45

WTC 600 LP / MP MAINTENANCE

Service Handbook 08.2004

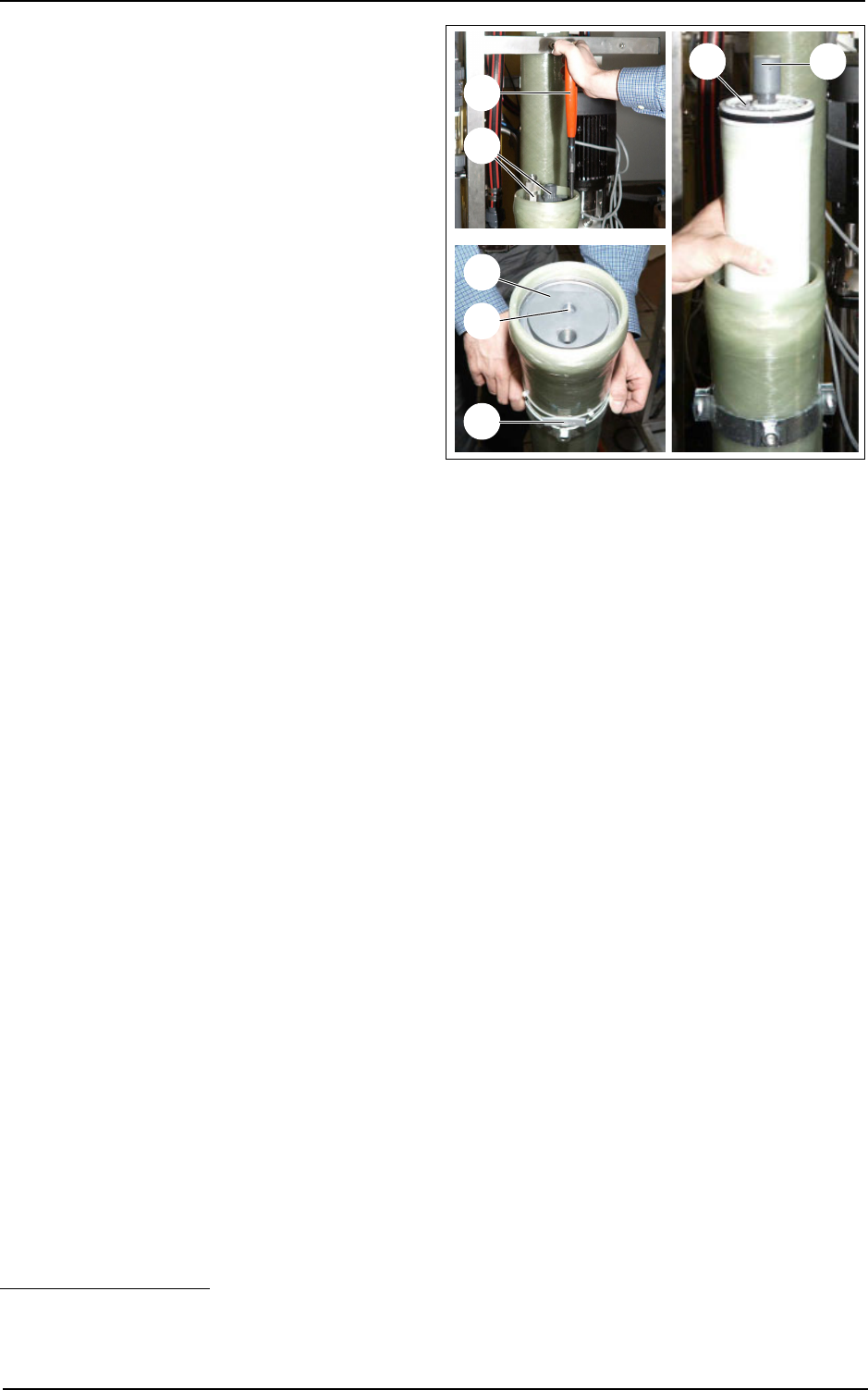

- Apply Propandiol

1)

to the rubber seals.

- Insert a new filter (19/7) at the supply

opening (end without seal first!).

- Attach all adapters.

- Insert lid (19/4) in such a manner that the

threads of the openings are flush with the

nuts of the clamp (19/5).

- Install securing rings and screw in

connections.

- Fasten module to frame and connect pipe

lines.

- Flush the equipment for 10 minutes

(3.4.3.7).

- Switch to the operation operating mode:

- The equipment values must correspond with

those of the initial start-up.

Figure 19 Assembly and disassembly of the RO

filter

4.4 Cleaning in Case of Malfunction

The following measured variables or their change from the original values (cf. operating

certificate) are indicators for the need for cleaning or disinfecting the system.

The WTC 600 service kit (2.901.044.0) is intended for cleaning the WTC 600. Apart from the

cleaning chemicals and a wet-dry vacuum, it contains all the equipment needed for cleaning and

conserving the WTC 600 LP and MP.

The cleaning chemicals must be ordered separately.

The system should be cleaned if the following differences occur compared to the initial startup

- The drinking water flow drops by 200l/h at the same pressure

- The conductivity doubles at the same pressure and temperature

- The differential pressure between the pump pressure and concentrate pressure increases

by more than 2 bar.

Alkali cleaning with RM MCT 511 first, then acid cleaning with RM MCT 103.

Only disinfect if cleaning is unsuccessful.

1)

Propandiol: Item No. 6.290-910.0

2

1

4

5

67

3

NOTE

NOTE