Usewiringwithatemperaturelimitation of 75 =C mini-

mum. Run the 208 or 230 volt, 60 hertz electric power

supply through a fused disconnect switch to the control

box of the unitand connect as shown in the wiring dia-

gram located on the inside of the control access panel.

The unit must be electrically grounded in accordance with

local codes or, in the absence of local codes, with the

National Electrical Code ANSI/NFPA No. 70 (latest edition)

or CSA C22.2 Part 1 (latest edition).

Power supply to the unit must be NEC Class 1 and must

comply with all applicable codes. A fused disconnect

switch should be field provided for the unit. The switch

must be separate from all other circuits. If any of the wire

supplied with the unit must be replaced, replacement wire

must be of the type shown on the wiring diagram.

Electrical wiring must be sized to minimum circuit

ampacity marked on the unit. Use copper conductors

only. Each unit must be wired with a separate branch

circuit and be properly fused.

OPERATION

Sequence of Operation

Cooling

When the thermostat is in the cooling mode, the O circuit

is powered which energizes the reversing valve. Upon

cooling demand, the thermostat closes circuit R toY and

G. Closing R to Y closes the unit contactor, starting the

compressor and outdoor fan. The thermostat automati-

cally closes R to G circuit which also brings on the indoor

blower at the same time. Upon satisfying cooling demand,

the thermostat will open the above circuits and open the

main contactor, stopping the compressor and outdoor fan.

If the unit is equipped with a time delay, the blower will

continue to operate for 90 seconds which improves

system efficiency.

Heating

Upon heating demand, the thermostat closes circuit R to

Y, which closes the unit contactor, starting the compressor

and outdoor fan. The reversing valve is not energized in

the heating mode. -The thermostat again automatically

brings on the indoor fan at the same time. The second

stage of the thermostat closes circuit R to W, which closes

the unit sequencers, bringing the auxiliary electric heat on.

Upon satisfying heating demand, the thermostat opens

the above circuits and stops unit operation.

Defrost Cycle

Ifthe outdoor ambient conditions are such that frost forms

on the outdoor coil, the defrost control monitors the need

for and initiates and terminates defrost cycles as neces-

sary to maintain system performance. The defrost control

is time/temperature initiated and temperature terminated

with a maximum defrost time (time-out) of 10 minutes.

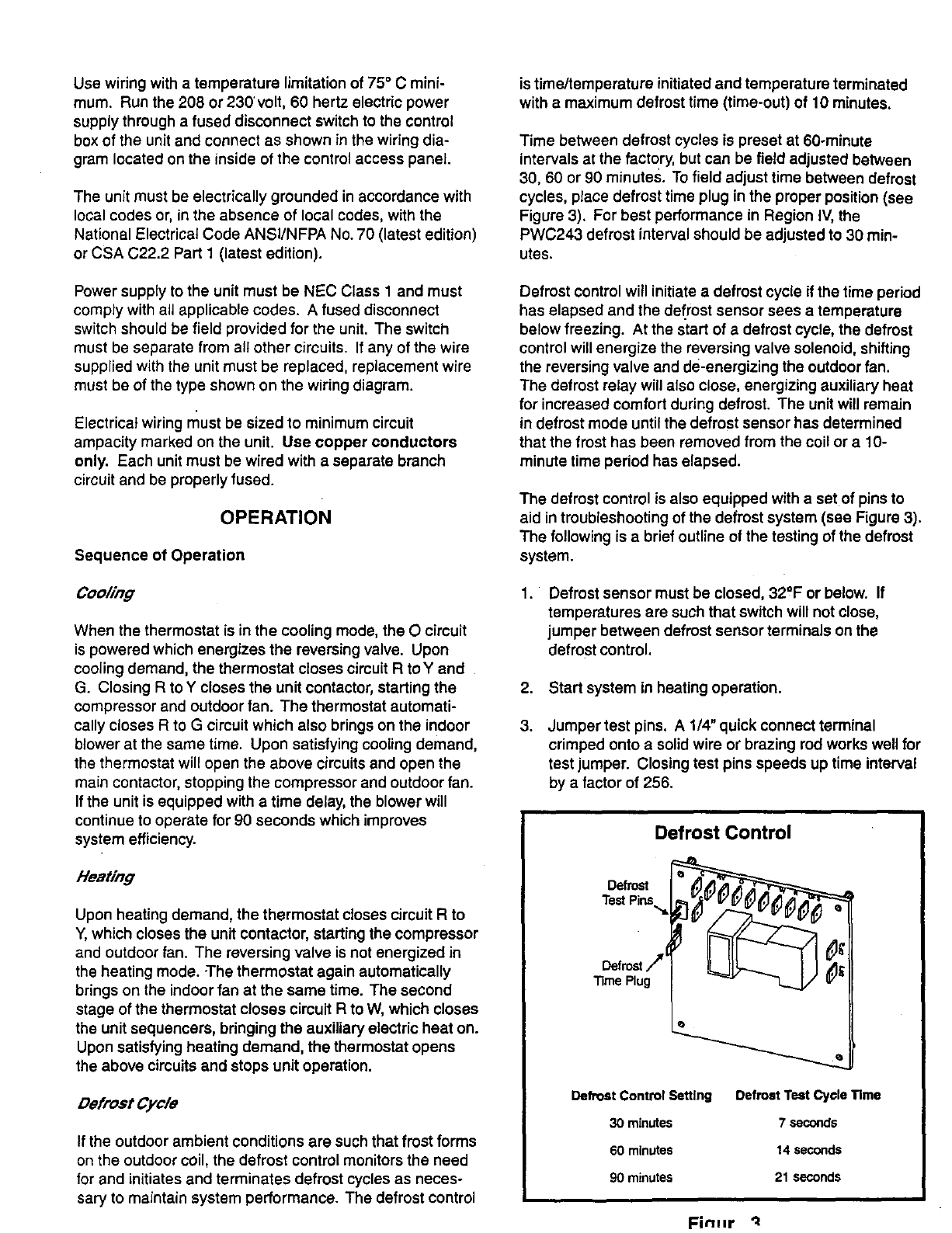

Time between defrost cycles is preset at 60ominute

intervals at the factory, but can be field adjusted between

30, 60 or 90 minutes. To field adjust time between defrost

cycles, place defrost time plug in the proper position (see

Figure 3). For best performance in Region IV, the

PWC243 defrost interval should be adjusted to 30 min-

utes.

Defrost control will initiate a defrost cycle ifthe time period

has elapsed and the defrost sensor sees a temperature

below freezing. At the start of a defrost cycle, the defrost

control will energize the reversing valve solenoid, shifting

the reversing valve and de-energizing the outdoor fan.

The defrost relay will also close, energizing auxiliary heat

for increased comfort during defrost. The unit will remain

in defrost mode until the defrost sensor has determined

that the frost has been removed from the coil or a 10-

minute time period has elapsed.

The defrost control is also equipped with a setof pins to

aid in troubleshooting of the defrost system (see Figure 3).

The following is a brief outline of the testing of the defrost

system.

. Defrost sensor must be closed, 32°F or below. If

temperatures are such that switch will not close,

jumper between defrost sensor terminals on the

defrost control,

2. Start system in heating operation.

.

Jumper test pins, A 1/4" quick connect terminal

crimped onto a solid wire or brazing rod works well for

test jumper. Closing test pins speeds up time interval

by a factor of 256.

Defrost

TestPins.,,,=i

Defro=/

TimePlug

Defrost Control

Defrost Control Setting Defrost Test Cycle Time

30 minutes 7 seconds

60 minutes 14 seconds

90 minutes 21 seconds

FinHr