4.3 Pipework

1. The sizes of the flow and return pipes from the

boiler should be determined by normal methods

according to the requirements of the system.

2. It is recommended that the system is designed for a

drop in temperature across the system of between

11& 20°C.

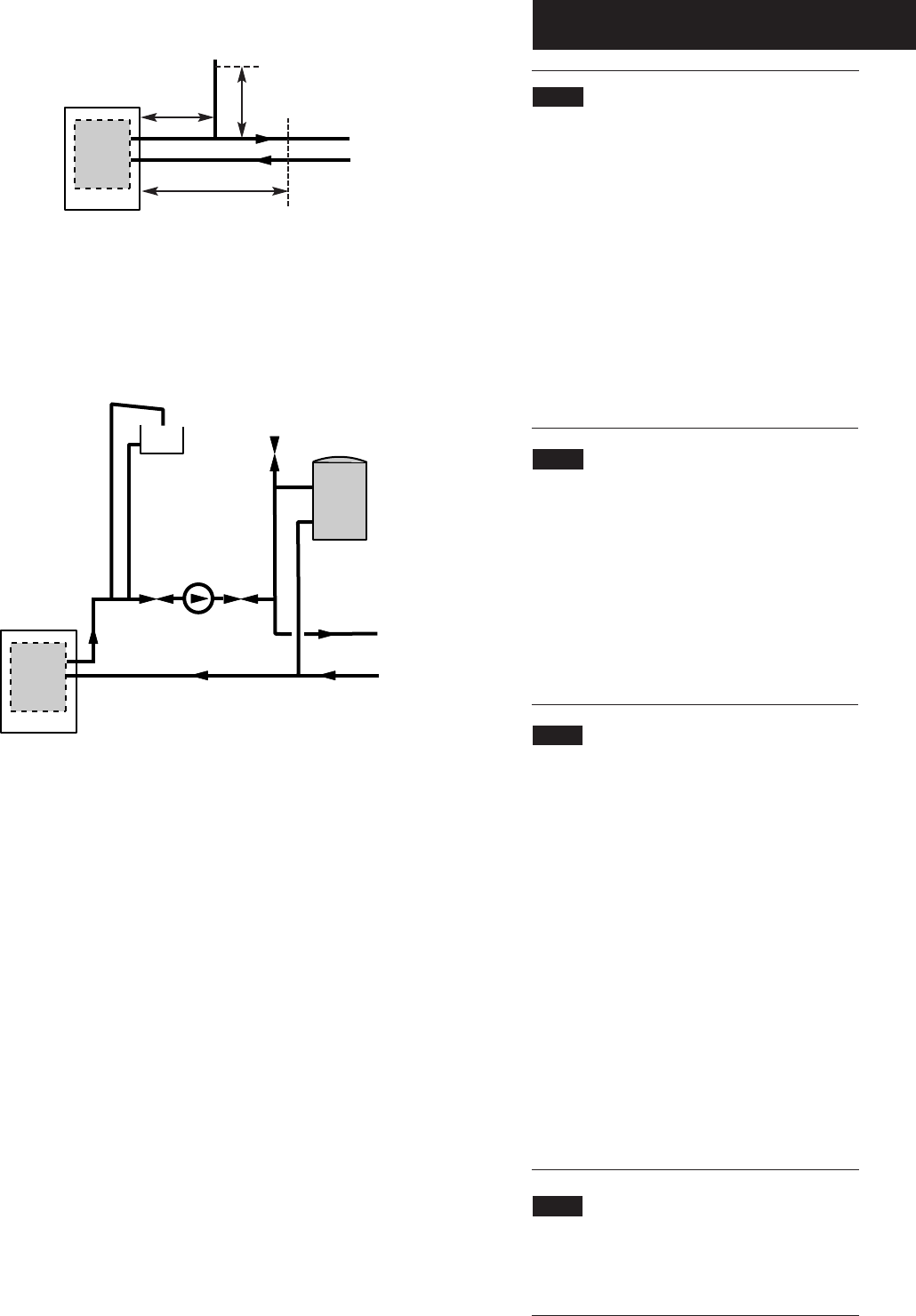

3. In systems using non-metallic pipework it is

necessary to use copper pipe for the boiler Flow and

Return. The copper must extend at least 1 metre from

the boiler and include any branches. The copper pipe

must not be insulated (Fig. 4).

4.4 System Controls

1. The system in which the appliance is installed should

include a control system.

2. Such a system would comprise a timer control and a

separate room and/or cylinder thermostat as

appropriate.

3. The boiler should be controlled so that it operates

on demand only.

4.5 Fully Pumped Open Vent System (Fig. 5)

1. The sizes of the system pipes should be determined

by normal methods.

2. The open vent pipe should be a minimum of 22mm

and must rise continuously to a point above the feed

and expansion tank.

3. The flow pipe from the boiler form part of the vent

pipe. No part of the open vent may contain a valve.

4. Inverted pipe runs must be avoided.

5. On low capacity systems with a maximum available

flow rate of less than 8.3l/min (temperature differential

›25°C) an external bypass must be fitted .

6. The bypass must be of the automatic pressure

operated type.

4.6 Storage Systems

1. For information regarding the use of a Bermuda

BBU 15 HE boiler with a storage system, contact the

appropriate storage system manufacturer.

4.0 System Details

12

© Baxi Heating UK Ltd 2009

Air Vent

Boiler

Pump

Radiator

Circuit

Fully Pumped System

22mm

Open Vent

15mm

Cold

Feed

Indirect

Cylinder

Return

Flow

Fig. 5

Boiler

Flow

Return

Copper

0.5m

Copper

1m

Copper

0.5m

Fig. 4