32

ENVISION RESIDENTIAL INSTALLATION MANUAL

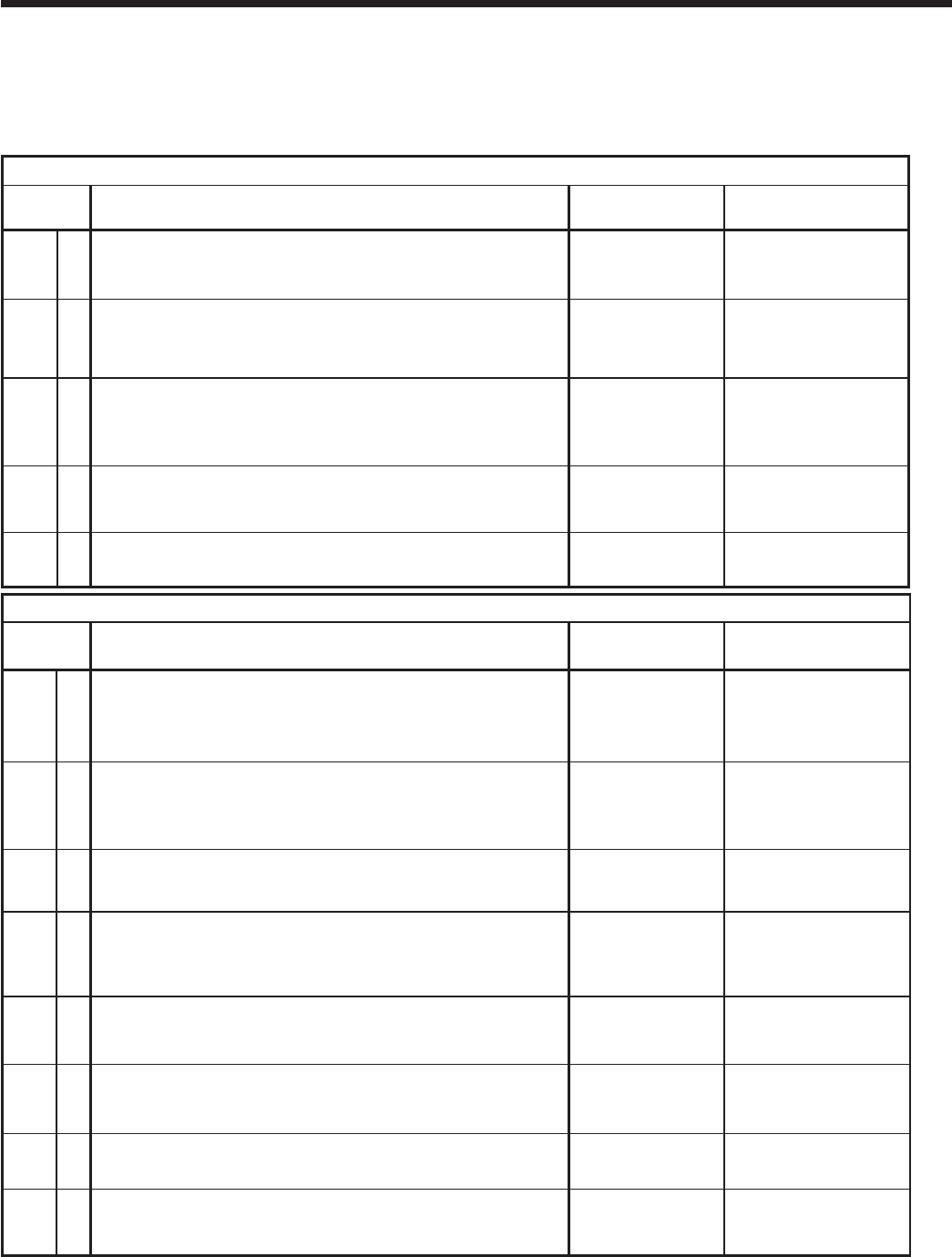

DIP Switch Settings

Prior to powering unit, ensure that all DIP switches on SW2 & SW3 are set properly according to the tables below.

FACTORY SETUP DIP SWITCHES (SW3)

DIP

SWITCH

NUMBER

DESCRIPTION OFF POSITION ON POSITION

SW 3- 1

Dual Capacity/Single-Speed

Confi gures the control for single-speed compressor operation or dual capacity opera-

tion.

Dual Capacity Opera-

tion

Single-Speed Operation

SW 3- 2

Zoned/Finish on Second Stage

This switch allows the unit to down stage with the thermostat when off and fi nish with

second stage when on. Finish on second stage reduces stage changing in recipro-

cating dual capacity compressors.

Normal - All Other

Systems

Finish on 2nd - Unzoned Dual

Capacity E Series or Premier

2 Speed

SW 3- 3

No RPM/RPM

Confi gures the control to monitor the RPM output of an ECM/ECM2 blower motor.

When using IntelliZone or a PSC fan motor, the control should be confi gured for “NO

RPM” sensing.

PSC Fan/RPM Moni-

toring Disabled

ECM-ECM2 Fan/RPM

Monitoring Enabled

SW 3- 4

Electric heat and ECM2

Allows backward compatibility with older Premier Series. In the Off position this

switch allows older electric heat board (17P501A01) and older ECM (square end)

compatibility. On is for all newer EH board (17P514A01) and ECM2 (round end).

Old EH & Old ECM Normal

SW 3- 5

On dual capacity units this switch allows stage change: on the fl y when off, and 1

minute delay when on. A delay is required on all reciprocating dual capacity units.

Envision E-Series or Premier

FIELD SELECTION DIP SWITCHES (SW2)

DIP

SWITCH

NUMBER

DESCRIPTION OFF POSITION ON POSITION

SW 2- 1

Service Test Mode

On the control, allows fi eld selection of “NORMAL” or “TEST” operational modes.

Test mode accelerates most timing functions 16 times to allow faster troubleshooting.

Test mode also allows viewing the “CURRENT” status of the fault inputs on the LED

display.

Test Mode Normal Speed Operation

SW 2- 2

Freeze Sensing Setting

Allows fi eld selection of freeze thermistor fault sensing temperatures for well water

(30°F) or antifreeze-protected (15°F) earth loops.

Loop Water Freeze

Protection 15° F

Well Water Freeze Protec-

tion 30° F

SW 2- 3

Accessory Relay

Allows fi eld selection of the accessory relay to operate with the compressor or fan.

Acc Relay Tracks Fan

Acc Relay Tracks Compres-

sor

SW 2- 4

Fan Speed Control

Allows fi eld selection of reduced fan speed (85% of selected medium and high speed

– ECM only) for cooling in the dehumidifi cation mode.

Dehumidifi cation Fan

Speeds

Normal Fan Speeds

SW 2- 5

Auxiliary Off

Disables 3rd-stage Heating. Full emergency heat would still be available if needed.

Disable Heating

Stage 3

Enable Heating

Stage 3

SW 2- 6

Diagnostics Inputs

Allows viewing the inputs from the thermostat to the control board such as Y1, Y2, O,

G, W, SL1-In on the LED display.

Diagnostic Inputs

Viewed at LEDs

Normal Display Viewed at

LEDs

SW 2- 7

Diagnostics Outputs

Allows viewing the outputs from the control board such as compressor, reversing

valve, blower, hot water pump, and loop pump on the LED display.

Diagnostic Outputs

Viewed at LEDs

Normal Display Viewed at

LEDs

SW 2- 8

Thermostat Selection

Confi gures the control for a pulsed lockout signal (ComforTalk and FaultFlash ther-

mostats) or continuous 5 VAC lockout signal.

Pulsed “L” signal Continuous “L” signal

Microprocessor Control (cont.)

NEW

]

NEW

]