If the unit is installed in a residential garage, it must be

located or protected to avoid physical damage by vehicles.

The unit must be installed so that no electrical compo-

nents are exposed to water.

I

[A CAUT,ON]

This unit must be installed level to allow for

proper drainage of the chassis base pan and

unit drain pan.

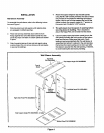

Installing With a Wall Sleeve

[ _, CAUTION l

The sleeve is not intended as the sole support

for the unit. An additional support must be

provided near the return opening on the unit

for adequate support. The use of vibration

isolation material between the unit and the

support is recommended.

Refer to the installation instructions packed with the wall

sleeve and Figure 1 for guidance in assembly and mount-

ing using a wall sleeve.

Make sure the gaskets attached to the sleeve are not

damaged.

Seal the space between the wall sleeve and-the building

opening with non-hardening caulking compound. The seal

must be weathertight to prevent entrance of moisture and

water into the building.

Assure that the unit is completely seated against the

gaskets on the wall sleeve.

Installing Without a Wall Sleeve

Refer to the following directions and Figure I for guidance

in installing the unit without a wall sleeve:

.

Measure the size of the unit and provide an opening in

an outside wall that will accept the unit. Local ordi-

nances may require a steel lintel to support the wall

above the opening. The opening must be square in all

4 corners.

,

Position the unit so that the grilles on the outside face

of the unit are flush or extend beyond the face of the

exterior wall, but not recessed more than 2" from the

face of the building. Provide a support under the

unit, inside the building. Make sure that the inside

support does not block the return air. The unit should

be installed level

.

Seal the space between the unit and building opening

using a non-hardening caulking compound. The seal

mustbe weathertight to prevent entrance of moisture

and water into the building. Make sure the drain holes

in the base are not plugged with caulking,

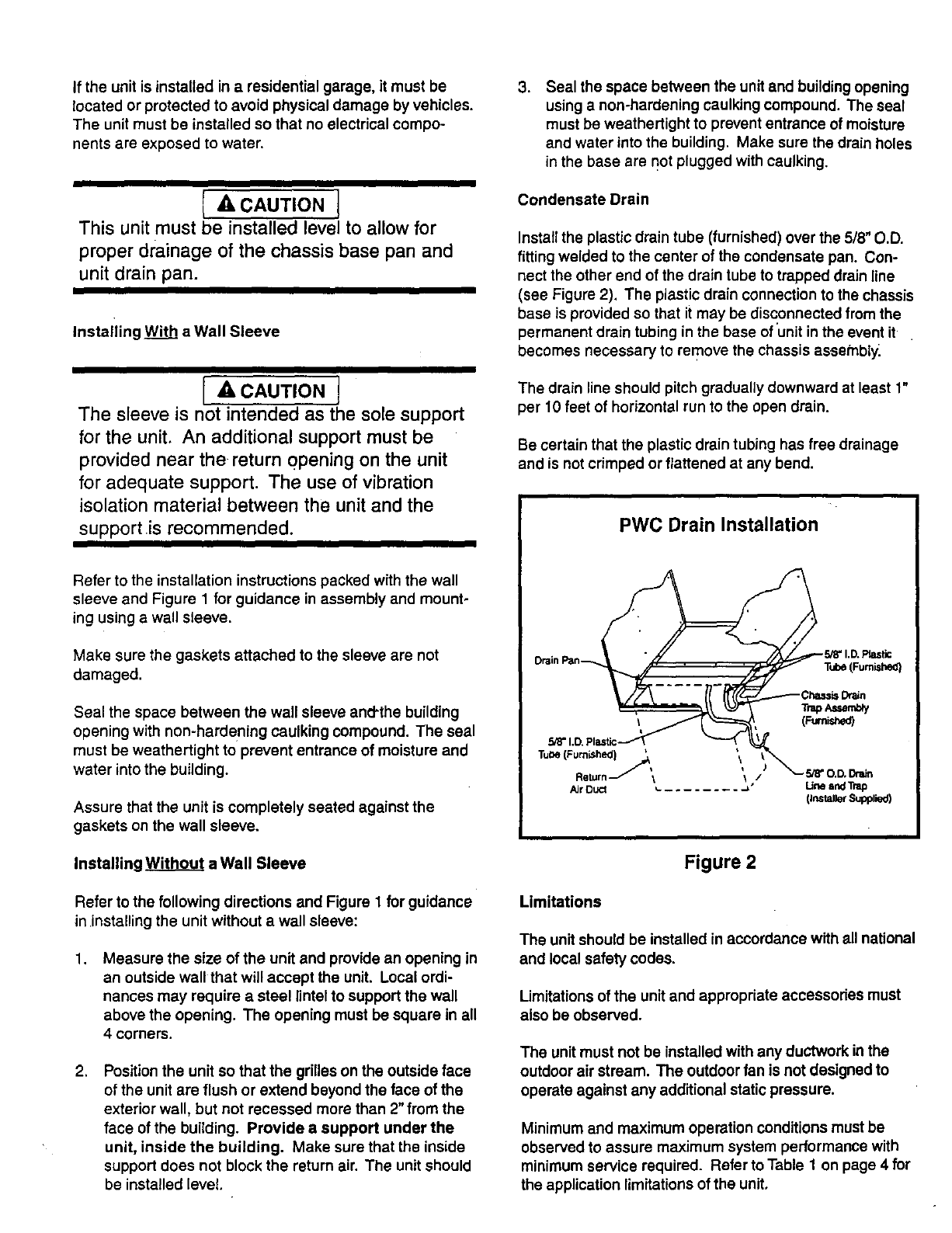

Condensate Drain

Install the plastic drain tube (furnished) over the 5/8" O.D.

fitting welded to the center ofthe condensate pan. Con-

nect the other end of the drain tube to trapped drain line

(see Figure 2). The plastic drain connection to the chassis

base is provided so that it may be disconnected from the

permanent drain tubing in the base of unitin the event it

becomes necessary to remove the chassis assetnbly.

The drain line should pitch gradually downward at least 1"

per 10 feet of horizontal run to the open drain.

Be certain that the plastic drain tubing has free drainage

and is not crimped or flattened at any bend.

PWC Drain Installation

Drain Pan_

Figure 2

Limitations

The unitshould be installed in accordance with all national

and local safety codes.

Limitations of the unit and appropriate accessories must

also be observed.

The unitmust not be installed with any ductwork in the

outdoor air stream. The outdoor fan is not designed to

operate against any additional static pressure.

Minimum and maximum operation conditions must be

observed to assure maximum system performance with

minimum service required. Refer to Table 1 on page 4 for

the application limitations of the unit.