10

classic HE - Installation & Servicing

GENERAL

Minimum Requirements

Note. The pump manufacturers minimum

requirements must be complied with.

System

return

Connections

to boiler

Inverted cold

feed entry

System

flow to

pump

150 (6")

Max

15mm

Cold

feed

450 (17

3

/

4

")

Mimimum

450 (17

3

/

4

")

Mimimum

22mm

Open vent

Feed / expansion

cistern

Water

level

(cold)

cla7840

Surge

arrester

75 (3)

Min.

450

(17

3

/

4

")

Min.

200

(8)

Min.

Highest

point of

flow or

return

150

(6)

Max

Max. practical

length

To pump

Cold

water

level

Feed / expansion

cistern

75 (3) Min.

Flow

Return

22 (3/4)

Open vent

cla7839

All dimensions in mm (in.). N.B. Imperial dimensions are approximate

4

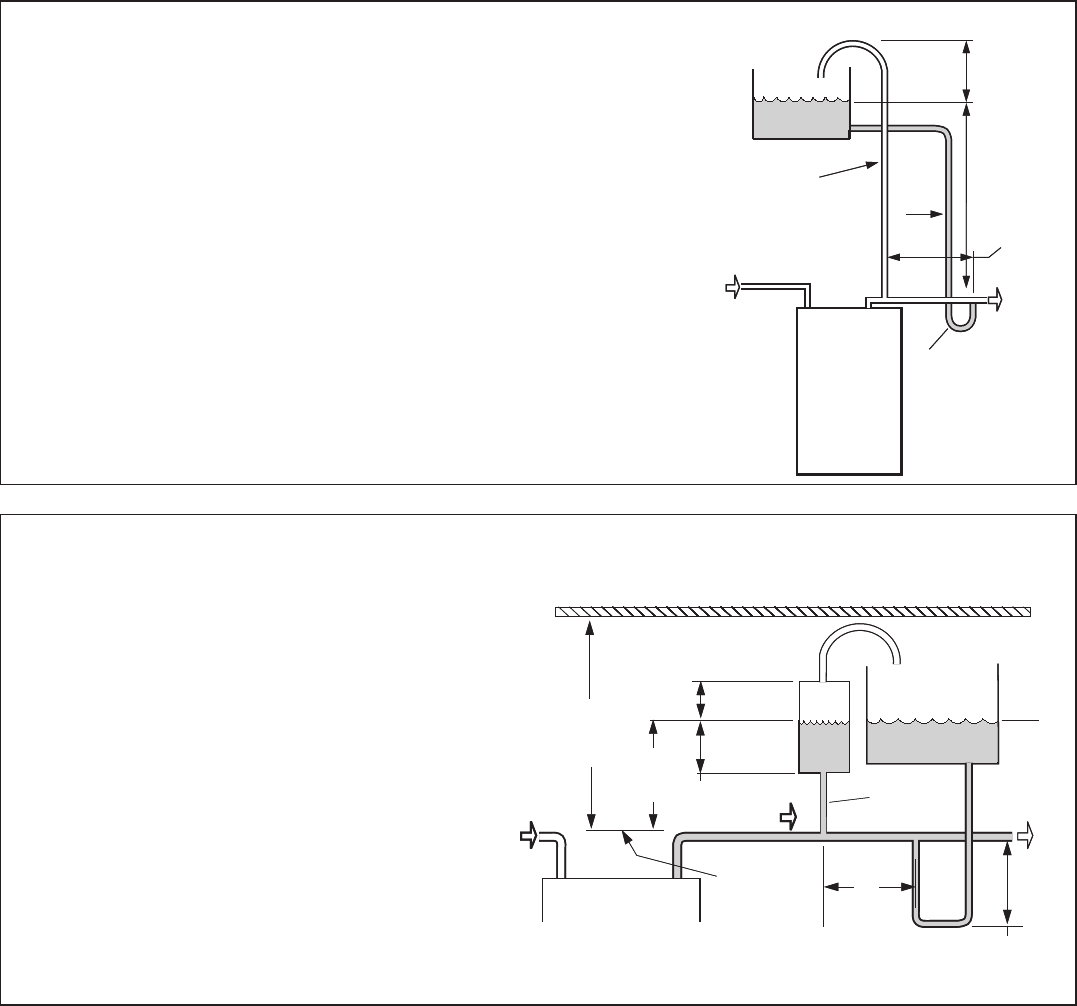

LOW HEAD INSTALLATIONS

The system should be vented directly off the boiler flow pipe, as close to the

boiler as possible. The cold feed entry should be inverted and MUST be

positioned between the pump and the vent, and not more than 150mm (6")

away from the vent connection.

There should be a minimum height - 450mm (17

3

/4") - of open vent above

cistern water level. If this is impossible refer below.

The vertical distance between the highest point of the system and the feed/

expansion cistern water level MUST not be less than 450mm (17

3

/4").

The pump MUST be fitted on the flow side of the boiler.

A suitable pump is a domestic circulator capable of providing an 11

o

C (20

o

F)

temperature differential (e.g. Grundfos UPS 15/50 or equivalent). The vertical

distance between the pump and feed/expansion cistern MUST comply with

the pump manufacturers minimum requirements to avoid cavitation. Should

these conditions not apply, either lower the pump position or raise the cistern

above the minimum requirement specified by Ideal Stelrad Group.

Note. A cold water feed must be available back to the boiler, when all

automatic valves are in the closed position (refer to BS. 6798) and when close

coupled the feed must not be in a vertical leg.

The classic HE range of boilers can be installed in low head

situations by fitting a 'surge arrester' in the expansion pipe as

shown.

The following conditions MUST be observed:

1. The surge arrester must be at least 42mm in diameter x

150mm long, thus ensuring a MINIMUM air gap and a

MINIMUM depth of water below the static water level (cold)

of 75mm.

2. The static water level (cold) must be at least 200mm

above the top of the horizontal flow pipe, fitted as shown.

The vent connection MUST NOT be made immediately off

the top of the boiler, as venting is made less efficient.

3. The maximum practical length of 15mm cold feed pipe

should be used in order to reduce the effective volume of

system water expanding into the feed/expansion cistern to

a minimum.

3

OPEN VENT SYSTEM REQUIREMENTS - FULLY PUMPED

Central heating systems controls should be installed to

ensure the boiler is switched off when there is no demand for

heating or hot water.

When thermostatic radiator valves are used, the space heating

temperature control over a living / dining area or hallway having

a heating requirement of at least 10% of the boiler heat output

should be achieved using a room thermostat, whilst other

rooms are individually controlled by thermostatic radiator

valves. However, if the system employs thermostatic radiator

valves on all radiators, or two port valves without end switches,

then a bypass circuit must be fitted with an automatic bypass

valve to ensure a flow of water should all valves be in the

closed position.

ELECTRICAL SUPPLY

WARNING. The appliance MUST be efficiently earthed.

Wiring external to the appliance MUST be in accordance with

the current I.E.E. (BS.7671) Wiring Regulations and any local

regulations which apply. For Ireland reference should be

made to the current ETCI rules for electrical installations.

The point of connection to the mains should be readily accessible

and adjacent to the boiler, except that for bathroom installations; the

point of connection to the mains MUST be situated outside of the

bathroom.

Note.

Where a room sealed appliance is installed in a room containing

a bath or shower then the appliance and any electrical switch or

appliance control utilising mains electricity should be so situated

that it cannot be touched by a person using the bath or shower.

See Frame 41 for details.

CONDENSATE DRAIN Refer to Frames 38, 39 and 40

A condensate drain siphon is provided on the boiler. This drain

must be connected to a drainage point on site. All pipework and

fittings in the condensate drainage system MUST be made of

plastic- no other materials may be used.

IMPORTANT.

Any external runs must be insulated.

The drain outlet on the boiler is standard 21.5mm (3/4") overflow

pipe.

201850-6.pmd 21/02/2008, 12:5710