

recommended

Suitable mounting surface

2” x 6” lumber minimum

Door width

If you just removed your existing door or you are installing a new door, complete all steps in

PREPARING THE OPENING.

To ensure secure mounting of track brackets, side and center bearing brackets, or steel angles

to new or retro-fit construction, it is recommended to follow the procedures outlined in DASMA

Technical Data Sheets #156, #161 and #164 at www.dasma.com.

The inside perimeter of your garage door opening should be framed with wood jamb and header

material. The jambs and header must be securely fastened to sound framing members. It is

recommended that 2” x 6” lumber be used. The jambs must be plumb and the header level.

The jambs should extend a minimum of 14” (356 mm) above the top of the opening for Torsion

spring applications. For low headroom applications, the jambs should extend to the ceiling height.

Minimum side clearance required, from the opening to the wall, is 3-1/2” (89 mm).

IMPORTANT: CLOSELY INSPECT EXISTING JAMBS, HEADER AND MOUNTING SURFACE. ANY WOOD

FOUND NOT TO BE SOUND, MUST BE REPLACED.

For Torsion spring applications, a suitable mounting surface must be firmly attached to the wall,

above the header at the center of the opening. The mounting surface must be 2” x 6” lumber

minimum (Select southern yellow pine lumber. Do not use lumber marked as spruce-pine-fur or

SPF). The mounting surface must be securely attached to the wall with four (4) 3/8” anchors for

masonry constructions or four (4) 5/16” x 4” lag screws for wood construction.

NOTE: Drill a 3/16” pilot hole in the mounting surface to avoid splitting the lumber. Do not attach

the mounting surface with nails.

FAILURE TO SECURELY ATTACH A SUITABLE MOUNTING PAD TO STRUCTURALLY SOUND FRAMING

MEMBER COULD CAUSE SPRINGS TO VIOLENTLY PULL MOUNTING PAD FROM WALL, RESULTING IN

SEVERE OR FATAL INJURY.

Weather Seal (May Not Be Included):

Cut the weather seal if necessary to fit the header and jambs.

Align the header seal with the inside edge of the header and temporarily secure it to the header

with equally spaced nails. Next, fit the jamb seals up tight against the header seal and flush with

the inside edge of the jamb. Temporarily secure the jamb seals with equally space nails. This will

keep the bottom section from falling out of the opening during installation. Equally space nails

approximately 12” to 18” apart.

NOTE: Do not permanently attach weather seal to the jamb at this time.

HEADROOM REQUIREMENT: Headroom is defined as the space needed above the top of the door

for tracks, springs, etc. to allow the door to open properly. If the door is to be motor operated,

2-1/2” (64 mm) of additional headroom is required.

BACKROOM REQUIREMENT: Backroom is defined as the distance needed from the opening back

into the garage to allow the door to open fully.

NOTE: For door heights from 10’1” to 14’0”, refer to your operator manufacture installation

instructions for appropriate depth into room.

WARNING

HEADROOM REQUIREMENT

TRACK TYPE Torsion

12” 12 1/2”

15” 14 1/2”

BACKROOM REQUIREMENT

WEATHER SEAL

DOOR HEIGHT TRACK

MANUAL

LIFT

MOTOR

OPERATED

8’3” - 9’0” 12”, 15” Radius 126” 168”

9’3” - 10’0” 12”, 15” Radius 138” 168”

10’1” - 12’0” 12”, 15” Radius 162” -

12’1” - 14’0” 12”, 15” Radius 186” -

Jamb

Weather

seal