Startup

CAH-SVX01A-EN 45

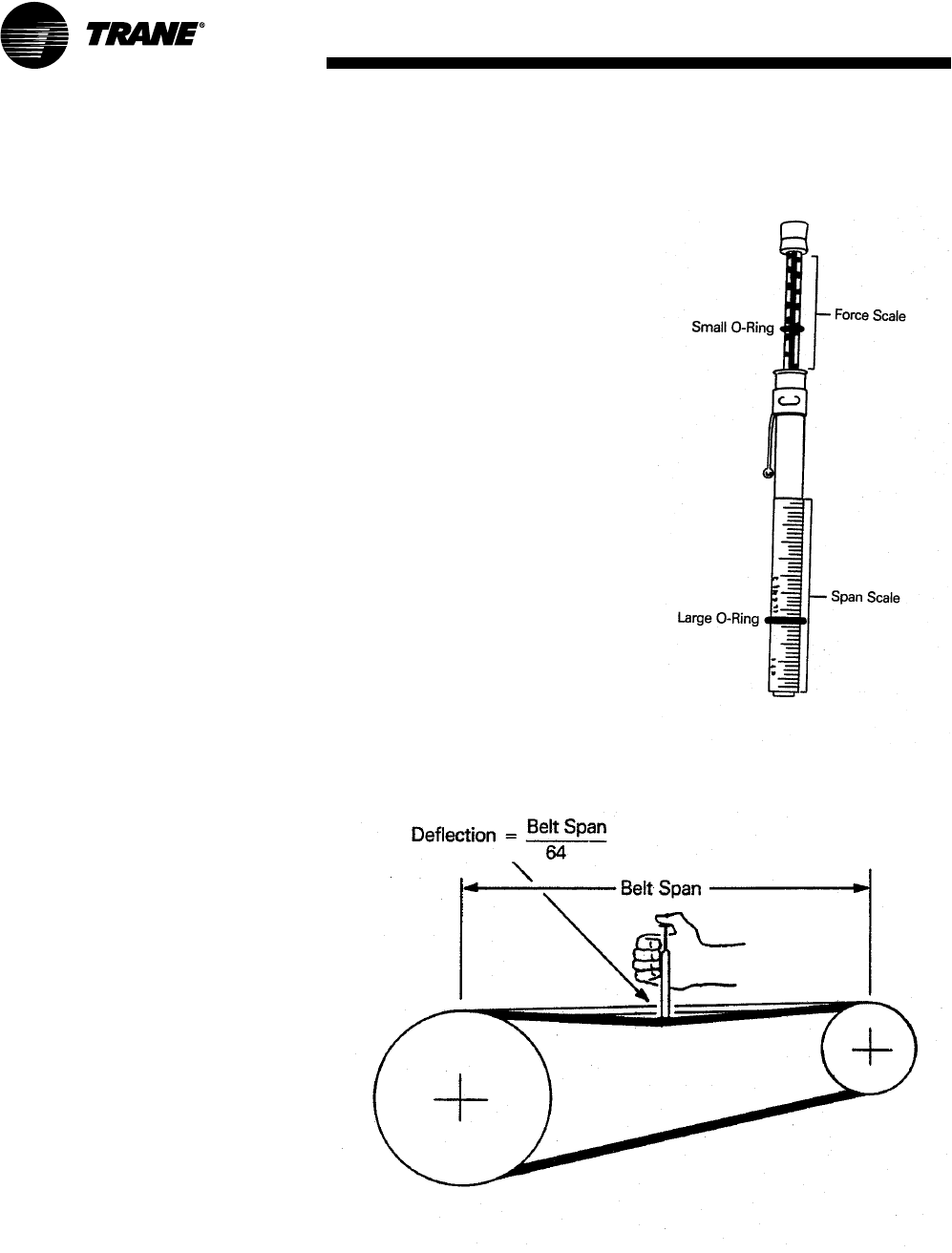

Tension the Fan Belt

Check the fan belt tension at least

three times during the first days of

operation because there is a rapid

decrease in tension until the belt

settles in (see Figure 46 and

Figure 47).

ƽ WARNING

Hazardous Voltage with

Capacitors!

Disconnect all electric power,

including remote disconnects and

discharge all motor start/run

capacitors before servicing. Follow

proper lockout/tagout procedures to

ensure the power cannot be

inadvertently energized. For variable

frequency drives or other energy

storing components provided by

Trane or others, refer to the

appropriate manufacturer’s

literature for allowable waiting

periods for discharge of capacitors.

Verify with an appropriate voltmeter

that all capacitors have discharged.

Failure to disconnect power and

discharge capacitors before

servicing could result in death or

serious injury.

CAUTION

Tension Belts Correctly!

Over-tensioning belts can cause

damage to bearings, shafts, and

drive components. Under tensioning

belts is the primary cause of

premature belt failure. Belts should

not squeal at startup. Recheck belt

tension after 8 hours, 24 hours, and

100 hours of operation and monthly

thereafter.

Proper belt tension is required to

ensure maximum bearing and drive

component life and is based on

motor horsepower requirement. A

label located on the bearing support

on the drive side of the unit lists all

drive parts, the proper belt tension,

and deflection for that tension for

the specific drive.

If the drive is changed from the

original, proper belt tension can be

estimated using Table 3.

The correct operation tension for a

V-belt drive is the lowest tension at

which the belts will not slip under

the peak load conditions. It may be

necessary, however, to increase the

tension of some drives to reduce

excessive belt flopping or to reduce

excessive startup squealing.

Figure 46. Belt tension measurement

Figure 47. Belt tensioner