10

Venting

Use only 3” pellet vent pipe to vent your pellet boiler.

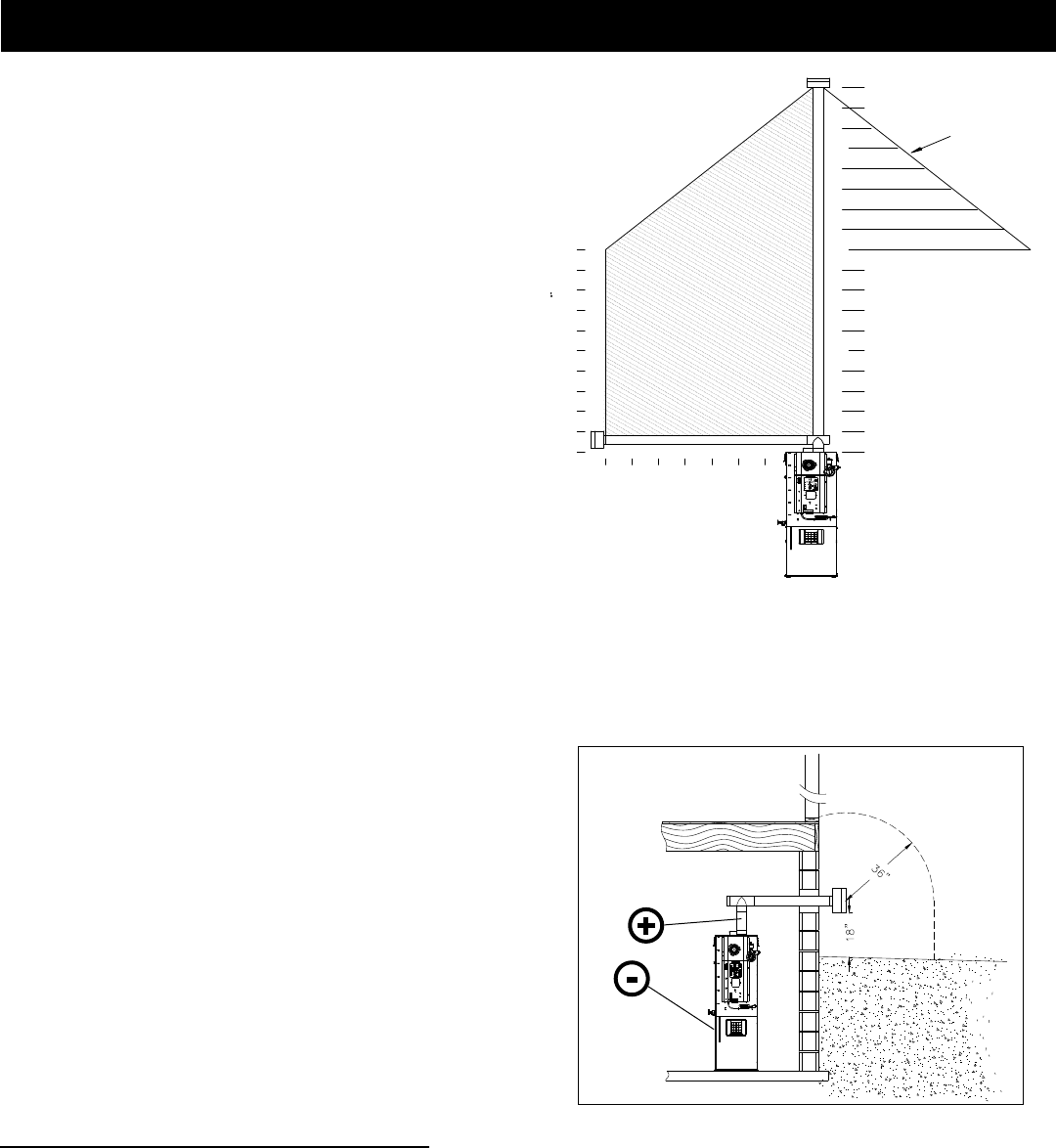

A combustion blower is used to extract the combustion

gases from the rebox. This creates a negative pressure in

the rebox and a positive pressure in the venting system as

shown in Fig. 4. The longer the vent pipe and more elbows

used in the system, the greater the ow resistance, and the

greater the chance for creosote accumulation. Because of

these facts we recommend using as few elbows as possible

and 18 feet or less of vent pipe. The maximum horizontal

run should never exceed 8 feet.

Be sure to use wall and ceiling pass through ttings

(which are approved for pellet vent pipe ) when going

through combustible materials. Be sure to use a starting

collar to attach the venting system to the stove. The starting

collar must be sealed to the stove ue collar with high

temp silicone caulking or aluminum tape, and screwed

into the units’ ue collar in a minimum of three (3) places.

Due to low exhaust temperatures, increasing the diameter

of the venting or exceeding the recommendations of the

venting graph, is strongly discouraged.

Vent Pipe

3” pellet vent pipe (also known as “PL” vent) is constructed

of two layers with air space between the layers. This air space

acts as an insulator and reduces the outside surface temperature

to allow a minimum clearance to combustibles as low as 1

inch. In Canada the minimum clearance to combustibles is

3 inches. Check with the venting manufacturer to be certain

of specied clearances.

The sections of pipe lock together to form an air tight seal

in most cases; however, in some cases a perfect seal is not

achieved. For this reason and the fact that the unit operates

with a positive vent pressure, we specify that all joints

within the structure should be secured with at least 3

screws, and sealed with silicone caulking.

Fig. 3

Creosote - Formation and Need for Removal - When wood is burned slowly, it produces tar and other organic vapors,

which combine with expelled moisture to form creosote. The creosote vapors condense in the relatively cool chimney ue

of a slow-burning re. As a result, creosote residue accumulates on the ue lining. When ignited, this creosote makes an

extremely hot re. The pellet vent pipe should be inspected at least twice monthly during the heating season to determine

if a creosote buildup has occurred. If creosote has accumulated it should be removed to reduce the risk of a chimney re.

Guidance on minimizing creosote formation and the need for periodic creosote removal: The chimney should be inspected

during the heating season to determine if a creosote build-up has occurred. If a signicant layer of creosote has accumulated,

1/8” (3mm) or more, it should be removed to reduce the risk of a chimney re.

NOTE:Use only 3” diameter Pellet venting system.

Be sure to inspect and clean exhaust venting system

frequently.

10

Total Lineal Feet Combined

Should Not Exceed 18' as

measured from the outlet.

0

2

6

4

8

68 4 2

5

Altitude in Thousands of Feet

10

Maximum Horizontal Run 8'

10

5

7

6

9

8

18

15

4

The Total Lineal Feet

Decreases as the

Altitude Increases

Fig. 4

-

+