Installation

34 CAH-SVX01A-EN

• Thermal expansion valve. The

expansion valve is the throttling

device that meters the

refrigerant into the evaporator

coil. Metering too much

refrigerant floods the

compressor; metering too little

elevates the compressor

temperature. Choosing the

correct size and type of

expansion valve is critical to

assure it will correctly meter

refrigerant into the evaporator

coil throughout the entire

operating envelope of the

system. Correct refrigerant

distribution into the coil requires

an expansion valve for each

distributor.

The thermal expansion valve must

be selected for proper size and

capacity. The size of the expansion

valve should cover the full range of

loadings. Check that the valve will

successfully operate at the lightest

load condition. For improved

modulation, choose expansion

valves with balanced port

construction and external

equalization.

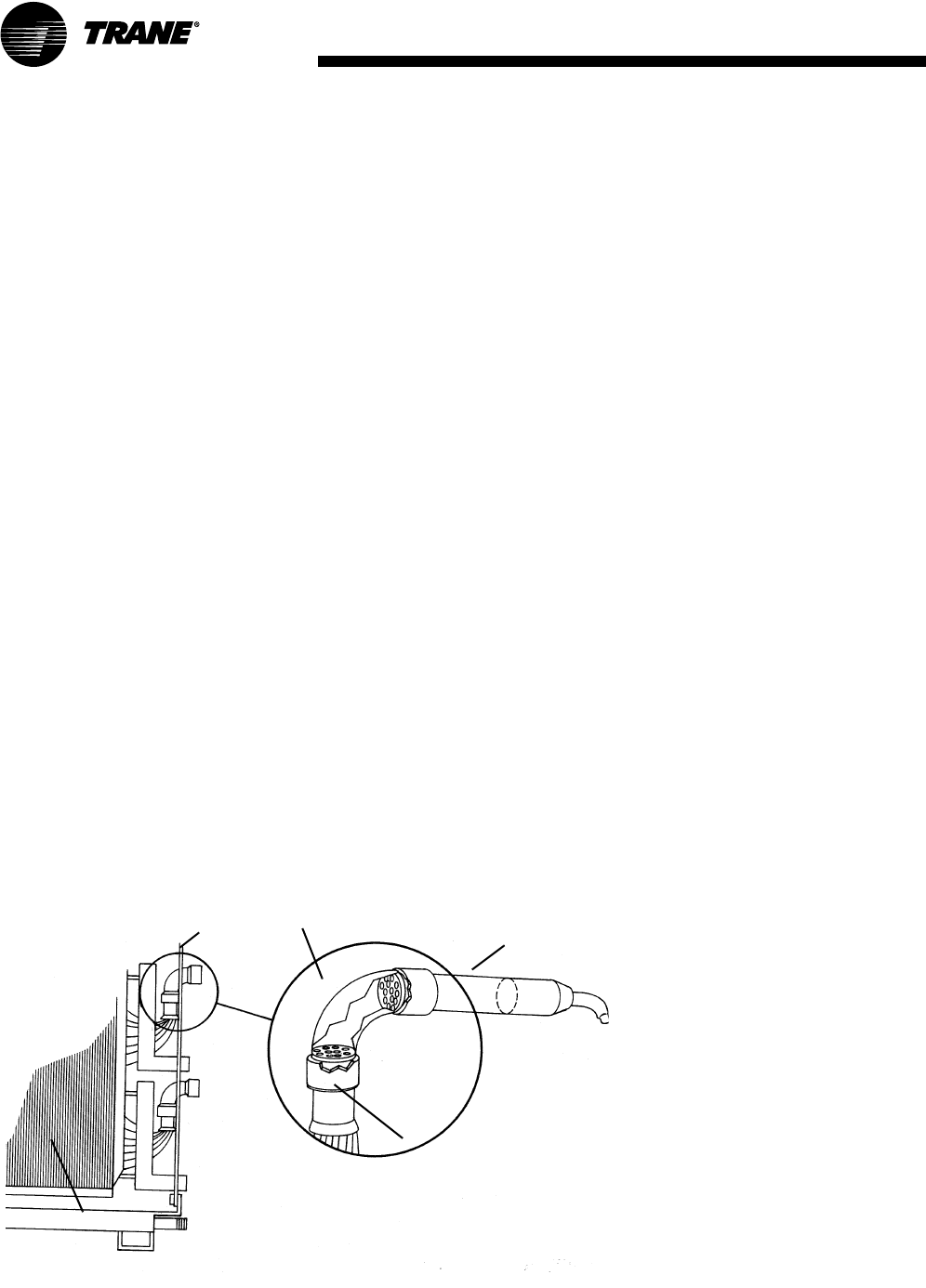

Figure 34. Type F refrigerant coil with packed elbow

Panel

Perforated plate

(packed elbow)

Cut here for

piping

Venturi type

distributor

Coil

Cut the process tube and cap

assembly from the liquid connection

as shown in Figure 34 and install the

expansion valve directly to the liquid

connections.

CAUTION

Valve Damage!

Disassemble the thermal expansion

valve before completing the brazing

connections. If necessary, wrap the

valve in a cool, wet cloth while

brazing. Failure to protect the valve

from high temperatures may result

in damage to internal components.

Suction Lines

Line sizing. Proper suction-line

sizing is required to guarantee the

oil returns to the compressor

throughout the system’s operating

envelope. At the same time, the line

must be sized so that the pressure

drop does not excessively affect

capacity or efficiency. To accomplish

both objectives, it may be necessary

to use two different line diameters:

one for the horizontal run and for

vertical drops, and another for the

vertical lifts.

Routing. To prevent residual or

condensed refrigerant from “free-

flowing” toward the compressor,

install the suction line so it slopes

slightly—that is, by 1/4-inch to 1-inch

per 10 feet of run [1 cm per 3 m]—

toward the evaporator. When the

application includes a suction riser,

oil must be forced to travel the

height of the riser. Riser traps and

double risers are unnecessary in the

suction line when the refrigerant coil

is used with Trane condensing units.

Avoid putting refrigerant lines

underground. Refrigerant

condensation or installation debris

inside the line, service access, and

abrasion/corrosion can quickly

impair reliability.

Insulation. Any heat that transfers

from the surrounding air to the

cooler suction lines increases the

load on the condenser (reducing the

system’s air-conditioning capacity)

and promotes condensate formation

(adversely affecting indoor air

quality). After operating the system

and testing all fittings and joints to

verify the system is leak-free,

insulate the suction lines all the way

to inner side panel to prevent heat

gain and unwanted condensation.

Components. Installing the suction

line requires field installation of

these components: a filter, access

port, and a Frostat™ control when

the refrigerant coil is used with

Trane condensing units. Position

them as close to the compressor as

possible.

Note: Placement of the Frostat

control is illustrated in Figure 33.

• Filter. The suction filter prevents

contaminants, introduced during

installation, from entering the

compressor. For this reason, the

suction filter should be the

replaceable-core type, and a

clean core should be installed

after the system is cleaned up.

• Access port. The access port is

used to determine suction

pressure. This port is usually a

Schraeder valve with a core.