– 12 –

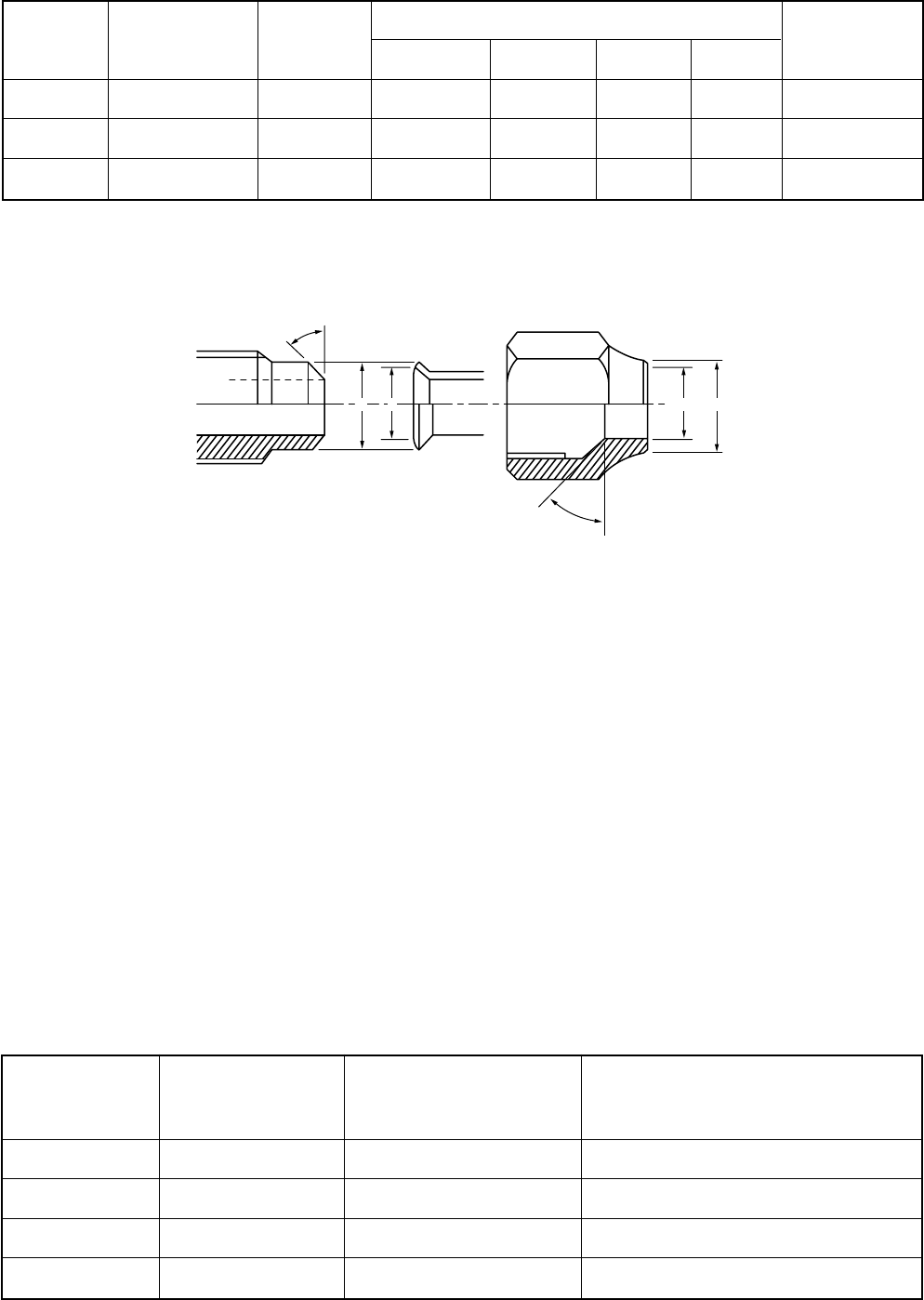

43˚ to 45˚

45˚ to 46˚

B A

C

D

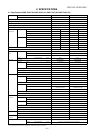

Table 3-2-6 Flare and flare nut dimensions for R22

Fig. 3-2-2 Relations between flare nut and flare seal surface

2. Flare Connecting Procedures and Precautions

a) Make sure that the flare and union portions do not have any scar or dust, etc.

b) Correctly align the processed flare surface with the union axis.

c) Tighten the flare with designated torque by means of a torque wrench. The tightening torque for R410A is

the same as that for conventional R22. Incidentally, when the torque is weak, the gas leakage may occur.

When it is strong, the flare nut may crack and may be made non-removable. When choosing the tighten-

ing torque, comply with values designated by manufacturers. Table 3-2-7 shows reference values.

NOTE :

When applying oil to the flare surface, be sure to use oil designated by the manufacturer.

If any other oil is used, the lubricating oils may deteriorate and cause the compressor to burn out.

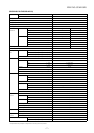

Table 3-2-7 Tightening torque of flare for R410A [Reference values]

Nominal

diameter

1/4

3/8

1/2

Outer diameter

(mm)

6.35

9.52

12.70

Tightening torque

lbf.ft (N•m)

10 to 13 (14 to 18)

24 to 31 (33 to 42)

37 to 46 (50 to 62)

Tightening torque of torque

wrenches available on the market

lbf.ft (N•m)

12 (16), 13 (18)

31 (42)

41 (55)

Nominal

diameter

1/4

3/8

1/2

Outer diameter

(mm)

6.35

9.52

12.70

Thickness

in. (mm)

0.0315 (0.8)

Dimension in. (mm)

A B C D

0.354 (9.0)

0.362 (9.2) 0.256 (6.5)

0.512 (13)

0.512 (13.0) 0.531 (13.5) 0.382 (9.7) 0.787 (20)

0.630 (16.0) 0.508 (12.9)

Flare nut width

in. (mm)

0.669 (17)

0.866 (22)

0.945 (24)

0.0315 (0.8)

0.0315 (0.8)

0.638 (16.2)

0.787 (20)

FILE NO. SVM-10020

in.

in.