Installation

24 CAH-SVX01A-EN

Duct Connections

All duct connections to the units

should be installed in accordance

with the standards of the National

Fire Protection Association (NFPA)

for selecting and installing of air

conditioning and ventilating

systems other than residence type

(NFPA 90A), and residence type

warm air heating and air

conditioning systems (NFPA 90B).

To ensure the highest fan efficiency,

duct turns and transitions must be

made carefully, minimizing air

friction losses and turbulence.

Proper duct work installation by such

organizations as SMACNA (Sheet

Metal and Air Conditioning

Contractors National Association,

Inc.) should be adhered to.

Component

Installation

Requirements

Each component in the Custom air

handler may have installation

requirements that could affect the

unit’s performance.

Note: For components included in

the unit but not included in this

manual, reference the component

manufacturers specific Installation,

Maintenance, and Operation

manual. Copies of these manuals

are either included in the package

with this unit IOM or are attached to

the components mounted in the

unit.

Fans

The fan and motor assembly are

internally isolated. The fan and

motor bases are bolted to a

minimum of four spring isolators.

The isolators are secured to the fan

section support base. Shipping tie-

down blocks are bolted to the

isolators between the fan base and

the isolator support frame.

To activate the isolation, remove the

shipping tie-down blocks. Retain

these blocks for use in adjusting

isolators if necessary.

Isolator Adjustment

Note: Isolators are pre-adjusted and

set at the factory. Follow this

procedure only if necessary and as it

applies to the isolators used in this

unit. This procedure, for isolators

can, and should be, performed by

one person to ensure that the proper

sequence is followed.

Isolators are selected for distribution

of equipment weight, but may not all

compress the same. This procedure

assumes the base surface is level.

Isolators are not intended to be

leveling devices.

1 Verify that the shipping bolts that

hold the fan base in a fixed

position have been removed.

2 Remove the jam nut on top of the

isolator adjusting stud at the first

isolator to be adjusted. Check

that the shipping block is in

place.

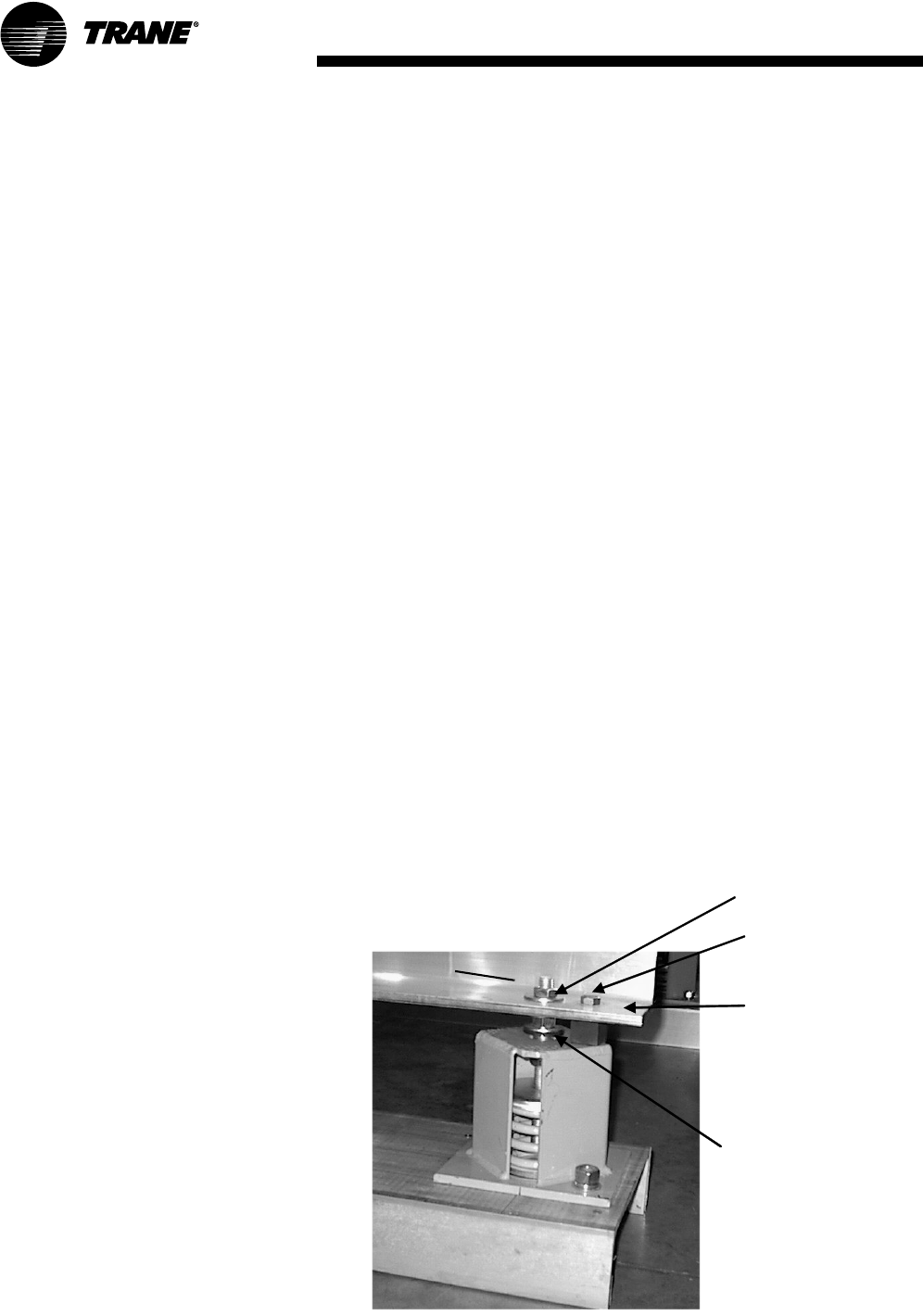

Figure 19. Isolator

SHIPPING TIE-

DOWN BLOCK

(SHIM)

ADJUSTING

NUT

JAM NUT

SHIPPING

BOLT

FAN BASE

ƽ WARNING

Hazardous Voltage with

Capacitors!

Disconnect all electric power,

including remote disconnects and

discharge all motor start/run

capacitors before servicing. Follow

proper lockout/tagout procedures to

ensure the power cannot be

inadvertently energized. For variable

frequency drives or other energy

storing components provided by

Trane or others, refer to the

appropriate manufacturer’s

literature for allowable waiting

periods for discharge of capacitors.

Verify with an appropriate voltmeter

that all capacitors have discharged.

Failure to disconnect power and

discharge capacitors before

servicing could result in death or

serious injury.

Note: For additional information

regarding the safe discharge of

capacitors, see PROD-SVB06A-EN.

Turn the adjusting nut 2 or 3 turns

only, counterclockwise on each

isolator in a sequenced manner. The

equipment weight will compress the

spring inside the housing

approximately 1/4 inch.