15

Boilers intended to be connected to an existing boiler or boiler system shall:

1. Be capable of being installed without interfering with the normal delivery of heated water from the original boiler to the

radiation system.

2. Be capable of being installed to operate as intended without affecting the operation of the electrical and mechanical safety

controls of the original boiler.

3. Provide, upon completion of the installation, for a change over from one fuel to the other without requiring the manual

adjustment of any controls or components other than the thermostats.

4. Be compatible with the operation of a service water-heating coil within the original boiler without bypassing the operation

of the solid-fuel boiler.

5. Have provision for preventing, or adequate water capacity within the boiler to prevent, damage to the boiler from loss of

circulation due to electrical power failure.

6. Be capable of being installed without changing the function of the control or rewiring of the original boiler. A wiring

interconnection is permitted. The electrical system of both boilers shall be powered from a single branch circuit without

exception.

(CAN/CSA-B366.1-M91)

7. Pertaining to CAN/CSA- B365-01, Have a clearly labelled device, located at each entrance to the boiler area, which can

be thrown to discontinue operation to the feed system.

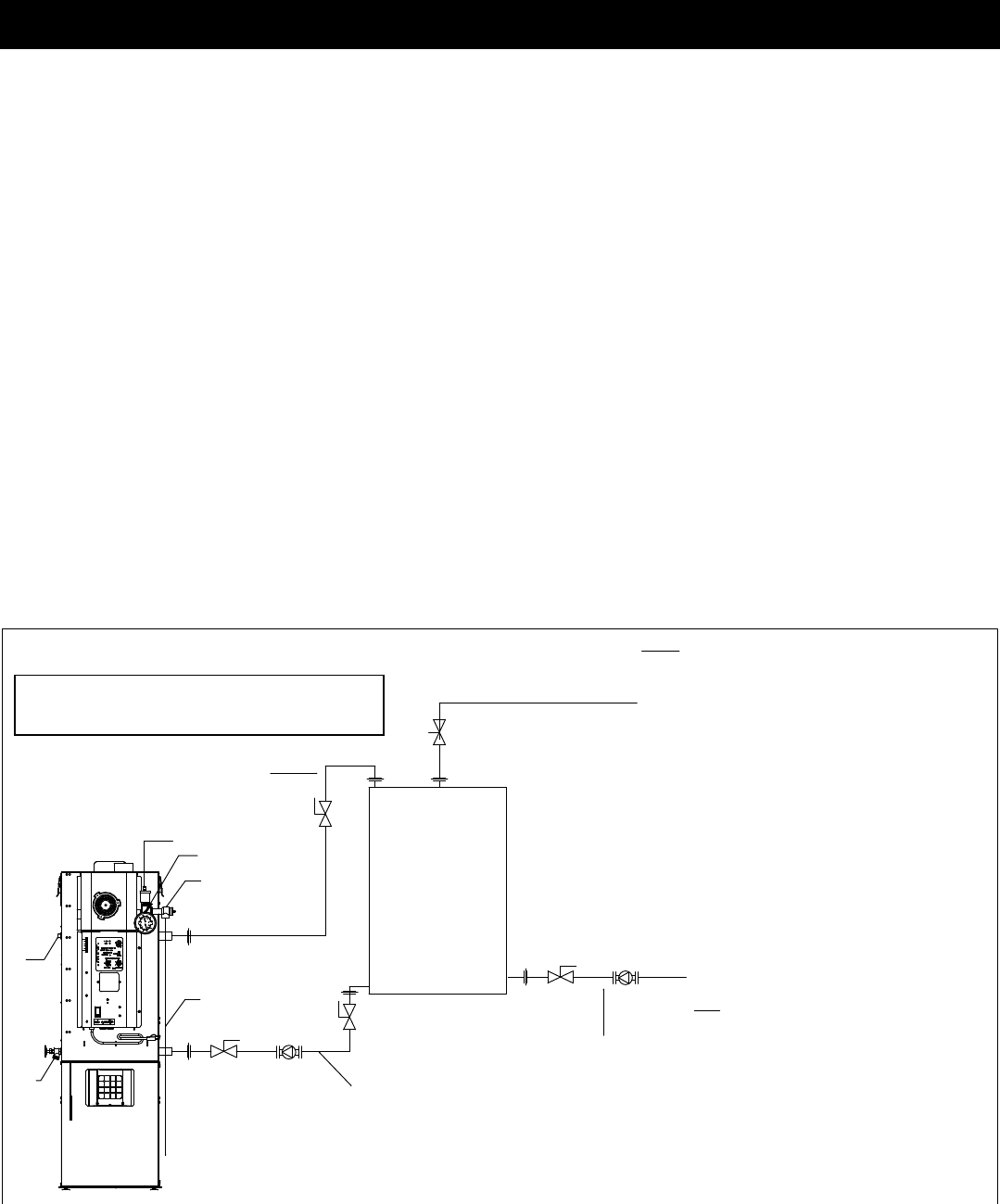

EXAMPLE OF PIPING WITH AN INDEPENDENT CIRCULATOR SYSTEM

CONNECTED TO AN EXISTING OPERATIONAL BOILER

* BOILER DRAIN, 3/4" NPT MALE X 3/4" HOSE

* 3/4" NPT MALE PLUG

RETURN 3/4"

SYSTEM SUPPLY

* AUTOMATIC AIR VENT

* TEMP/PRESSURE

GAUGE

* PRESSURE RELIEF VALVE

PIPE TO WITHIN

6" OF THE

FLOOR OR A

FLOOR DRAIN

UNION

OUT

UNION

SHUT-OFF VALVE

EXISTING

BOILER

UNION

NOTE: NOT SHOWN IN THIS DRAWING ARE ALL OF THE

ASSOCIATED PIPING AND CONTROLS THAT SHOULD

ALREADY BE IN PLACE WITH THE EXISTING BOILER

SYSTEM. FOR EXAMPLE, THE EXPANSION TANK, THE

COLD WATER SUPPLY , AIR REMOVAL SYSTEM ETC... IT IS

EXTREMELY IMPORTANT THAT THIS BOILER BE

INSTALLED BY A QUALIFIED INSTALLER AND THAT ALL

EXISTING CONTROLS AND SAFETY DEVICES ARE

VERIFIED AS OPERATIONAL.

* ITEMS SUPPLIED

NOTE: ALWAYS REFER TO THE INDIVIDUAL COMPONENTS

RECOMMENDED INSTALLATION INSTRUCTIONS FOR THE PROPER

MOUNTING POSITION AND LOCATION WITHIN THE PIPING SYSTEM.

CIRCULATOR

SHUT-OFF

VALVE

SHUT-OFF

VALVE

UNION

SUPPLY 3/4"

SYSTEM RETURN

UNION

IN

BALANCING VALVE

SHUT-OFF VALVE

UNION

CIRCULATOR

NOTICE: When installing with the Atmospheric Conversion, all of the

pressurized system components shown are not necessary. Air vents or

bleeders should be removed from the plumbing system to prevent air

from entering the lines. Control dipswitch #6 must be “ON”.

NOTE: Cold return water temperature (Sustained temperatures below 140 degrees

Fahrenheit) will lead to condensation or moisture in the firebox. This moisture can

lead to creosote formation. To help minimize moisture and creosote, it is strongly

recommended that some method of temperature balance is incorporated into the

return system.

Anti-freeze and/or boiler water treatment:

There is no restriction on the type of commercial antifreeze used. When lling the boiler water system, it is recommended

that some form of boiler water treatment be used.