38

ENVISION RESIDENTIAL INSTALLATION MANUAL

Troubleshooting

Standard Microprocessor Controls

To check the unit control board for proper operation:

1) Disconnect thermostat wires at the control board.

2) Jumper the desired test input (Y1, Y2, W, O or G) to the R terminal to simulate a thermostat signal.

3) If control functions properly:

• Check for thermostat and fi eld control wiring (use the diagnostic inputs mode).

4) If control responds improperly:

• Ensure that component being controlled is functioning (compressor, blower, reversing valve, etc.).

• Ensure that wiring from control to the component is functioning (refer to the LED Defi nition table below and use the

diagnostic outputs mode).

• If steps above check properly, replace unit control.

Refrigerant Systems

To maintain sealed circuit integrity, do not install service gauges unless unit operation appears abnormal. Compare the

change in temperature on the air side as well as the water side to the tables on pages 35-36. If the unit’s performance is not

within the ranges listed, and the airfl ow and water fl ow are known to be correct, gauges should then be installed and super-

heat and subcooling numbers calculated. If superheat and subcooling are outside recommended ranges, an adjustment to

the refrigerant charge may be necessary.

Note:

Refrigerant tests must be made with desuperheater turned “OFF”.

Verify that air and water fl ow rates are at proper

levels before servicing the refrigerant circuit.

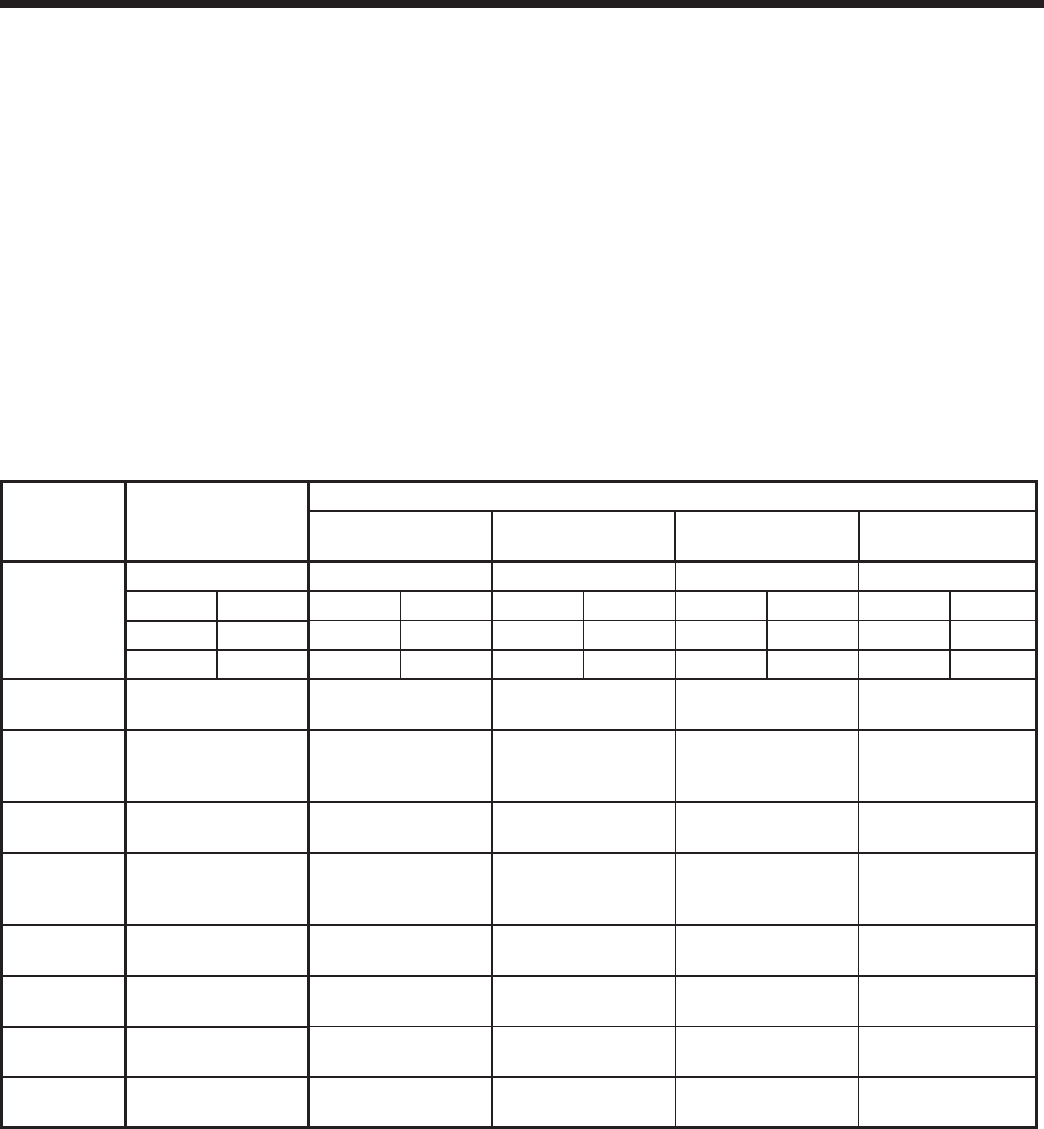

LED

NORMAL

DISPLAY MODE

DIAGNOSTIC MODES

CURRENT

FAULT STATUS

INPUTS OUTPUTS 1 OUTPUTS 2

Field Selection DIPS

SW2- 1 On SW2- 1 Off SW2- 1 NA SW2- 1 NA SW2- 1 NA

SW2- 6 On SW2- 6 On SW2- 6 Off SW2- 6 On SW2- 6 Off

SW2- 7 On SW2- 7 On SW2- 7 On SW2- 7 Off SW2- 7 Off

Drain

Drain Pan Overfl ow

Lockout

Drain Pan Overfl ow Y1

Compressor

(On or Low)

Blower

Low

Water Flow

FP Thermistor (Loop

<15º F, Well<30ºF)

Lockout

FP Thermistor (Loop

<15º F, Well<30ºF)

Y2

Compressor

(On or High)

Blower

Medium

High

Pressure

High Pressure >600

PSI Lockout

High Pressure >600 O Reversing Valve

Blower

High

Low

Pressure/

Compressor

Low Pressure <40

PSI Lockout or

Comfort Alert

Low Pressure <40

or Comfort Alert

G Fan Aux Heat 1

Airfl ow

ECM2 RPM <100

RPM

ECM2 RPM

<100 RPM

W DHW Pump Aux Heat 2

Status

Microprocessor

Malfunction

Not Used SL1 Loop Pump(s) Aux Heat 3

DHW Limit

HWL Thermistor

>130º

HWL Thermistor

>130°F

Not Used – Aux Heat 4

DHW Off

DHW Pump

Switch Off

DHW Pump

Switch Off

–––

LED Defi nitions and Diagnostics

Standard Microprocessor