Site Preparation and Installation

Liebert

®

Mini-Mate2

™

20

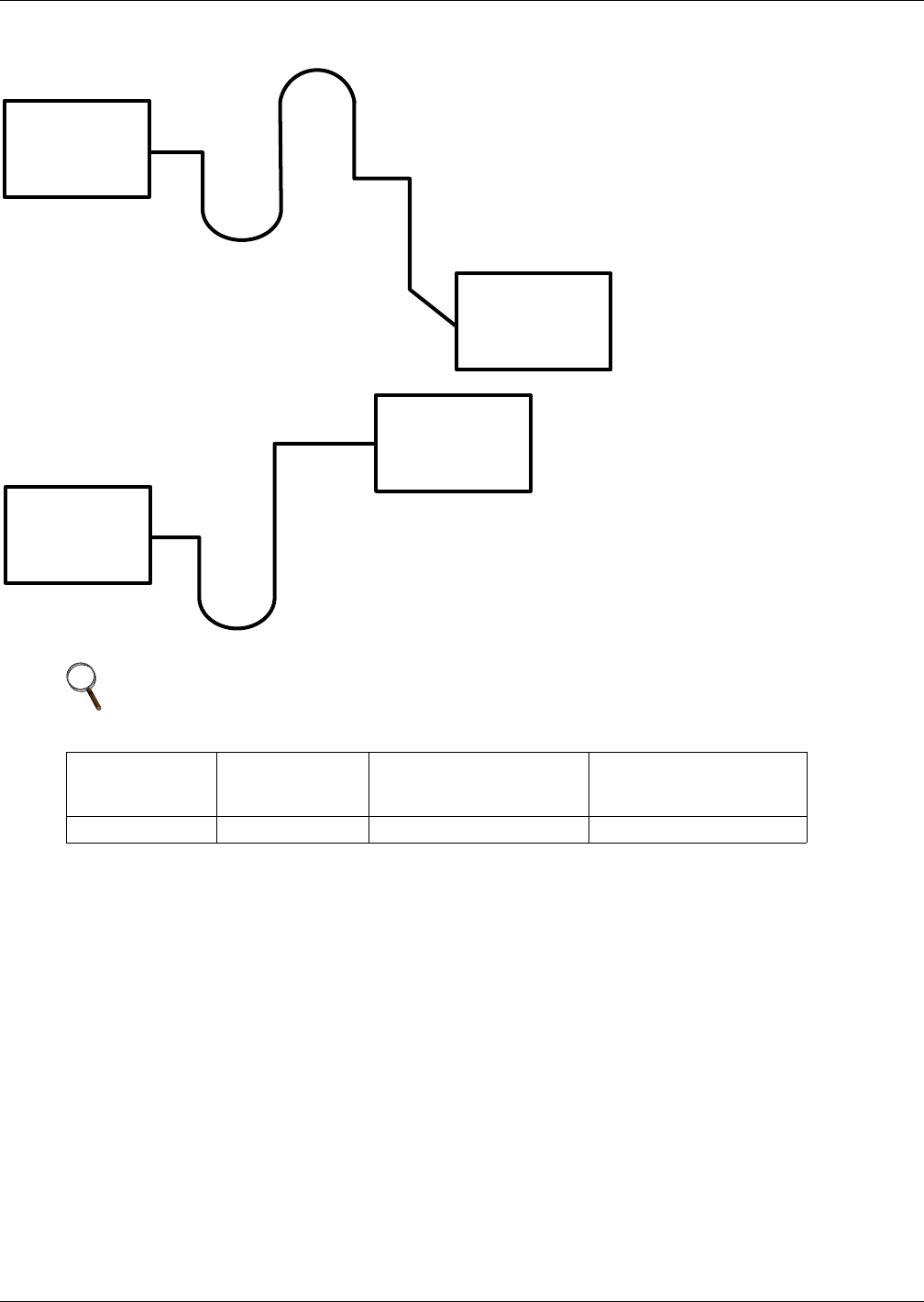

Figure 11 Refrigerant piping diagram

Refrigerant Charge Requirements—Total refrigerant charge will be required only if units are

evacuated during installation or maintenance. For safe and effective operation, refer to 5.4.3 - Piping

Connections and Coolant Requirements.

NOTE

If field supplied refrigerant piping is installed, refrigerant must be added to the system.

Table 10 Pipe length and condenser elevation relative to evaporator

Nominal System

Size Tons

Maximum

Equivalent Pipe

Length, ft. (m)

Maximum PFH Level

Above Evaporator, ft. (m)

Maximum PFH Level

Below Evaporator, ft. (m)

5 150 (45) 50 (15) 15 (4.6)

Maximum recommended total equivalent pipe length is 150 ft (46m). Suction and liquid lines may require

additional specialty items when vertical lines exceed 20 ft. (6m) and/or condensing unit installation is more than

15 ft. (4.6m) below the evaporator. Contact Emerson Application Engineering for assistance.

Evaporator

Evaporator

Condensing

Unit

NOTE

When installing remote condensing units below the

evaporator, the suction gas line should be trapped with

an inverted trap to the height of the evaporator . This

prevents refrigerant migration to the compressors

during off cycles . Maximum recommended vertical

level drop to condensing unit is 15 ft. (4.6m) .

Pitch down 1/2" (13mm) per 10 ft. (3m)

Suction Line Piping

Condensing Unit Above Evaporator

Traps recommended at the base of riser exceeding

5 ft (1.5m) and every 20 feet (6m) of vertical rise.

Suction Line Piping

Condensing Unit

Below Evaporator

Condensing

Unit

Pitch down 1/2" (13mm) per 10 ft. (3m)

See Table 10 for recommended maximum

vertical rise above evaporator/maximum

vertical fall below evaporator.