Page 14

CAUTION

Solvent cements for plastic pipe are flammable liq

uids and should be kept away from all sources of

ignition. Do not use excessive amounts of solvent

cement when making joints. Good ventilation should

be maintained to reduce fire hazard and to minimize

breathing of solvent vapors. Avoid contact of ce

ment with skin and eyes.

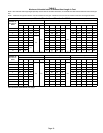

TABLE 2

PIPING AND FITTINGS SPECIFICATIONS

Schedule 40 PVC (Pipe) D1785

Schedule 40 PVC (Cellular Core Pipe) F891

Schedule 40 PVC (Fittings) D2466

Schedule 40 CPVC (Pipe) F441

Schedule 40 CPVC (Fittings) F438

SDR-21 PVC or SDR-26 PVC (Pipe) D2241

SDR-21 CPVC or SDR-26 CPVC (Pipe) F442

Schedule 40 ABS Cellular Core DWV (Pipe) F628

Schedule 40 ABS (Pipe) D1527

Schedule 40 ABS (Fittings) D2468

ABS-DWV (Drain Waste & Vent)

(Pipe & Fittings)

D2661

PVC-DWV (Drain Waste & Vent)

Pipe & Fittings)

D2665

PRIMER & SOLVENT CEMENT

ASTM

SPECIFICATION

PVC & CPVC Primer F656

PVC Solvent Cement D2564

CPVC Solvent Cement F493

ABS Solvent Cement D2235

PVC/CPVC/ABS All Purpose Cement For

Fittings & Pipe of the same material

D2564, D2235, F493

ABS to PVC or CPVC Transition Solvent

Cement

D3138

CANADA PIPE & FITTING & SOLVENT

CEMENT

MARKING

PVC & CPVC Pipe and Fittings

ULCS636

PVC & CPVC Solvent Cement

ABS to PVC or CPVC Transition Cement

IMPORTANT

EL296UHE exhaust and intake connections are

made of PVC. Use PVC primer and solvent cement

when using PVC vent pipe. When using ABS vent

pipe, use transitional solvent cement to make con

nections to the PVC fittings in the unit.

Use PVC primer and solvent cement or ABS solvent cement

meeting ASTM specifications, refer to Table 2. As an alter

nate, use all purpose cement, to bond ABS, PVC, or CPVC

pipe when using fittings and pipe made of the same materi

als. Use transition solvent cement when bonding ABS to ei

ther PVC or CPVC.

Low temperature solvent cement is recommended during

installation in cooler weather. Metal or plastic strapping may

be used for vent pipe hangers. Uniformly apply a liberal coat

of PVC primer for PVC or use a clean dry cloth for ABS to

clean inside socket surface of fitting and male end of pipe to

depth of fitting socket.

Canadian Applications Only - Pipe, fittings, primer

and solvent cement used to vent (exhaust) this ap

pliance must be certified to ULC S636 and supplied by a

single manufacturer as part of an approved vent (ex

haust) system. In addition, the first three feet of vent

pipe from the furnace flue collar must be accessible for

inspection.

Joint Cementing Procedure

All cementing of joints should be done according to the

specifications outlined in ASTM D 2855.

DANGER

DANGER OF EXPLOSION!

Fumes from PVC glue may ignite during system

check. Allow fumes to dissipate for at least 5 minutes

before placing unit into operation.

1 - Measure and cut vent pipe to desired length.

2 - Debur and chamfer end of pipe, removing any ridges

or rough edges. If end is not chamfered, edge of pipe

may remove cement from fitting socket and result in a

leaking joint.

NOTE - Check the inside of vent pipe thoroughly for

any obstruction that may alter furnace operation.

3 - Clean and dry surfaces to be joined.

4 - Test fit joint and mark depth of fitting on outside of pipe.

5 - Uniformly apply a liberal coat of PVC primer for PVC or

use a clean dry cloth for ABS to clean inside socket

surface of fitting and male end of pipe to depth of fitting

socket.

NOTE - Time is critical at this stage. Do not allow prim

er to dry before applying cement.

6 - Promptly apply solvent cement to end of pipe and in

side socket surface of fitting. Cement should be ap

plied lightly but uniformly to inside of socket. Take

care to keep excess cement out of socket. Apply sec

ond coat to end of pipe.

7 - Immediately after applying last coat of cement to pipe,

and while both inside socket surface and end of pipe

are wet with cement, forcefully insert end of pipe into

socket until it bottoms out. Turn PVC pipe 1/4 turn dur

ing assembly (but not after pipe is fully inserted) to dis

tribute cement evenly. DO NOT turn ABS or cellular

core pipe.

NOTE - Assembly should be completed within 20 sec

onds after last application of cement. Hammer blows

should not be used when inserting pipe.