Page 24

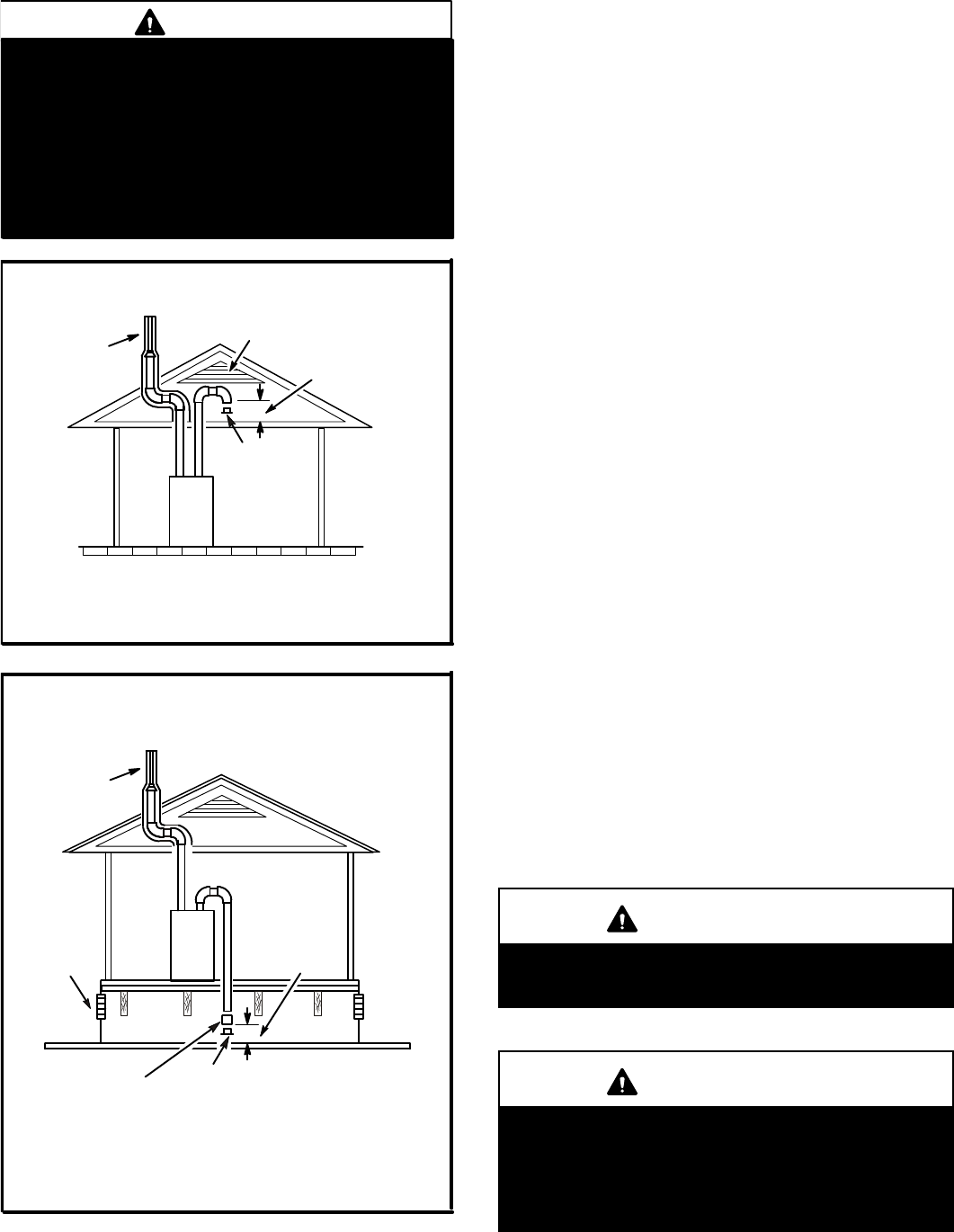

CAUTION

If this unit is being installed in an application with

combustion air coming in from a space serviced by

an exhaust fan, power exhaust fan, or other device

which may create a negative pressure in the space,

take care when sizing the inlet air opening. The in

let air opening must be sized to accommodate the

maximum volume of exhausted air as well as the

maximum volume of combustion air required for

all gas appliances serviced by this space.

FIGURE 28

EQUIPMENT IN CONFINED SPACE

(Inlet Air from Ventilated Attic and Outlet Air to Outside)

NOTE-The inlet and outlet air openings shall each have a free area

of at least one square inch per 4,000 Btu (645mm

2

per 1.17kW) per

hour of the total input rating of all equipment in the enclosure.

Ventilation Louvers

Inlet Air

(Minimum

12 in.(305mm) Abov

e

attic floor)

Roof Terminated

Exhaust Pipe

Furnace

*Intake Debris

Screen

(Provided)

* See table 6 for maximum vent lengths

FIGURE 29

NOTE-The inlet and outlet air openings shall each have a free area

of at least one square inch per 4,000 Btu (645mm

2

per 1.17kW) per

hour of the total input rating of all equipment in the enclosure.

EQUIPMENT IN CONFINED SPACE

(Inlet Air from Ventilated Crawlspace and Outlet Air to Outside)

Roof Terminated

Exhaust Pipe

Furnace

Ventilation

Louvers

(Crawl space)

*Intake Debris Screen Provided)

Inlet Air

(Minimum

12 in.(305mm)

Above crawl

space floor)

Coupling or

3 in. to 2 in.

Transition

(Field Provided)

* See table 6 for maximum vent lengths

General Guidelines for Vent Terminations

In Non‐Direct Vent applications, combustion air is taken

from indoors or ventilated attic or crawlspace and the flue

gases are discharged to the outdoors. The EL296UHE is

then classified as a non‐direct vent, Category IV gas fur

nace.

In Direct Vent applications, combustion air is taken from

outdoors and the flue gases are discharged to the out

doors. The EL296UHE is then classified as a direct vent,

Category IV gas furnace.

In both Non‐Direct Vent and Direct Vent applications, the

vent termination is limited by local building codes. In the

absence of local codes, refer to the current National Fuel

Gas Code ANSI Z223-1/NFPA 54 in U.S.A., and current

CSA-B149 Natural Gas and Propane Installation Codes in

Canada for details.

Position termination according to location given in figure 30

or 31. In addition, position termination so it is free from any

obstructions and 12” above the average snow accumula

tion.

At vent termination, care must be taken to maintain

protective coatings over building materials (prolonged

exposure to exhaust condensate can destroy protective

coatings). It is recommended that the exhaust outlet not be

located within 6 feet (1.8m) of a condensing unit because

the condensate can damage the painted coating.

NOTE - See table 7 for maximum allowed exhaust pipe

length without insulation in unconditioned space during

winter design temperatures below 32°F (0°C). If required

exhaust pipe should be insulated with 1/2” (13mm) Arma

flex or equivalent. In extreme cold climate areas, 3/4”

(19mm) Armaflex or equivalent may be necessary. Insula

tion on outside runs of exhaust pipe must be painted or

wrapped to protect insulation from deterioration. Exhaust

pipe insulation may not be necessary in some specific ap

plications.

IMPORTANT

Do not use screens or perforated metal in exhaust

terminations. Doing so will cause freeze-ups and

may block the terminations.

IMPORTANT

For Canadian Installations Only:

In accordance to CSA International B149 installation

codes, the minimum allowed distance between the

combustion air intake inlet and the exhaust outlet of

other appliances shall not be less than 12 inches

(305mm).