Page 33

EL296UHE DIRECT VENT APPLICATION

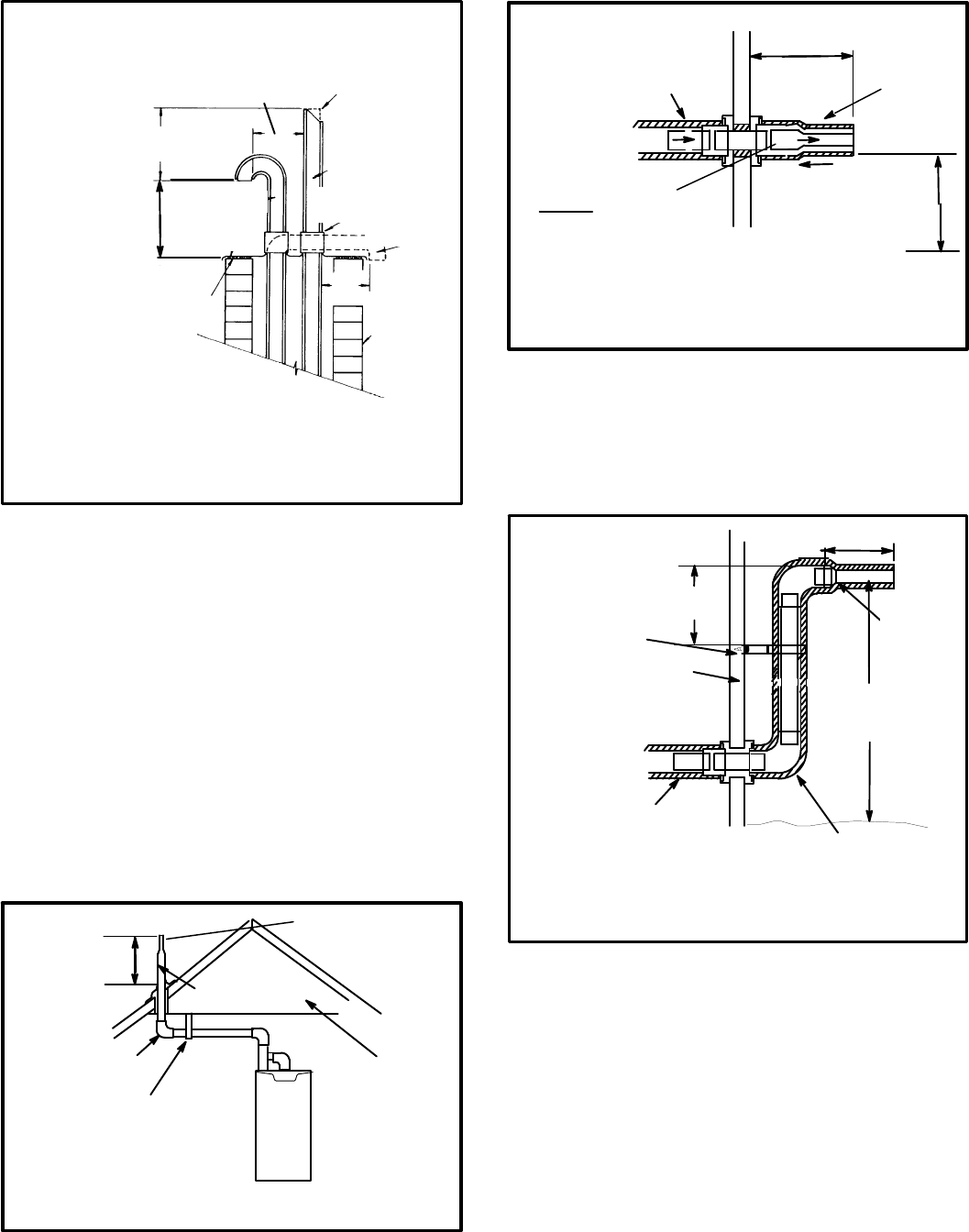

USING EXISTING CHIMNEY

NOTE - Do not discharge exhaust gases directly into any chimney or vent stack. If ver

tical discharge through an existing unused chimney or stack is required, insert piping

inside chimney until the pipe open end is above top of chimney and terminate as illus

trated. In any exterior portion of chimney, the exhaust vent must be insulated.

FIGURE 46

3” - 8”

(76MM-

203MM)

STRAIGHT-CUT OR

ANGLE-CUT IN DIRECTION

OF ROOF SLOPE *

EXHAUST VENT

1/2” (13MM)

WEATHERPROOF

INSULATION

SHOULDER OF FITTINGS

PROVIDE SUPPORT

OF PIPE ON TOP PLATE

ALTERNATE

INTAKE PIPE

INTAKE PIPE

INSULATION (optional)

EXTERIOR

PORTION OF

CHIMNEY

INSULATE

TO FORM

SEAL

SHEET

METAL TOP

PLATE

*SIZE TERMINATION

PIPE PER TABLE 8.

Minimum 12” (305MM)

above chimney top

plate or average snow

accumulation

8” - 12”

(203MM - 305MM)

3”-8”

(76MM-203MM)

Details of Exhaust Piping Terminations for Non‐Direct

Vent Applications

Exhaust pipes may be routed either horizontally through an

outside wall or vertically through the roof. In attic or closet

installations, vertical termination through the roof is pre

ferred. Figures 47 through 50 show typical terminations.

1 - Exhaust piping must terminate straight out or up as

shown. The termination pipe must be sized as listed in

table 8.The specified pipe size ensures proper veloc

ity required to move the exhaust gases away from the

building.

2 - On field supplied terminations for side wall exit, ex

haust piping may extend a maximum of 12 inches

(305MM) for 2” PVC and 20 inches (508MM) for 3”

(76MM) PVC beyond the outside wall. See figure 48.

FIGURE 47

NON-DIRECT VENT ROOF TERMINATION KIT

(15F75 or 44J41)

UNCONDITIONED

ATTIC SPACE

3” (76MM) OR

2” (51MM) PVC

PROVIDE SUPPORT

FOR EXHAUST LINES

12” (305MM)

ABOVE AVE.

SNOW

ACCUMULATION

SIZE TERMINATION

PIPE PER TABLE 8.

1/2” (13MM) FOAM

INSULATION

FIGURE 48

1/2” (13MM) ARMAFLEX

INSULATION IN

UNCONDITIONED SPACE

PVC REDUCER

1/2” (13MM)

ARMAFLEX

INSULATION

NON-DIRECT VENT FIELD SUPPLIED WALL TERMINATION OR

(15F74) WALL TERMINATION KIT

SIZE TERMINATION

PIPE PER TABLE 8.

FIELD-PROVIDED

REDUCER MAY

BE REQUIRED TO

ADAPT LARGER

VENT PIPE SIZE

TO TERMINATION

12” MIN.

(305MM)

Above Grade or

average snow

accumulation

12” (305MM) MAX. for 2” (51MM)

20” (508MM) MAX. for 3” (76MM)

3 - If exhaust piping must be run up a side wall to position

above snow accumulation or other obstructions, pip

ing must be supported every 24 inches (610MM) as

shown in figure 49. When exhaust piping must be run

up an outside wall, any reduction in exhaust pipe size

must be done after the final elbow.

FIGURE 49

12” (305MM)

ABOVE GRADE OR

AVERAGE SNOW

ACCUMULATION

UNCONDITIONED

SPACE

1/2” (13MM) FOAM

INSULATION

1/2” (13MM) FOAM

INSULATION IN

UNCONDITIONED

SPACE

*WALL SUPPORT

OUTSIDE WALL

SIZE TER

MINATION

PIPE PER

TABLE 8.

FIELD-PROVIDED

REDUCER MAY BE

REQUIRED TO

ADAPT LARGER

VENT PIPE SIZE TO

TERMINATION

*Use wall support every 24” (610). Use two supports if extension is

greater than 24” but less than 48”.

12” (305MM) MAX. for 2” (51MM)

20” (508MM) MAX. for 3” (76MM)

NON-DIRECT VENT FIELD SUPPLIED WALL TERMINATION

EXTENDED OR (15F74) WALL TERMINATION VENT PIPE

EXTENDED

6” (152MM)

Max