57

WTC 600 LP / MP MAINTENANCE

Service Handbook 08.2004

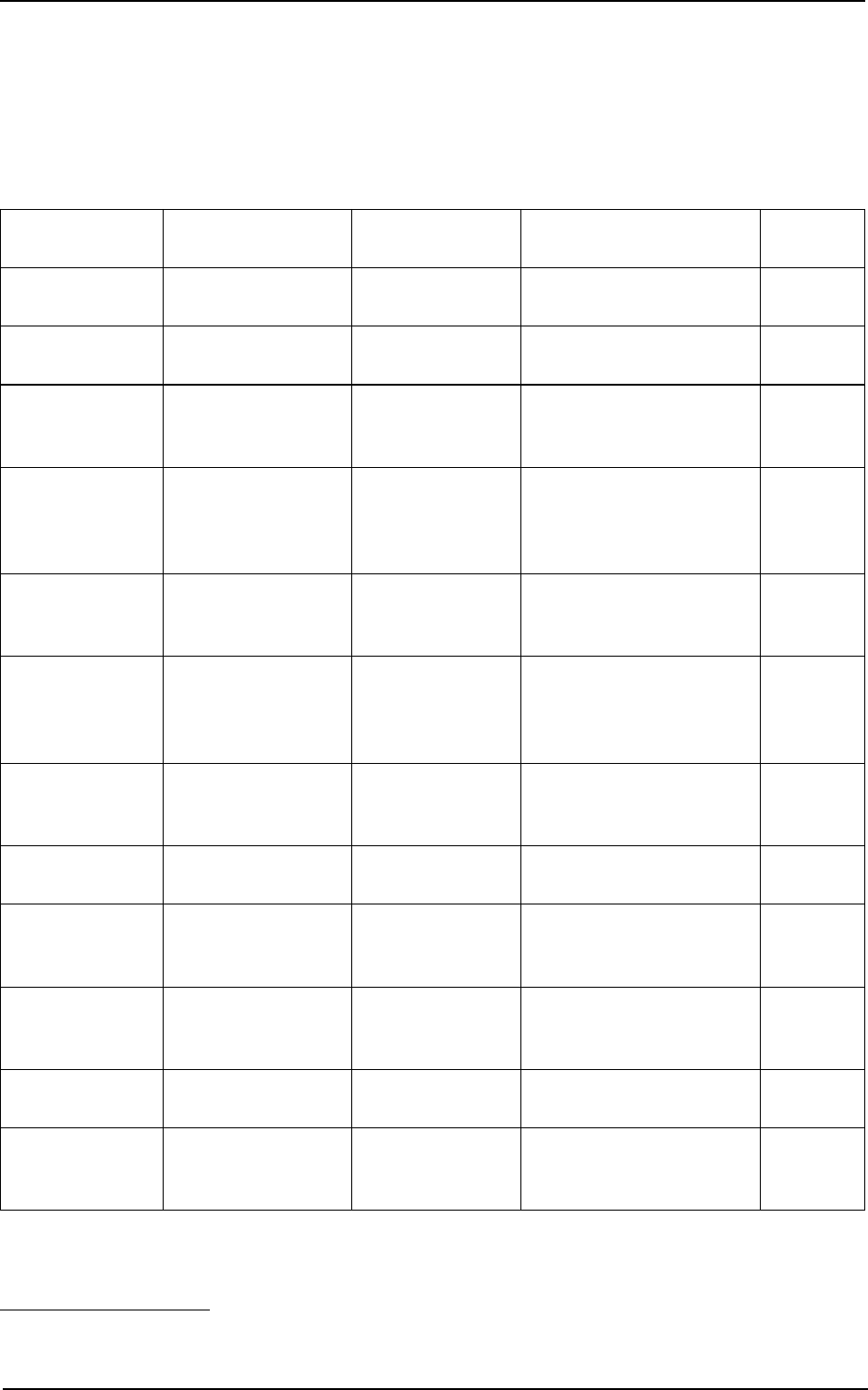

4.5.2 Malfunction Indication at the Operating Panel

The control system detects operational malfunctions only while in operation operating mode;

these are indicated on the display. The occurrence of an error usually leads to the complete

system being switched off (production is interrupted).

Indication Malfunction Cause Corrective Action Chap./

Fig.

Motor/ Metering containe Fill up 3.2

hard water empty

Lack of pressure PI station gene- No water Establish the flow of

rates no pressure available untreated water again

Air in the pump Bleed the pump; connect

pump directly in canal,

run for 30 sec.

Suction height too Ensure supply pressure

high, pump is not to the pump (mains

self-priming supply, submerged

pump, ... )

Supply pressure of Flow rate through see 4.5.4

the reverse preliminary filter

osmosis too low too low

Differential Filter soiled Replace filter cartridge 4.1

pressure of the

preliminary filter

>>1 bar

Pressure switch Replace pressure 2.2,

defective switch (pay attention to Pos. 4.9

setting)

Flow rate in sand Filter clogged Initiate backwashing 3.4.2

filter too low

Conductance Permeate Yield too high Increase flow of 3.4.3.7

value conductance value concentrate

exceeded too high

Very high salt Check cause;

1)

content in notify sales dept.

untreated water

Defective seal or Replace parts; switch off ETL

membrane system, if required

Conductance Calibrate again; ETL, SLP

value probe replace if required

defective

Table 29

1)

See untreated water analysis, operational start-up record