Routine Maintenance

50 CAH-SVX01A-EN

See “

ƽ

WARNING Hazardous

Voltage with Capacitors!” on

page 49 regarding

disconnection of power.

Drain Pans

The condensate drain pan and drain

line must be checked to assure the

condensate drains as designed. This

inspection should occur a minimum

of every six months or more often as

dictated by operating experience.

If evidence of standing water or

condensate overflow exists, identify

and remedy the cause immediately.

Refer to the “Troubleshooting”

section on page 56 for possible

causes and solutions.

To clean drain pans:

1 Disconnect all electrical power to

the unit.

2 Wearing the appropriate

personal protective equipment,

remove any standing water.

3 Scrape solid matter off of the

drain pan.

4 Vacuum the drain pan with a

vacuum device that uses high-

efficiency particulate arrestance

(HEPA) filters with a minimum

efficiency of 99.97 percent at

0.3 micron particle size.

5 Thoroughly clean all areas with a

mild bleach and water solution or

an EPA-approved sanitizer

specifically designed for HVAC

use.

6 Immediately rinse the affected

surfaces thoroughly with fresh

water and a fresh sponge to

prevent potential corrosion of

metal surfaces.

7 Allow the unit to dry completely

before putting it back into

service.

8 Be careful that any contaminated

material does not contact other

areas of the unit or building.

Properly dispose of all

contaminated materials and

cleaning solution.

Fans

Inspecting and Cleaning

Fans

Fan sections of air handlers should

be inspected every six months at a

minimum or more frequently if

operating experience dictates. If

evidence of microbial growth (mold)

is found, identify and remedy the

cause immediately. Refer to the

“Troubleshooting” section on

page 56 for possible causes and

solutions. To clean the fan section:

1 Disconnect all electrical power to

the unit.

2 Wearing the appropriate

personal protective equipment,

remove any contamination.

3 Vacuum the section with a

vacuum device that uses high-

efficiency particulate arrestance

(HEPA) filters with a minimum

efficiency of 99.97 percent at

0.3 micron particle size.

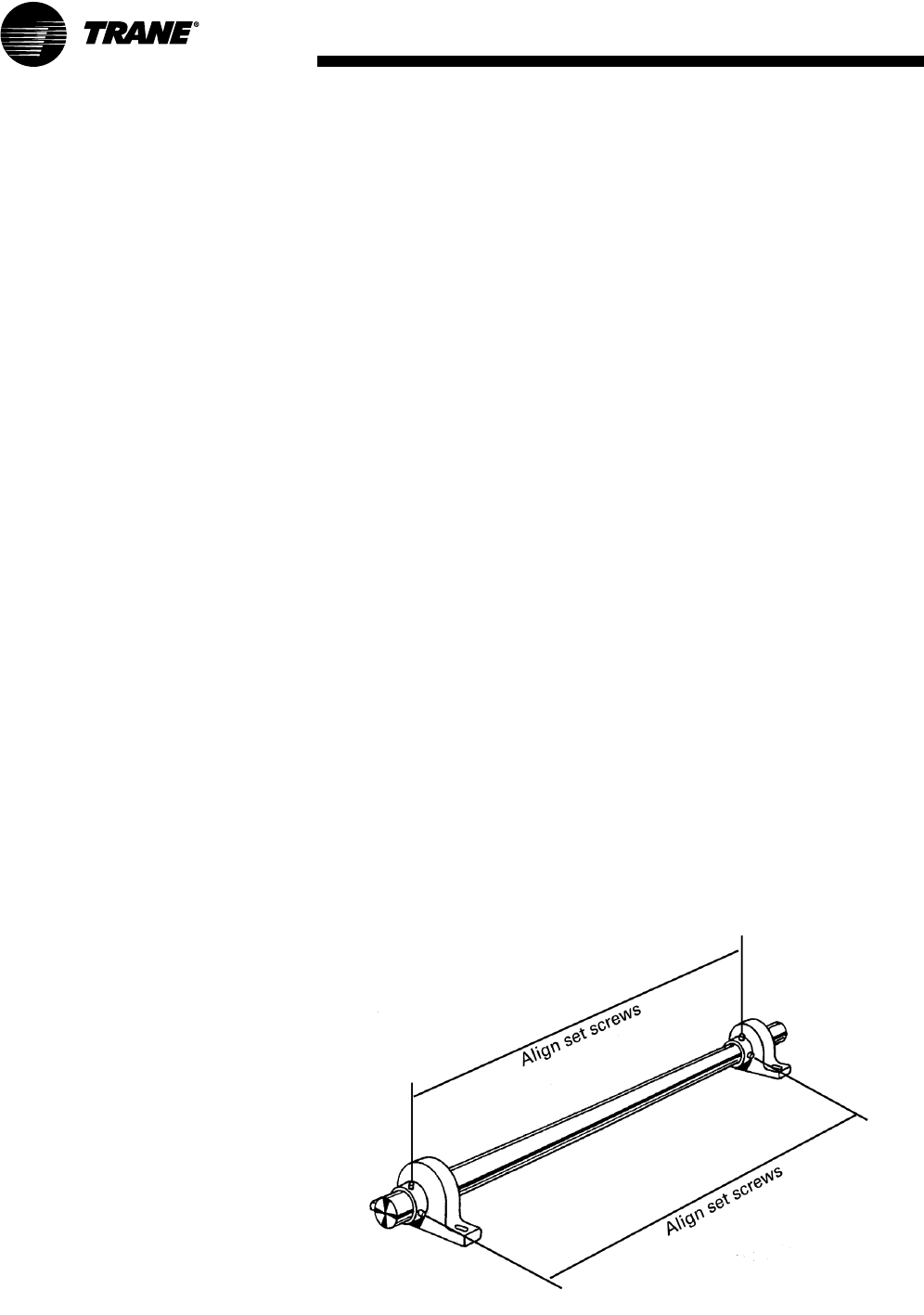

Figure 49. Bearing set screw alignment

4 Thoroughly clean all areas with a

mild bleach and water solution or

an EPA-approved sanitizer

specifically designed for HVAC

use.

5 Immediately rinse the affected

surfaces thoroughly with fresh

water and a fresh sponge to

prevent potential corrosion of

metal surfaces.

6 Allow the unit to dry completely

before putting it back into

service.

7 Be careful that any contaminated

material does not contact other

areas of the unit or building.

Properly dispose of all

contaminated materials and

cleaning solution.

Bearing Set Screw

Alignment

Align bearing set screws as

illustrated in Figure 49. Table 4 on

page 47 provides bearing set screw

torque measurements.