Startup

CAH-SVX01A-EN 47

Determine Fan

Speed

ƽ WARNING

Rotating Components!

During installation, testing,

servicing and troubleshooting of

this product it may be necessary to

measure the speed of rotating

components. Have a qualified or

licensed service individual who has

been properly trained in handling

exposed rotating components,

perform these tasks. Failure to

follow all safety precautions when

exposed to rotating components

could result in death or serious

injury.

Fan speed can be determined using

a strobe-type tachometer, or

revolution counter.

Check unit vibration if the fan speed

is changed more than 5 percent from

the original designed speed, or if

parts such as shafts, fan wheels,

bearings, or other drive components

are replaced. Do not exceed the

maximum fan speed.

Pay particular attention to any

vibration, noise, or overheating of

the motor and fan bearings;

however, note that bearings may run

warm during break in.

Sheave Alignment

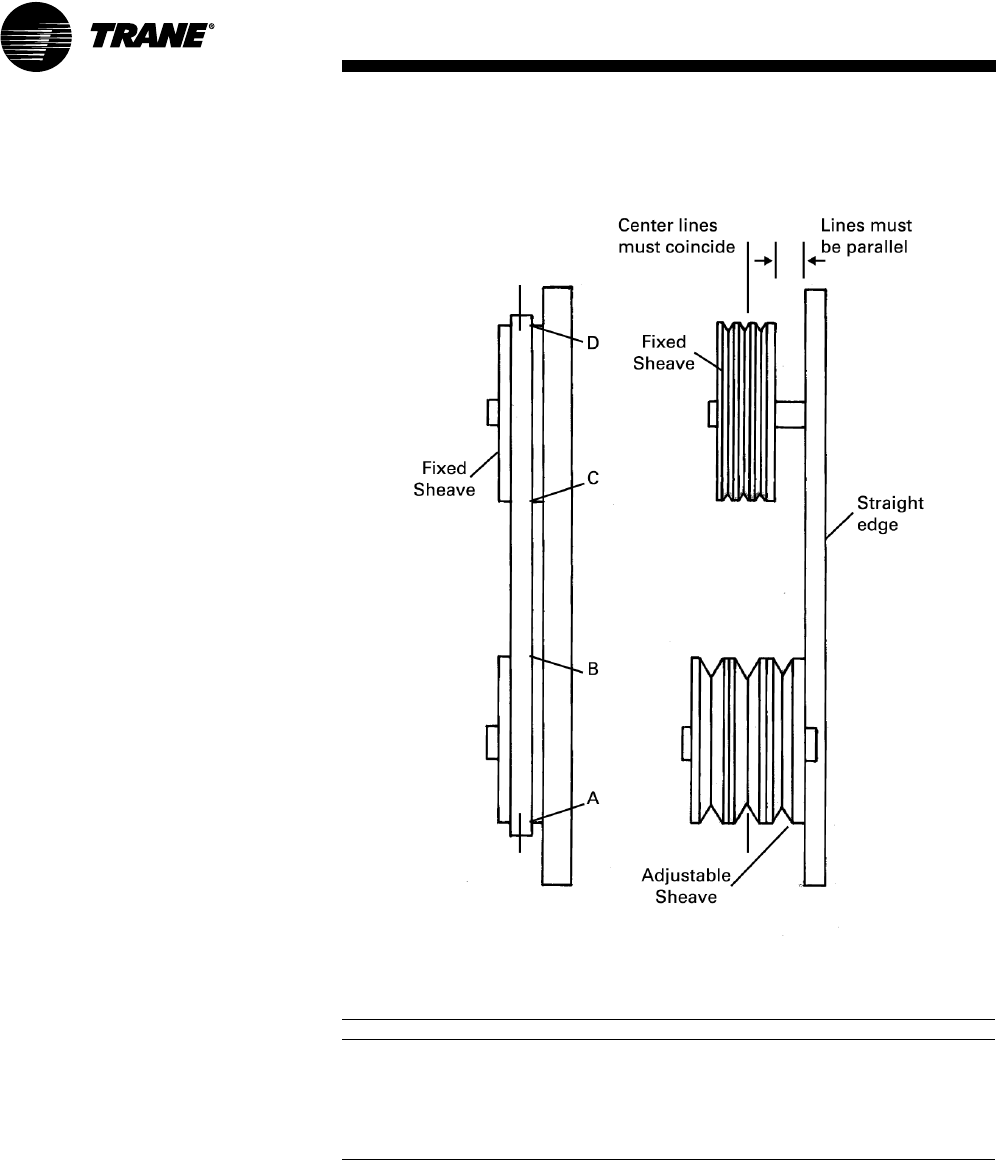

Align the fan and motor sheaves

using a straightedge. The

straightedge must be long enough

to span the distance between the

outside edges of the sheaves. When

the sheaves are aligned, the

straightedge will touch both sheaves

at points A through D (see

Figure 48) to confirm the shaft is

parallel. For uneven width sheaves,

place a string in the center groove of

both sheaves and pull tight. Adjust

the sheaves and tighten the sheave

set screws to the proper torque

given in Table 4.

Multibelt Check

Tighten the belts slightly and rotate

the drive several times.

On multiple belt drives, ensure the

force of deflection is approximately

the same on each belt by pushing

each belt in an equal distance at a

point halfway from each sheave (see

Figure 48). If this force is not the

Figure 48. Proper drive alignment

Table 4. Fan and drive compound torque settings (inches)

Screw Size Hex Key Square Head Hex Head Torque (in.-lb.) Torque (ft.-lb.)

1/4 1/8 3/8 7/16 66-90 5.5-7.5

5/16 5/32 1/2 1/2 126-164 10.5-13.7

3/8 3/16 9/16 9/16 228-300 19.0-25.0

7/15 7/32 5/8 5/8 348-450 29.0-37.5

1/2 1/4 3/4 3/4 504-650 42.0-54.2

5/8 5/16 15/16 15/16 1290-1390 107.0-116.0

same for each belt, the motor and

fan shaft are not parallel. Realign as

required. After realignment, tighten

the belts again to the standard belt

tensioning specifications. If the force

is still not the same for all belts, the

belts or sheaves are worn and must

be replaced.