5.0 Site Requirements

18

© Baxi Heating UK Ltd 2009

5.9 Condensate Drain - General

Failure to install the condensate discharge pipework

correctly will affect the reliable operation of the boiler.

1. Ensure the discharge of condensate complies with any

national or local regulations in force.

BS 6798 & Part H1 of the Building Regulations give further

guidance.

2. If any further drain pipe is required (additional to that supplied

with the boiler), it should be run in a proprietary material

e.g. PVC, PVC-U, ABS, PVC-C or PP. John Guest ‘Speedfit’

components are recommended.

3. Metal pipework is NOT suitable for use in condensate

discharge systems.

4. Any pipe fitted externally must be kept as short as possible to

minimise the potential of freezing and must be insulated using

waterproof material.

5. When discharging condensate into a soil stack or waste pipe

the effects of existing plumbing must be considered.

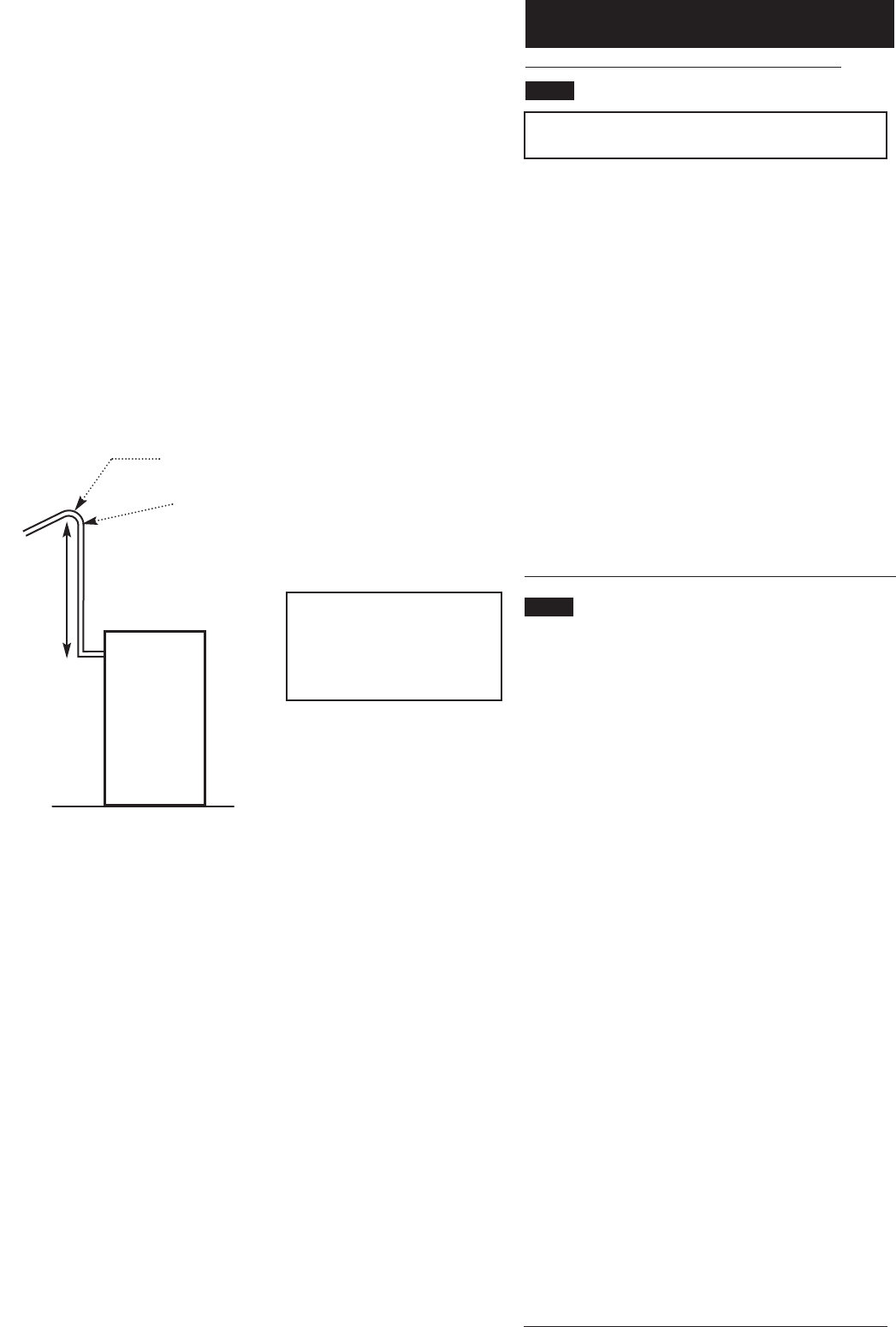

5.10 Condensate Disposal (Fig. 12)

1. This boiler incorporates an automatic pumped condensate

system. The pump is submerged in a sump assembly and is

activated by the discharge float switch. A second (safety) float

switch is fitted.

2. The pump has an effective head of 3.5 metres. The

condensate outlet is positioned at the top right front of the

boiler. It is 10mm diameter plastic.

3. 3.5 metres of flexible 10mm condensate discharge pipe and a

10mm push fit elbow are supplied with the boiler.

4. The 10mm pipe can be routed to a maximum of 3.5 metres

vertically and then discharge via gravity or be routed

horizontally. A combination of vertical and horizontal runs is

permissible.

5. The pipe must be adequately supported, either using suitably

spaced clips or run within larger diameter pipe. When using clips

take care not to deform the pipe.

6. When routing the pipe through a wall it must be suitably

sleeved. Also the pipe must not be exposed to sources of heat,

and should be protected in locations where it may be damaged.

7. The pipe should be routed so that any sharp bends, dips and

loops are avoided. A minimum radius of 100mm is

recommended for any bends. No slope is necessary and air

breaks are not required on the pumped part of the condensate

run.

8. Any part of the condensate drain system that is outside the

dwelling, or in an unheated part of it must be at least 21.5mm

diameter.

Boiler

Max. Head

3.5 metres

Gravity Drain

min. fall 3°

Min. radius 100mm

Note: The point of discharge from the

pumped length of condensate pipe

(point ‘A’) must be 150mm above the

base level of the boiler, whether

discharging direct into a drain or into

an additional gravity drain.

Point ‘A’

Fig. 12