14

ENVISION RESIDENTIAL INSTALLATION MANUAL

Auxiliary Heat Ratings

KW BTU/HR Min Envision Series Compatibility

Model 208V 230V Stages 208V 230V CFM 022 026 - 030 036 - 049 060 - 072

EAM(H)5 3.6 4.8 1 12,300 16,300 450

••

EAM(H)8 5.7 7.6 2 19,400 25,900 550

••

EAM(H)10 7.2 9.6 2 24,600 32,700 650

•

EAL(H)10 7.2 9.6 2 24,600 32,700 1100

••

EAL(H)15 10.8 14.4 3 36,900 49,100 1250

••

EAL(H)15-3 10.8 14.4 3 36,900 49,100 1250

••

EAL(H)20 14.4 19.2 4 49,200 65,500 1500

•

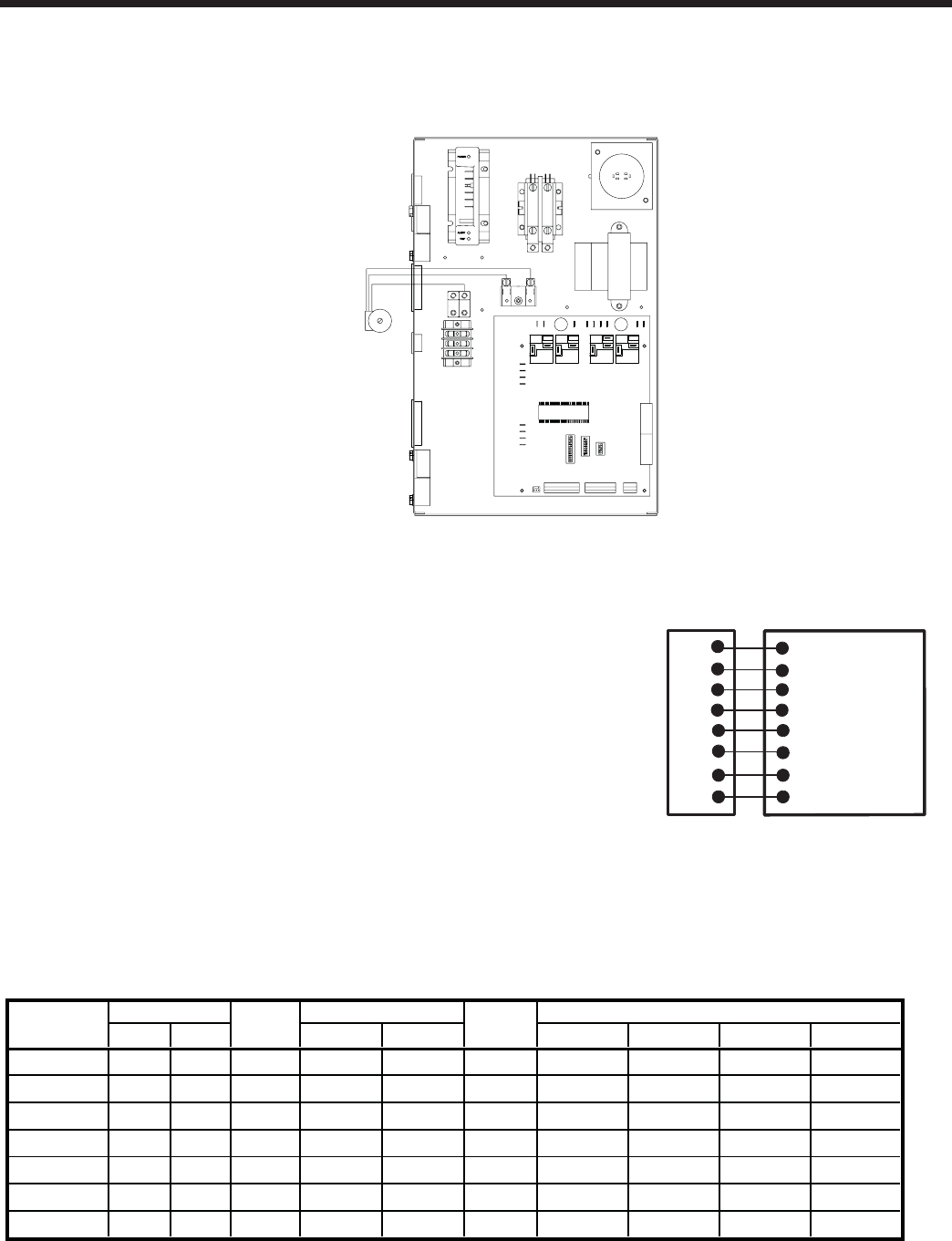

Electrical Connections (cont.)

Pump Wiring

See Figure 14 for electrical connections

from control box to pumps.

Electronic Thermostat

Position the thermostat subbase against the wall so that it is level and the

thermostat wires protrude through the middle of the subbase. Mark the position

of the subbase mounting holes and drill holes with a 3/16-inch bit. Install supplied

anchors and secure base to the wall. Thermostat wire must be 8-conductor, 18-

AWG wire. Strip the wires back 1/4-inch (longer strip lengths may cause shorts)

and insert the thermostat wires into the connector as shown. Tighten the screws

to insure secure connections. The thermostat has the same type connectors,

requiring the same wiring. See instructions enclosed in the thermostat for detailed

installation and operation information.

Note: DIP switch SW2-8 is required to be in the “OFF” position for the control to

operate with FaultFlash or ComforTalk thermostats. SW2-8 in the “ON” position confi gures the control to operate with typical

thermostats (continuous lockout signal). There must be a wire connecting Y2 on the microprocessor controller to 2nd stage

compressor on the thermostat for proper operation.

Figure 14: Pump Wiring 208-230/60/1

Figure 15: Thermostat Wiring

R

Y1

C

W

O

G

L

24VAC (Hot)

24VAC (Common)

Compressor (1st Stage)

Aux. Heat

Reversing Valve

Blower Relay

System Monitor

Microprocessor Controlle

r

Thermostat Connection

Y2

Compressor (2nd Stage)