4.0 System Details

14

© Baxi Heating UK Ltd 2009

4.7 Sealed Systems (cont)

4. Expansion Vessel. A diaphragm type expansion vessel to

BS 4814:1 shall be fitted close to the inlet side of the pump.

The connecting pipework should not be less than 15mm.

Pipework connecting the expansion vessel should not

incorporate valves of any sort.

Methods of supporting the vessel are supplied by the vessel

manufacturer.

The nitrogen or air charge pressure of the expansion vessel

shall not be less than the hydrostatic head, (height of the

top point of the system above the expansion vessel). To

size the expansion vessel it is first necessary to calculate the

volume of water in the system in litres. The following

volumes may be used as a conservative guide to calculating

the system volume.

Boiler Heat Exchanger: 1.55 litres

Small Bore Pipework: 1 litre per kW of system output

Micro Bore Pipework: 7 litre

Steel Panel Radiators: 8 litre per kW of system output

Low Water Capacity Radiators: 1 litre per kW of system output

Hot Water Cylinder: 1 litre per kW of system output

If the system is extended, the expansion vessel volume may

have to be increased unless provision has been made for

extension. Where a vessel of the calculated size is not

available, the next available larger size should be used.

The boiler flow temperature is controlled at approx. 75°C.

The vessel size can now be determined from the

information in table 1 where V = System volume in litres.

5. Cylinder. The hot water cylinder must be an indirect

coiler type.

6. Method of Make Up. Provision shall be made for

replacing water loss from the system either:-

a) From a make up vessel or tank mounted in a position

higher than the top point of the system and connected

through a non-return valve to the system on the return side

of the hot water cylinder or the return side of all heat

emitters.

or

b) Where access to a make up vessel would be difficult by

using the mains top up method or a remote automatic

pressurisation and make up unit.

7. Mains Connection. There shall be no connection to the

mains water supply or to the water storage tank which

supplies domestic hot water even through a non-return

valve, without the approval of the Local Water Authority.

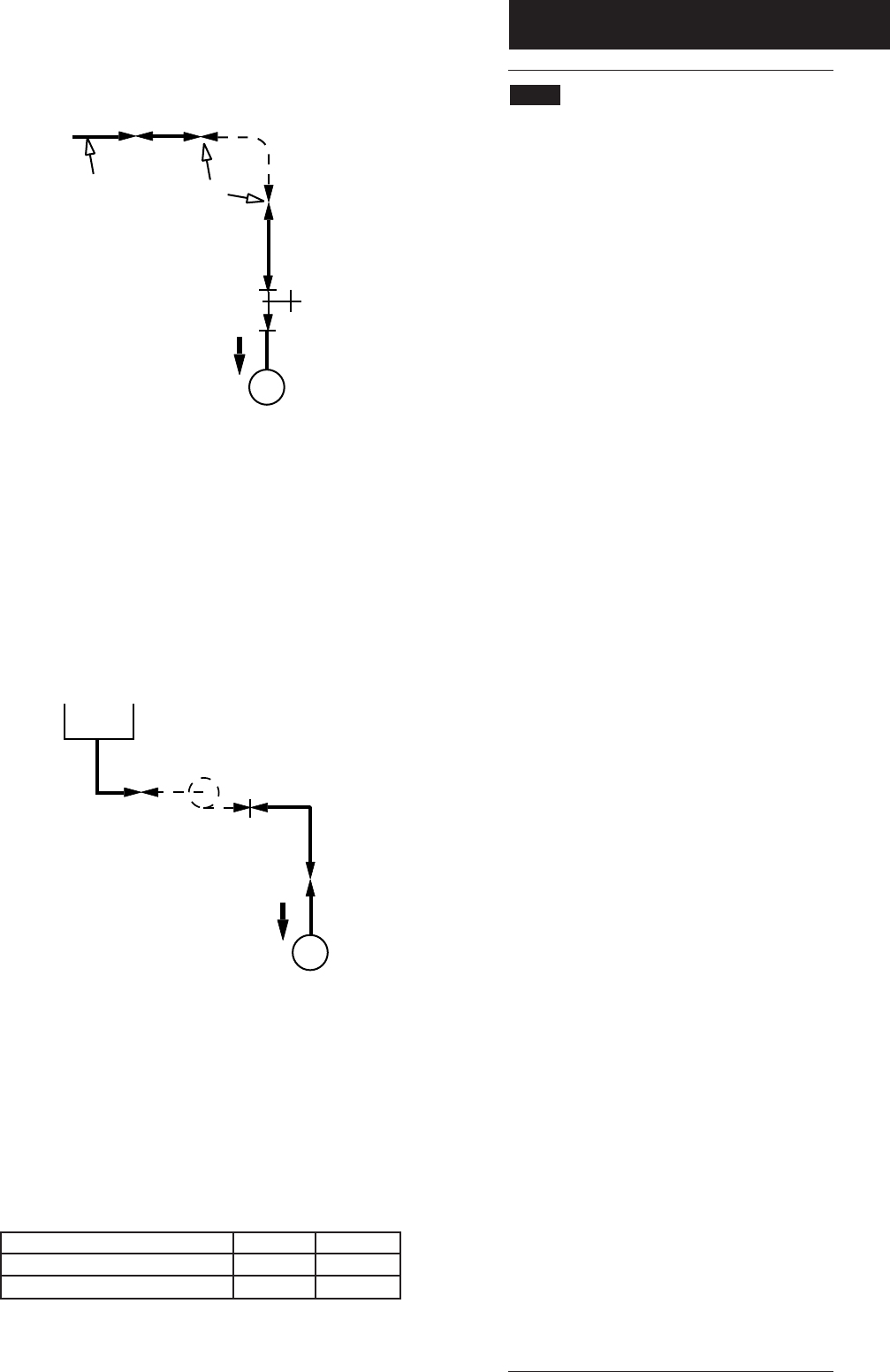

8. Filling Point. A filling point connection on the central

heating return pipework must be provided to facilitate initial

filling and pressurising and also any subsequent water loss

replacement/refilling.

The sealed primary circuits may be filled or replenished by

means of a temporary connection between the circuit and a

supply pipe, provided a ‘Listed’ double check valve or some

other no less effective backflow prevention device is

permanently connected at the inlet to the circuit and the

temporary connection is removed after use.

The filling method adopted must be in accordance with all

relevant water supply regulations and use approved

equipment.

Your attention is drawn to: for GB: Guidance G24.2 and

recommendation R24.2 of the Water Regulations Guide. for

IE: the current edition of IS 813 “Domestic Gas

Installations”.

Double

Check

Valve

Heating

System

Temporary

Hose

Hose

Union

Stop

Valve

Mains Water

Supply

(Service Pipe)

Heating

System

Pressure Pump

Reducing Valve

(if required)

Cistern

Stop

Valve

Mains Water

Supply

Filling a Sealed Water System (Method 1)

Mains Topping Up Method

NOTE: This method of filling a sealed system

may only be used if acceptable to Local Water

Undertaking

Filling a Sealed Water System (Method 2)

Cistern Filling Method

NOTE: Cistern to be supplied through a

temporary connection from a service pipe or

cold water distributing pipe

Vessel Charge Pressure (bar)

Initial System Pressure (bar)

Expansion Vessel Volume (litres)

0.5

1.0

V x 0.11

1.5

1.0

V x 0.087

Table 1

Fig. 7

Fig. 8