PARTNO. I 41194BOg6I DATE I 2-1-96 I SUPERSEDESI 411940094 I PAGE3OFIO

I

LOCATION

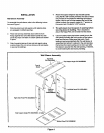

Thedesignis certifiedfor through-the-wallinstallationonly. Theinteriorportionsof theunit may besurroundedbya

closetwith clearancestocombustiblematerial held to 0" at sides,0" top and O" frontof the plenum.

Thegrille sideofthe unitmay beflush with orextendbeyondthe faceof theexteriorwall, butshouldnotberecessed

morethan two(2) inchesfrom theface ofthe buildingand shouldnotbe obstructedwithtrees, landscapematerials,

or buildingstructure.

Thereis nominimumclearancerequiredonlocatinga unittoaninteriorcornerofa building. If theunitis tobeenclos-

ed, provisionsshouldbemadeallowingaccessto theindoorsideof the unitfor changingfilters.and forinspection.At

least33" of unobstructedspaceshouldbe providedin front of the indoorside. whetherenclosedor noL to permit

removalof the coolingchassisshouldrepairsor inspectionbe required.

If this unit is installedin a residentialgarageit must be locatedor protectedtoavoidph_,sicaldamageby vehicles.

Thisunit must be installedso that no electricalcomponentsare exposedto water.

INSTALLATION

CAUTION:THESLEEVEIS NOTINTENDEDAS THESOLESUPPORTFORTHEUNIT. ANADDITIONALSUPPORTMUST

BE PROVIDEDNEARTHE RETURNOPENINGON THE UNIT FOR ADEQUATESUPPORT.THE USE OF VIBRATION

ISOLATIONMATERIALBETWEENTHE UNIT AND THE SUPPORTIS RECOMMENDED,

CAUTION:THIS UNITMUST BEINSTALLEDLEVELFORPROPERDRAINAGEOFTHE CHASSISBASEPANANDUNIT

DRAINPAN.

WITHOUTWALLSLEEVE

Measurethesizeofthe unitandprovideanopeningin anoutsidewall thatwill accepttheunit. Localordinancesmay

require a steel lintel to supportthe wall abovethe opening. Thisopeningmust besquare in all corners.

Positionthe unitsothat the grilleson the outsidefaceofthe unit areflush or extendbeyondthe faceofthe exterior

wall,but notrecessedmorethantwo (2) inchesfromthefaceof the building.PROVIOEA SUPPORTUNDERTHE UNIT

INSIDETHE BUILDING.Makesure thatthe insidesupportdoesnot blockthereturnair. The unitshouldbe installed

level.

Sealthe spacebetweentheunit and the buildingopeningusinga non-hardeningcaulkingcompound.Theseal must

beweather-tightto prevententranceof moistureandwater intothe building.Make sure the drainholesin the base

are notpluggedwith caulking.

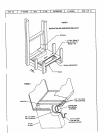

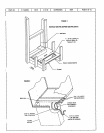

WITH WALL SLEEVE

Seethe installationinstructionspacked with Ihe wall sleeveto assembleand mountin a wall. Make sure that the

gasketsattachedtothe sleeveare notdamaged.Assurethat the unitis completelyseatedagainstthegasketsonthe

wall sleeve.

Sealspacebetweenwall sleeveand buildingopeningusingnon-hardeningcaulkingcompound.Thisseal must be

watertight.

CONDENSATEDRAIN

Install the plasticdraintube(furnished)overthe5/8" O.O. fittingwelded tothe condensatepan. Connectotherend

of thedraintubeto trappeddrain line(See Figure2). Theplasticdrain connectionto thechassisbaseis providedso

thatit may bedisconnectedfromthepermanentdrain tubingin the baseof unitin theeventit becomesnecessaryto

removethe chassisassembly.

L

The drain line should pitch gradualtydownwardat least 1" per 10 footof horizontalrun to the opendrain.

Be certainthat the plasticdrain tubing hastree drainageand is notcrimpedor flattenedat anybend.