Installation

32 CAH-SVX01A-EN

unless the condensate is drained by

gravity into a receiver, vented to

atmosphere, and returned to the

condensate pump.

6 Pitch all supply and return steam

piping down 1 inch for every

10 feet in the direction of the

steam or condensate flow.

Note: Do not drain the steam mains

or take-offs through the coils. Drain

the mains ahead of the coils through

a steam trap to the return line.

7 Ensure overhead returns have

1 psig of pressure at the steam

trap discharge for every 2 feet of

elevation for continuous

condensate removal.

Water Coil Piping

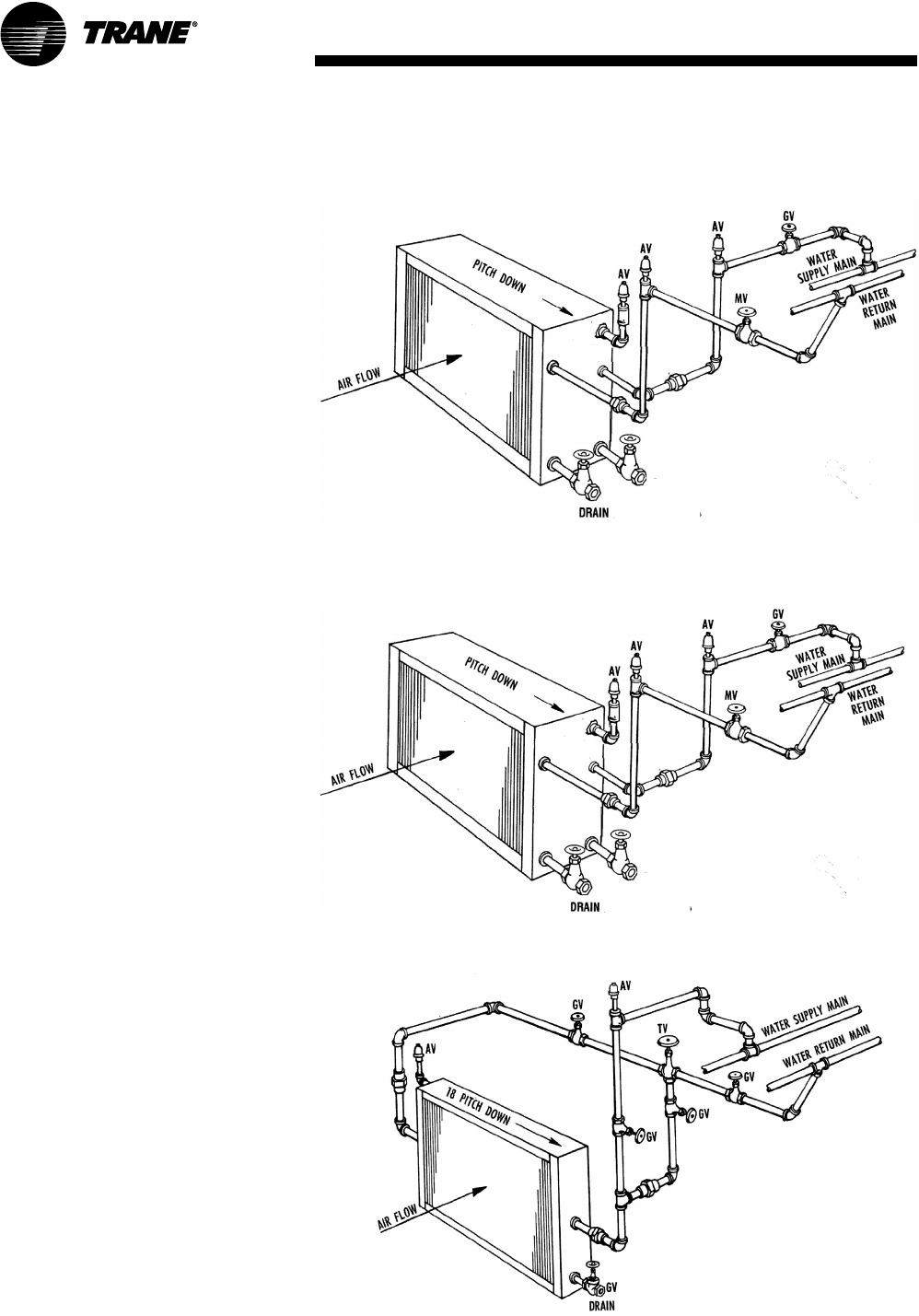

Figure 30 through Figure 32

illustrate typical water coil piping

configurations.

Type WA, 5A, 5W, D, K, W, UW, TT,

P,2, P4, and P8 water coils are self-

venting only if the water velocity

exceeds 1.5 feet per second (fps) in

the coil tubes. Type UU, WD, and 5D

water coils are self-venting only if

the water velocity exceeds 2.5 fps in

the coil tubes. See the unit

submittals for coil water velocity. If

the water velocity is below these

minimums, vent the coil by one of

the following methods:

• Install an air vent in the top pipe

plug tapping of the return

header.

• When the return line rises above

the top of the coil, vent from the

top of the return header

horizontally to the return piping.

Note: T, ST, and TT coils are

designed with larger than normal

end tube sheet holes to allow for

maximum expansion. Air leakage

around tubes should be expected

and handled by capping over coil

ends or by sealing around tubes

with a pliable sealant such as

silicone.

Figure 30. Typical piping for type 5W one-row water coil

Figure 31. Typical piping for type 5A, 5W two-row, K, W 3- to 12-row, WD, D, and

DD water coils

Figure 32. Typical piping for type W or WA 1-row water coil