FIN-PRC004-EN60

Mechanical

Specifications

Recommended Schedule and Installation

Procedure

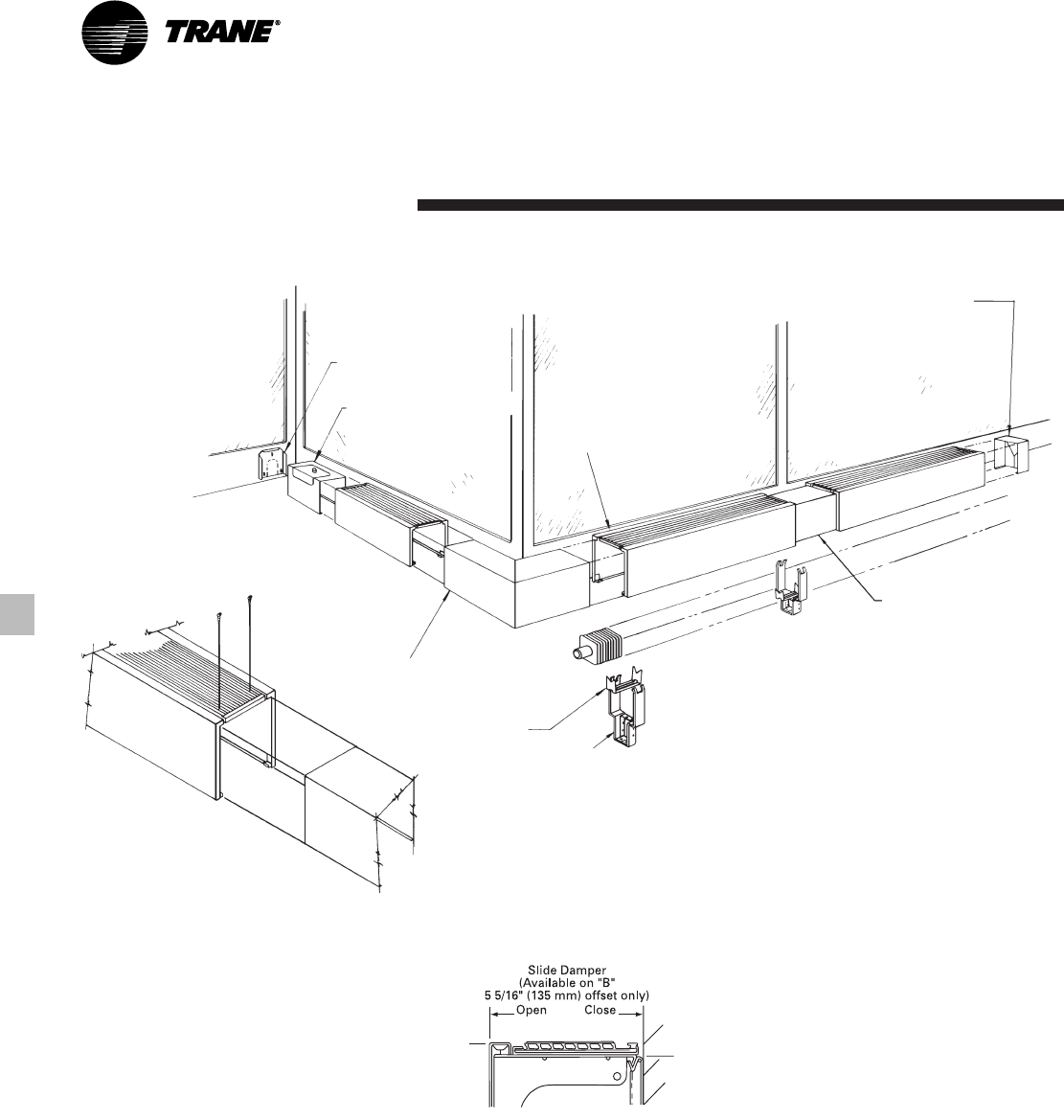

1.Layout job selecting enclosure lengths

with appropriate wall sleeve at each joint.

Space enclosures to suit. At end of run

use wall sleeve or 3” (76 mm) end to suit

job.

2.Layout pedestal bracket assembly so the

center-line is 7

1

/2” (191 mm) from each

end of enclosure to avoid interference

with enclosure gussets. Locate 1 pedestal

bracket assembly at center of enclosures

longer than 4 ft. (1.22 m).

NOTE: Schedule enclosures to overlap

accessories 1”-3” (25-76 mm) except ends

1”-2” (25-51 mm) with access door overlap

max. 1” (25 mm).

Slide Damper (SD) — Optional

The slide damper assembly consisting of two

integrated extruded aluminum clear anodized

grille plates provide air discharge control by

front to back positioning which requires no

mechanical actuating parts.

Note: Fasten accessory with 6 S.M. Screw

through solid part of grille. Drill 37 (104)

holes into accessory when in position.

One wide enclosure shown.

Installation Layout for Pedestal Mount E3A-1W One Wide Enclosure

Wall Sleeve Support

(Slotted For Piping

Where Specified)

Wall Sleeve 4” (102 mm)

or 8

3

/8” (213 mm)

(Access Door Optional

8

3

/8” (213 mm) Only)

Corner — Inside and/or

Outside Short Leg

Dimension 8

3

/8” (213 mm)

Cradle

Pedestal Bracket Assembly

Enclosure Assembly — Typical

3” (76 mm) End Assembly

Wall Sleeve in Run

At Each Joint